A paper machine high-efficiency steam piping system

A steam pipeline, high-efficiency technology, applied in the direction of paper machines, paper making, textiles and paper making, etc., can solve the problems of reduced equipment usage, affecting work efficiency, affecting paper quality, etc., and achieve stable drive balance, increased service life, and absorption efficiency fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

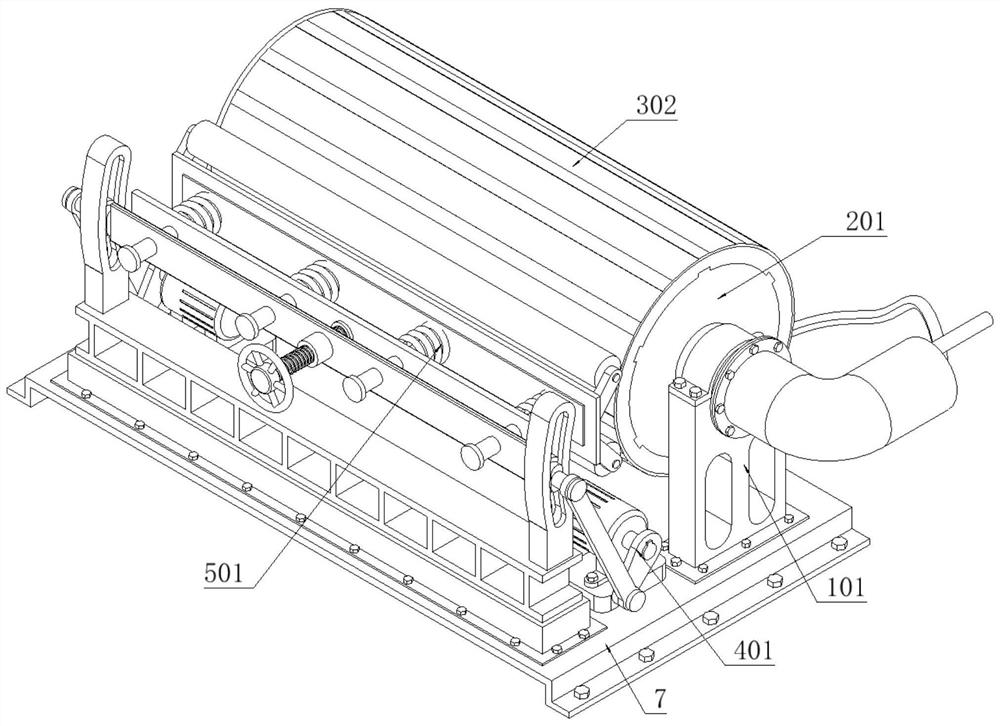

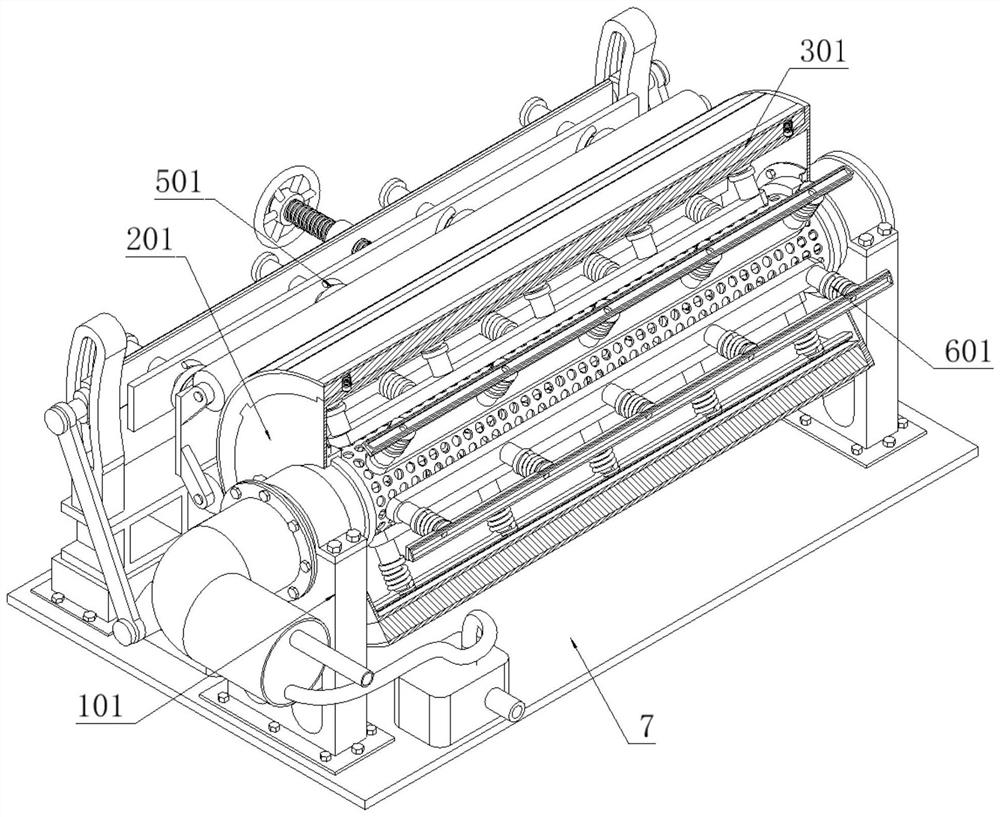

[0092] as attached figure 1 to the attached Figure 10 shown:

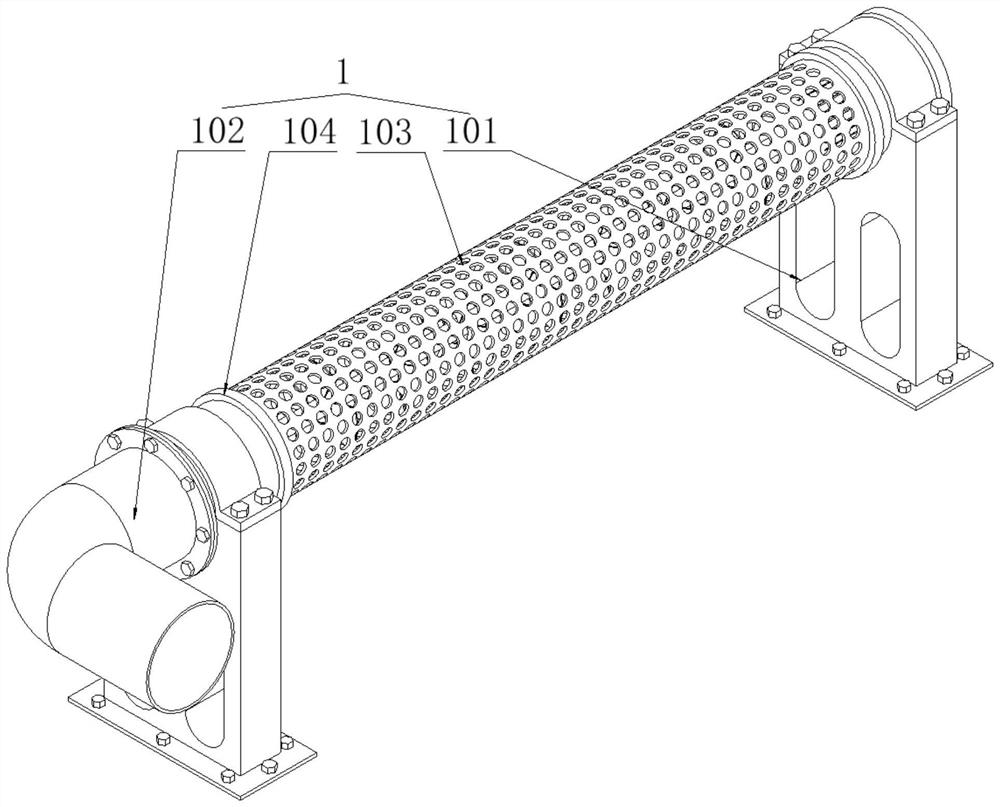

[0093] The present invention provides a high-efficiency steam piping system for a paper machine, comprising an air inlet device 1;

[0094] Air intake device 1, the air intake device 1 is fixedly connected to the installation base plate 7 by bolts;

[0095] The sealing rotary device 2, the rotary shaft of the sealing rotary device 2 is connected to the air intake device 1;

[0096] A sliding gasket device 3, the sliding gasket device 3 is slidably sleeved on the sealing rotating device 2;

[0097] The circulating propulsion device 4, the bottom of the circulating propulsion device 4 is fixedly connected to the installation base plate 7;

[0098] The pressure wrinkle removal device 5, the two sides of the pressure wrinkle removal device 5 are fixedly connected to the circulating propulsion device 4;

[0099] The condensed water removal device 6 is provided with six groups, and the six groups of the condensed w...

Embodiment 2

[0145] like Figure 11 As shown, on the basis of the first embodiment, other structures remain unchanged. This embodiment provides another structural form of the arc-shaped sliding rail 403. A crossbar is fixedly connected to the top of the arc-shaped sliding rail 403. By setting the crossbar The strength of the two arc-shaped sliding rails 403 in actual use can be greatly improved, so that the service life of the equipment is longer.

Embodiment 3

[0147] like Figure 12 As shown, on the basis of the first embodiment, other structures remain unchanged. This embodiment provides another structural form of the rubber scraping grooves 606. A sponge strip is fixedly connected to the inner side of the six rubber scraping grooves 606. By setting the sponge grooves It can better absorb the condensed water on the inner wall of the rotating drum 20, clean it more thoroughly, and achieve the best effect of steam heating and drying.

[0148] When using: First, the equipment is fixedly connected through the bolts on both sides of the installation bottom plate. After the connection is completed, the equipment can be started, and steam is introduced through the steam inlet pipe 108. During the introduction of the steam, the spoiler motor 105 drives the spoiler vanes. 106 Disturb the incoming steam, and after preheating for a period of time, the paper can be put out for drying operation. During the process, the paper will be attached to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com