Test device for high temperature acceleration sensor

A technology of acceleration sensor and test device, which is applied in the testing/calibration of speed/acceleration/shock measurement equipment, speed/acceleration/shock measurement, measurement device, etc. , can not carry out high temperature acceleration sensor calibration and performance test and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

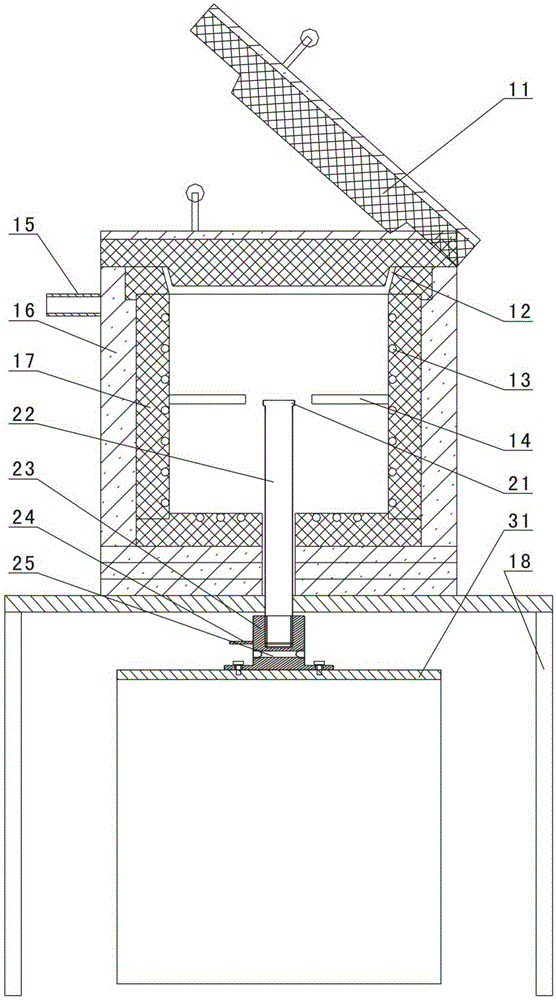

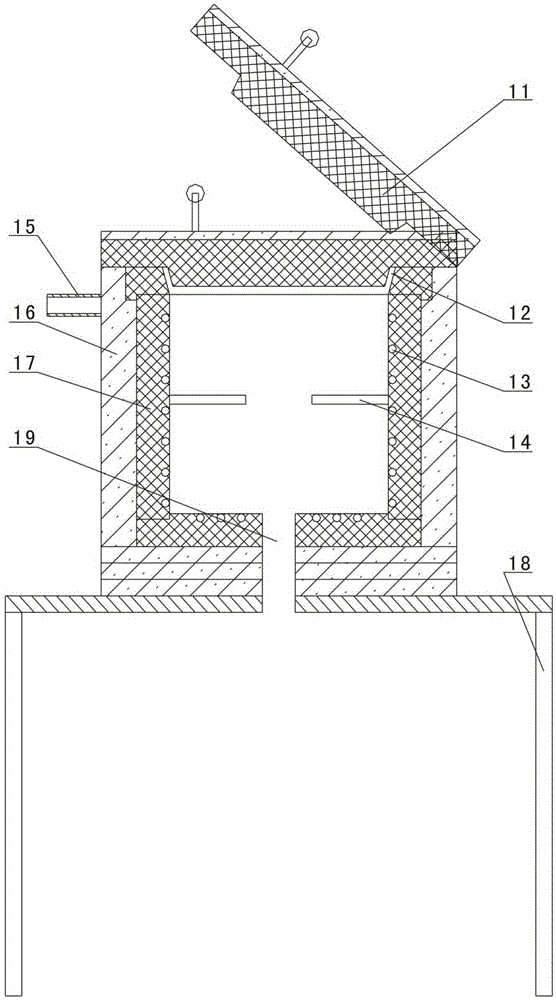

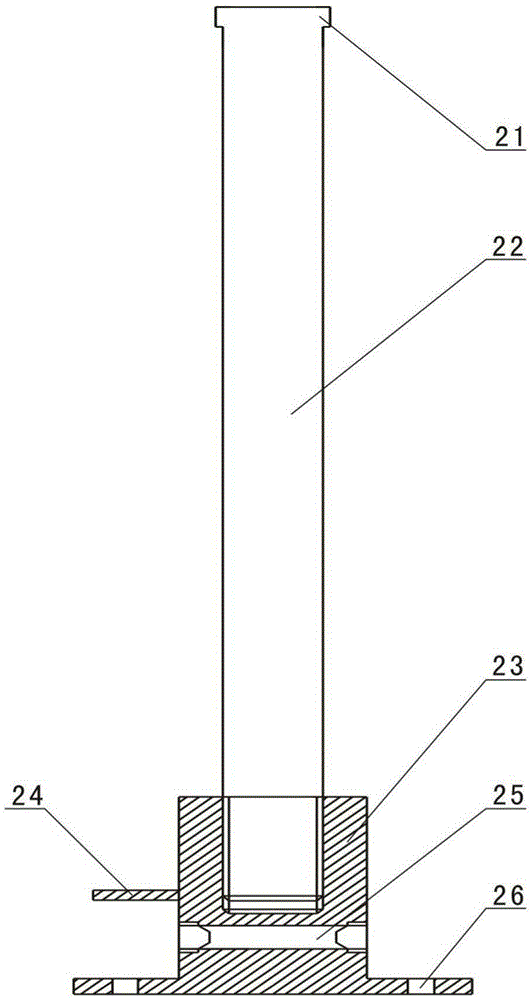

[0020] Such as figure 1 , figure 2 with image 3 As shown, the test device of the high-temperature acceleration sensor of the present invention includes a vibration table 31, a connection fixture installed on the vibration table 31, an electric furnace 17 and a support 18, and the connection fixture includes a water-cooled base 23 and a water-cooled base 23. The temperature-resistant support rod 22, the water-cooled base 23 are installed on the vibrating table 31 by screws, the water-cooled base 23 is provided with a circulating water tank 25 for cold water storage or flow, and the side wall of the water-cooled base 23 is provided with a standard acceleration sensor installation platform 24 , the top of the temperature-resistant support rod 22 is provided with the acceleration sensor mounting platform 21 to be measured (the acceleration sensor mounting platform 21 to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com