Panel socket automatic detection production line

An automatic detection and production line technology, applied in the direction of measuring devices, comprehensive factory control, instruments, etc., can solve the problems of increasing labor intensity of workers, increasing labor costs, reducing processing efficiency, etc., saving human resources and manufacturing costs, and reducing workload. and labor intensity, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

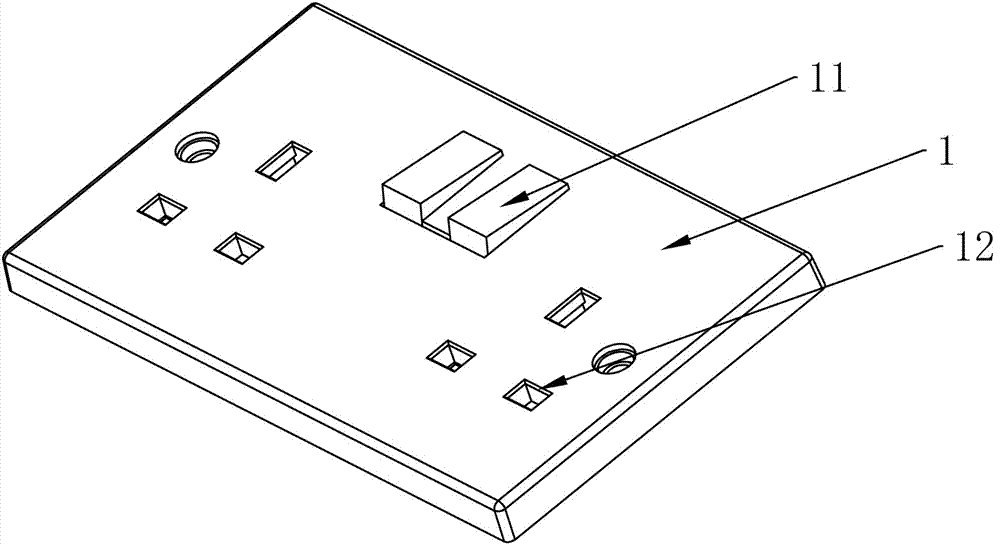

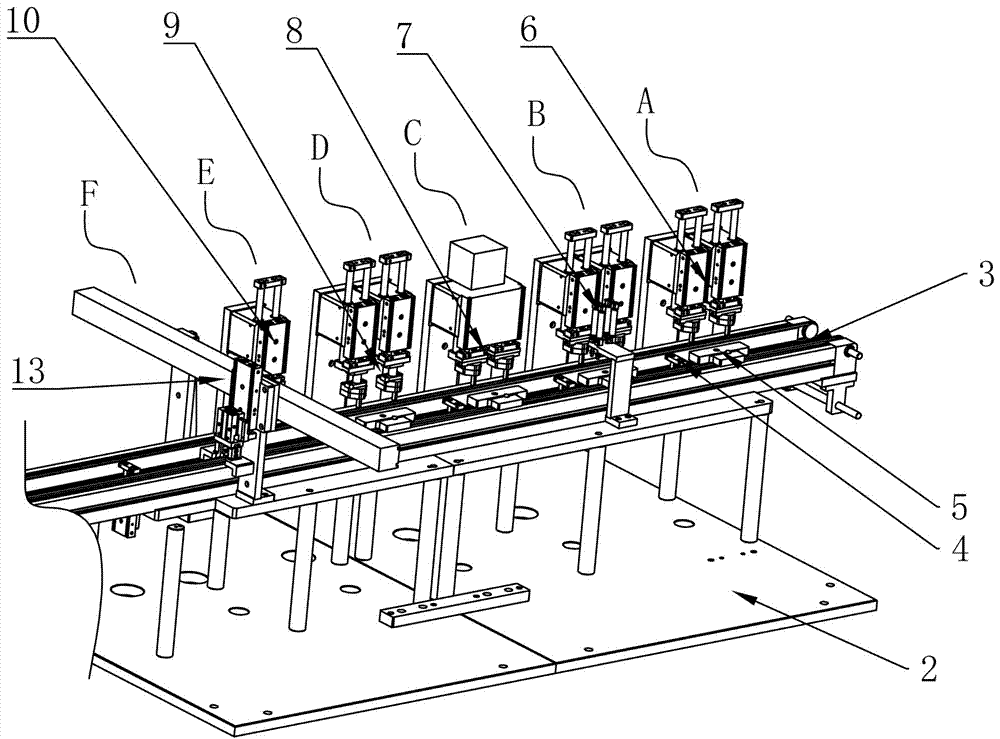

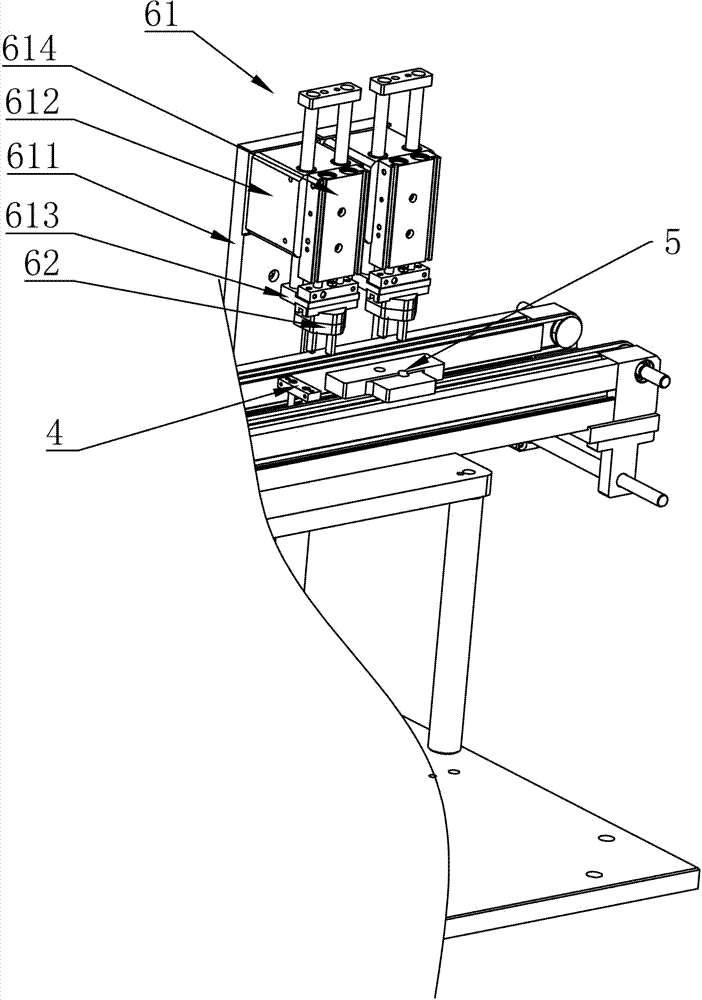

[0033] A production line for automatic detection of panel sockets. The detected panel sockets are three-pole sockets with switches. Specifically, in this embodiment, the structure of the panel sockets is as follows: figure 1 As shown, the face cover 1 is provided with two switches 11 and two three-pole jacks 12 . The structure of the panel socket detection production line can be found in Figure 2 to Figure 8 Its structure includes a frame 2 and a feeding conveyor belt 3 arranged on the frame 2. The frame 2 is provided with a power-off test station A, a power-on test station B, and a plug-in test station in sequence along the feeding direction of the feed conveyor belt 3. Pull-out test station C, high-voltage test station D, safety door test station E and screening station F. The frame 2 is also provided with a main control device.

[0034] During work, the existing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com