Lock-catch-gap water permeable brick

A technology of permeable bricks and gaps, applied to roads, pavements paved with prefabricated blocks, pavement details, etc., can solve problems such as rough permeable bricks, reduce water permeability, and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

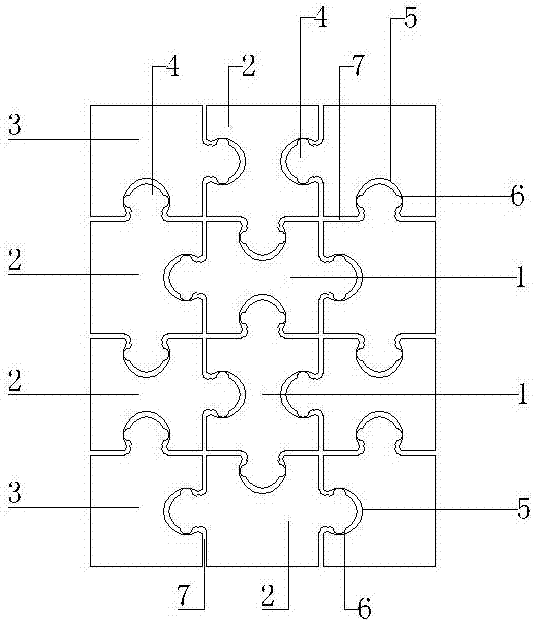

[0018] refer to Figure 1 to Figure 2 The embodiment of the locking gap permeable brick will be further described.

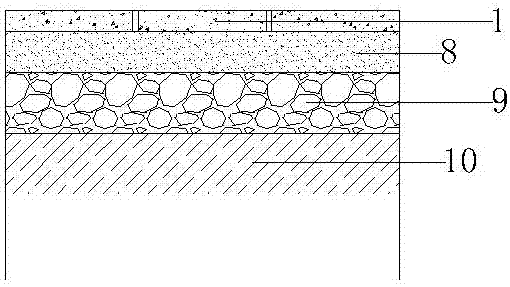

[0019] Such as figure 1 , figure 2 As shown, the permeable pavement is paved with the lock gap permeable brick 1, the lock gap permeable brick 2 with one straight line side, and the lock gap permeable brick 3 with two straight sides, including several above-mentioned lock gap permeable bricks. Brick, locking gap permeable brick 1 is a right prism with a square top and bottom, and two pairs of opposite edges of the square respectively protrude outward from the right cylinder 4 and inwardly concave and outwardly protrude from the right cylinder 4. The matching hollow straight cylinder 5 and the outwardly protruding straight cylinder 4 can be embedded in the hollow straight cylinder 5 described in the adjacent lock gap permeable brick in the vertical direction and self-lock in the horizontal direction; The lock gap permeable bricks 1 can be connected together t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap