A Fixed Structure of Plate Potential Resistor

A fixed structure and potential technology, which is applied in the electrical component structure association, transformer/inductor parts, circuits, etc., can solve the problem of increasing the cost of the transformer due to the height of the potential resistance, and achieve the goal of reducing the height, reducing the amount, and reducing the manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

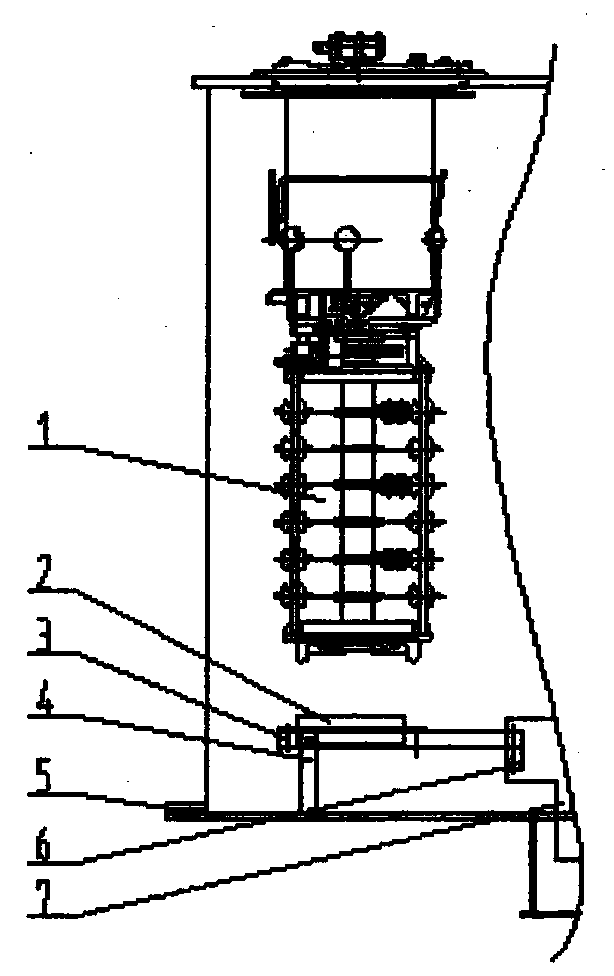

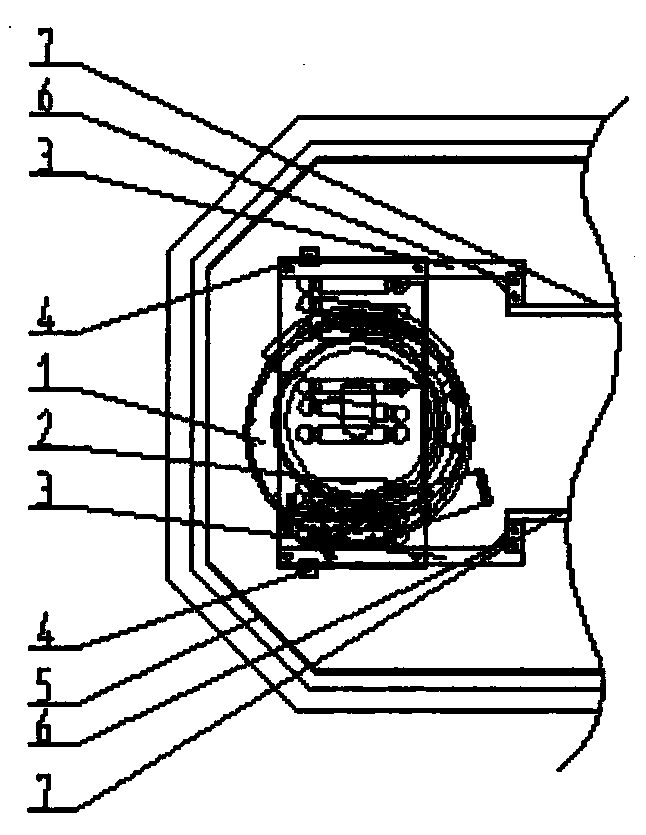

[0013] As shown in claim 1, it is a fixed structure of a plate-type potentiometer provided by the present invention. The potential resistor 2 is installed on the bottom 5 of the fuel tank, and an on-load switch 1 is installed above the potential resistor 2 in the fuel tank. The two sides of the potential resistor 2 The side is symmetrically provided with lower clamps 7, which are respectively high-voltage lower clamps and low-pressure lower clamps. A fixed plate 6 is symmetrically welded to the center lines of the high-pressure lower clamps and low-pressure lower clamps; the fixed plate 6 is symmetrical Install an L-shaped electrical laminated wood piece 1, and fasten it with blackened bolts, nuts and washers; the potential resistor 2 is placed on the two electrical laminated wood pieces 1 3, and fastened with insulating screws and nuts (the installation hole that matches with potential resistance 2 is arranged on the electrical laminated wood piece-3); Between the electrician ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com