AGV scheduling optimization method based on two-stage multi-population parallel genetic algorithm

A genetic algorithm and optimization method technology, applied in the field of AGV car scheduling optimization, can solve problems such as slow calculation speed and premature convergence, and achieve the effects of increasing convergence speed, reducing costs, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

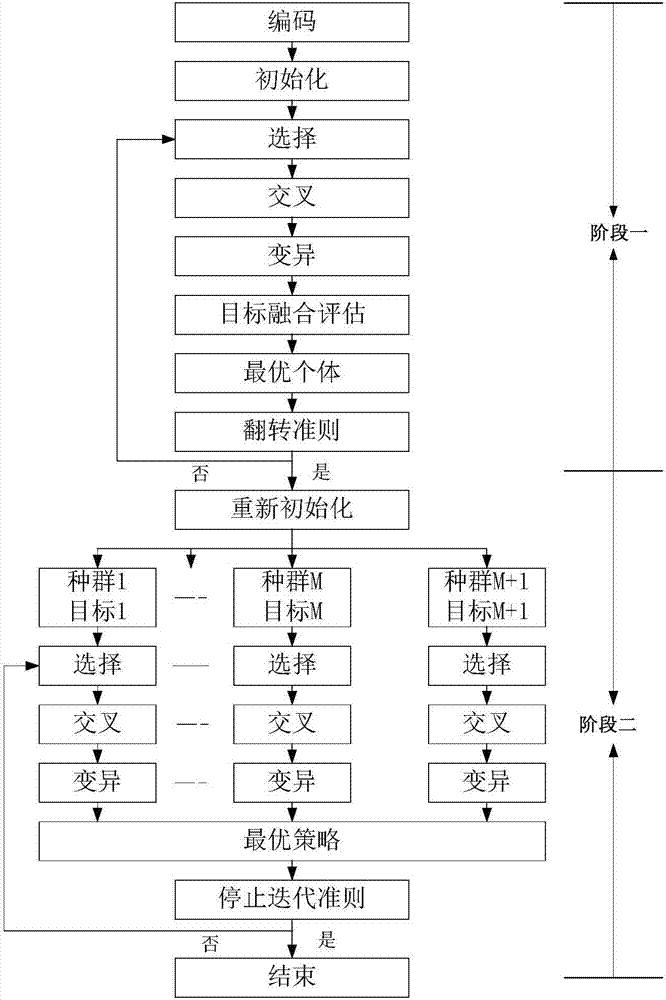

[0053] Such as figure 1 As shown in this embodiment, an AGV trolley scheduling optimization method based on a two-stage multi-population parallel genetic algorithm is disclosed, which specifically includes the following steps:

[0054] AGV trolley scheduling is described in the logistics sorting task as: Assuming that each sorting station has only one sorter, each sorter can only sort one kind of goods at the same time, and each AGV trolley can go to multiple To pick up goods locally, each AGV car needs to transport the goods on the car to different sorting stations. The goal of AGV scheduling optimization is to minimize the time required to complete the specified sorting of goods.

[0055] The optimization problem of the AGV scheduling model is:

[0056] min{max(T 1 , T 2 ,...,T k ,...,T L )}

[0057] T k =(d ik -r ik )+H k ×s k ×t ii'k +H k ×s k ×t ijk +(d jk -r jk )+H k ×s k ×t jj'k +H k ×s k ×t jik

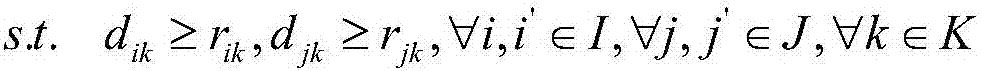

[0058]

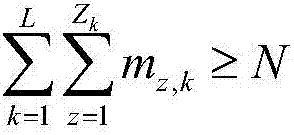

[0059]

[0060]

[0061]

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com