Composite packages, package laminates for composite packages, and packaging sleeve blanks

A technology for composite materials and laminated products, applied in the fields of composite material packages, package laminates for composite material packages, and packaging sleeve blanks, capable of solving suboptimal pallet availability and reducing package strength and dimensional integrity, limited stackability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

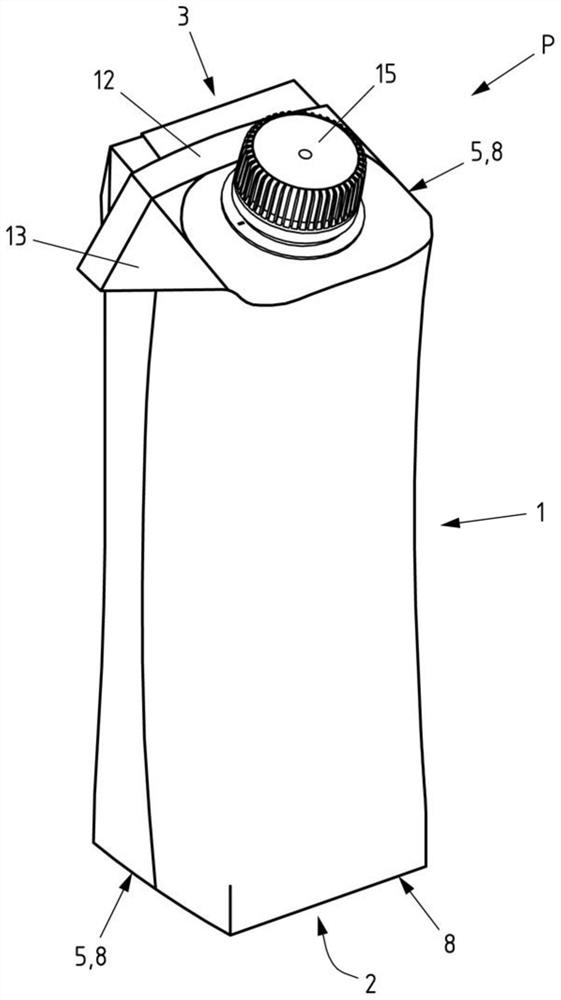

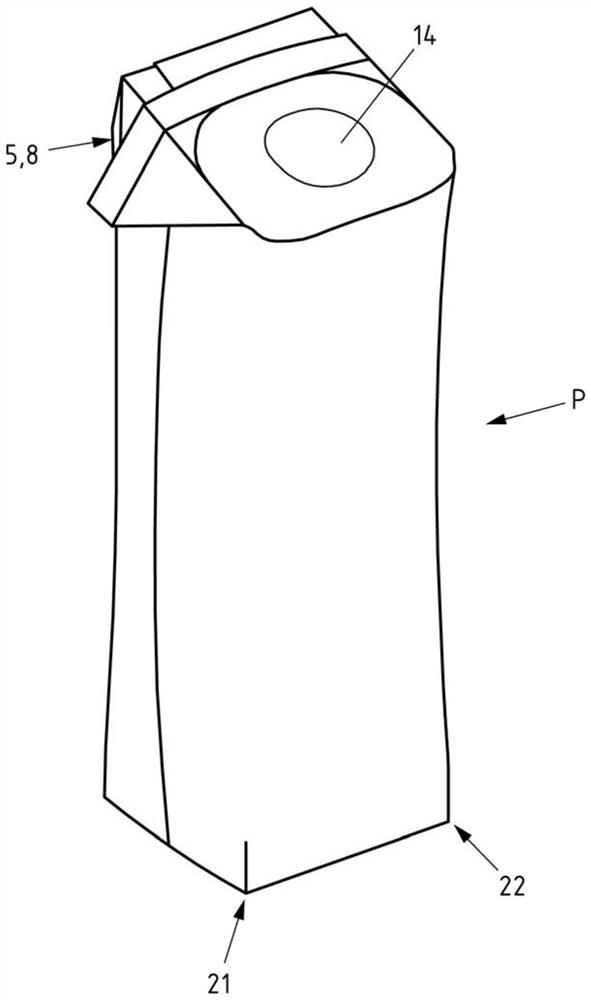

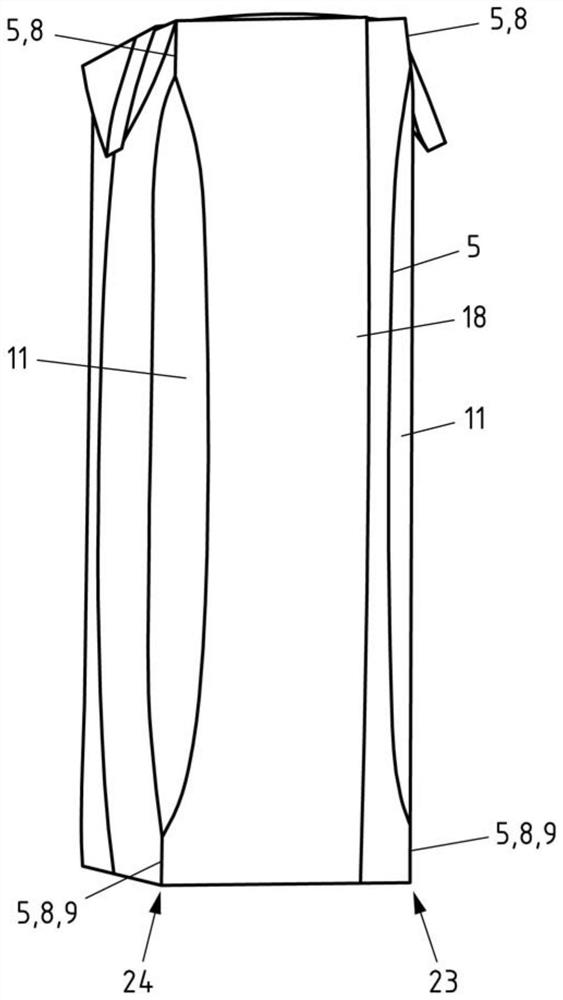

[0033] figure 1 The embodiment of a composite package P according to the invention shown in , is formed by a package base 1 , a package bottom 2 closing said package base and a package gable 3 forming the top of the package. All three parts are formed from the same packaging material through a forming-folding process. Thus, the package bottom 2 is formed via the package folding line 8 on the folding mandrel of the packaging machine and sealed by means of ultrasound (alternatively eg hot air, adhesives etc. are conceivable). The bottom-sealed semi-finished package product is then filled with the required package product via the open top area, and then a package gable 3 inclined forwards with respect to the package base 1 is formed by a further package fold line 8, The package gable 3 seals the package by means of an ultrasonically welded transverse sealing seam 12 . The excess packaging material part produced during the forming of the package gable 3 forms a package ear 13 wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com