Cyanogroup coordination compound as well as preparation method and application thereof

A technology of coordination compound and cyano group, which is applied in the direction of ferricyanide, metal cyanide, structural parts, etc., can solve the problems of poor crystallinity of ferrocyanide, low capacity of sodium ion battery, unsatisfactory cycle stability, etc., to achieve Effects of short cycle time, high capacity, and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

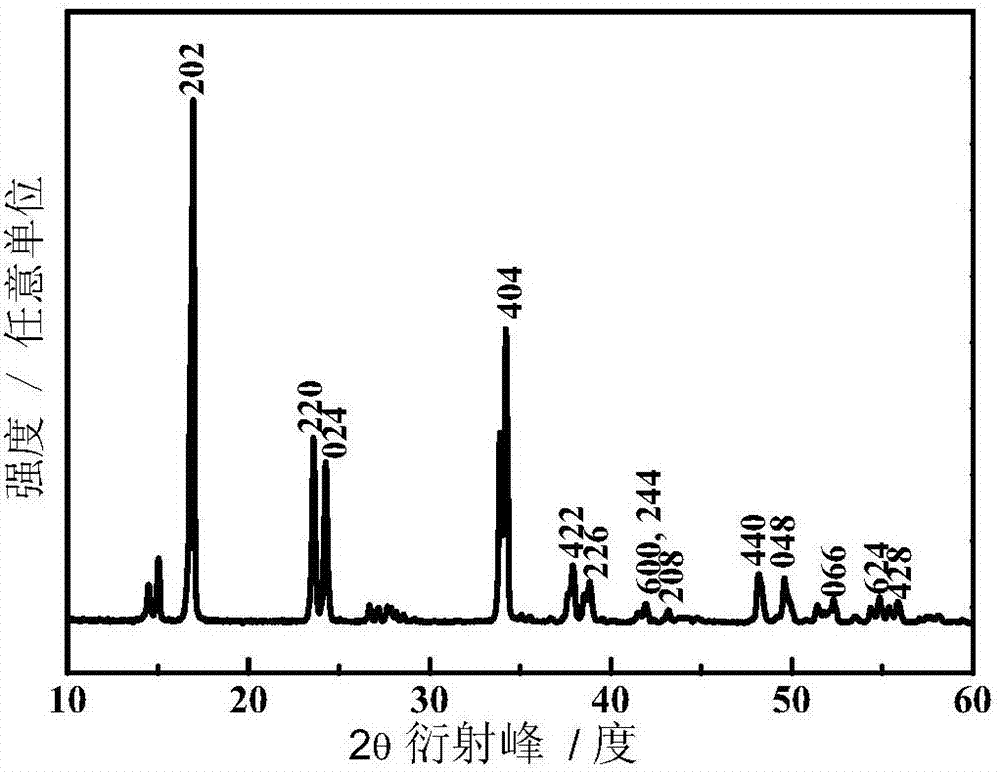

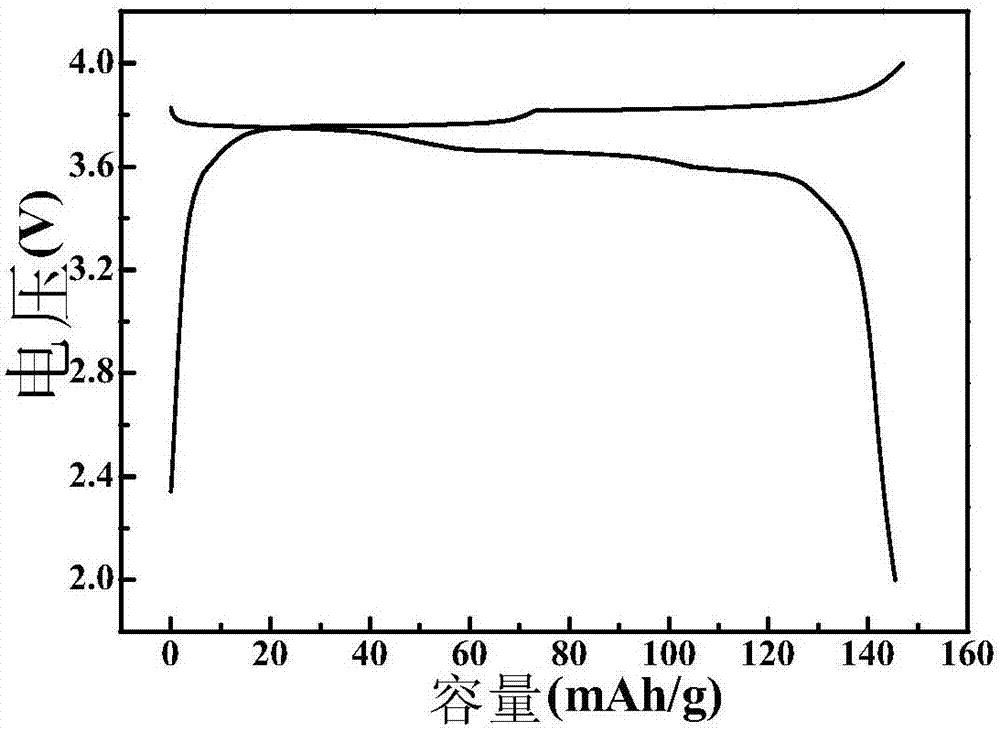

[0035] Potassium ferrocyanide was dissolved in deionized water, stirred evenly to obtain ferrocyanide ion (Fe(CN) 6 4- ) meter concentration is the solution A of 0.1mol / L; MnCl 2 Dissolved in deionized water to obtain Mn 2+ Solution B (MnCl 2 The molar ratio of potassium ferrocyanide to potassium ferrocyanide is 2.5); mix solution A and solution B, undergo a hydrothermal reaction at 60°C for 2 hours, filter, wash, and dry to obtain K x Mn[Fe(CN)] y Precipitation; NaCl is dissolved in the mixed solvent of ethylene glycol and deionized water (the volume ratio of the two is 90:10) to obtain a concentration of 0.2mol / L solution C (the mol ratio of NaCl and potassium ferrocyanide is 2.5 ), the K x Mn[Fe(CN)] y Add it into solution C, after ultrasonic dispersion, under nitrogen atmosphere, react at 150°C for 1.5h, then cool, filter, wash, and dry to obtain the nanostructured cyano coordination compound Na x Mn[Fe(CN)] y . Through ICP analysis, the x value of the product is ...

Embodiment 2

