Equal-span self-anchored span wire-arched beam cooperative system bridge

A self-anchored, suspension cable technology, applied in bridges, buildings, etc., can solve the problems of no related research on collaborative systems, large longitudinal beam tension of arch-girder composite bridges, and high main beam pressure of self-anchored suspension bridges, etc. The effect of construction materials, light weight of main beam and reasonable stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

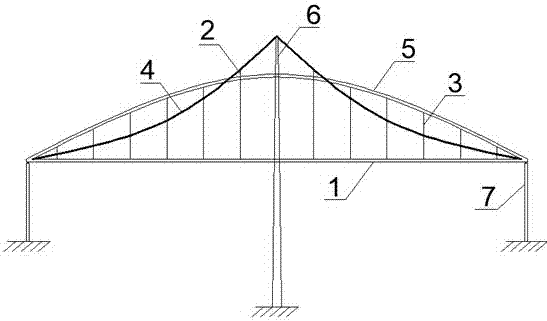

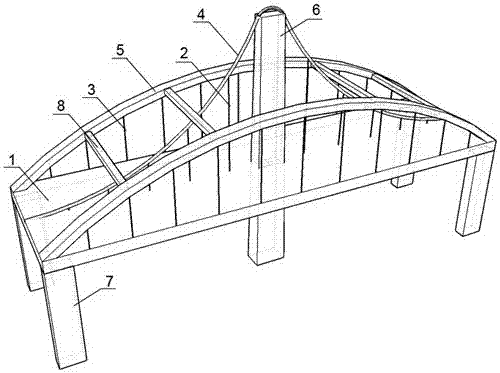

[0024] Example 1: see figure 1 , the structural system is a combination of a self-anchored suspension bridge with two towers and two cable planes and a single-arch-rib-arch-girder composite bridge. It consists of 6 towers, 7 side piers and 8 wind braces. The main girder 1 is a steel stiffened girder with a box-shaped cross-section. figure 1 Simplified as a rectangle. The bridge tower 6 is a square single-column concrete bridge tower with a variable cross-section, and the cross-section gradually increases from top to bottom, which conforms to the stress characteristics of the bridge tower. The bridge tower 6 is located in the middle of the main girder 1, ensuring that the main beam 1 on both sides of the bridge tower 6 has an equal span, and the intersection of the bridge tower 6 and the main beam 1 is not connected to the The main beam 1 is connected to make the main beam 1 fully float. The main cable 4 is supported by the pylon 6, and is erected above the middle of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com