[0045] Potassium ferrocyanide was dissolved in deionized water, stirred evenly to obtain ferrocyanide ion (Fe(CN) 6 4- ) solution A with a concentration of 0.2mol / L; MnCl with a molar ratio of 1:1 2 and FeSO 4 Dissolved in deionized water to obtain Mn 2+ and Fe 2+ Solution B (MnCl 2 with FeSO 4 The ratio of the total moles of potassium ferrocyanide to the moles of potassium ferrocyanide is 3); solution A and solution B are mixed, subjected to hydrothermal reaction at 60°C for 2 hours, filtered, washed and dried to obtain K x mn 0.5 Fe 0.5 [Fe(CN)] y Precipitation; NaCl is dissolved in the mixed solvent of ethylene glycol and deionized water (the volume ratio of the two is 90:10) to obtain a concentration of 0.4mol / L solution C (the mol ratio of NaCl and potassium ferrocyanide is 3 ), the K x mn 0.5 Fe 0.5 [Fe(CN)] y Add it into solution C, after ultrasonic dispersion, react at 140°C for 2 hours under nitrogen atmosphere, then cool, filter, wash and dry to get the ...

Embodiment 3

[0048] Potassium ferrocyanide was dissolved in deionized water, stirred evenly to obtain ferrocyanide ion (Fe(CN) 6 4- ) meter concentration is solution A of 0.1mol / L; FeCl 2 dissolved in deionized water to obtain Fe 2+ Solution B (FeCl 2 The molar ratio of potassium ferrocyanide to potassium ferrocyanide is 3); solution A and solution B are mixed, subjected to hydrothermal reaction at 60°C for 2 hours, filtered, washed and dried to obtain K x Fe[Fe(CN)] y Precipitation; NaCl is dissolved in the mixed solvent of ethylene glycol and deionized water (the volume ratio of the two is 90:10) to obtain a concentration of 0.2mol / L solution C (the mol ratio of NaCl and potassium ferrocyanide is 2.5 ), the K x Fe[Fe(CN)] y Add it into solution C, after ultrasonic dispersion, under nitrogen atmosphere, react at 160°C for 1 hour, then cool, filter, wash, and dry to obtain the nanostructured cyano coordination compound Na x Fe[Fe(CN)] y , where, x=1.62, y=0.78; the lattice structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com