An easy-to-disassemble steel pipe motor assembly

A technology of easy disassembly and assembly of steel pipes, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve problems such as poor stability and single installation method, achieve high installation stability, reduce volume, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

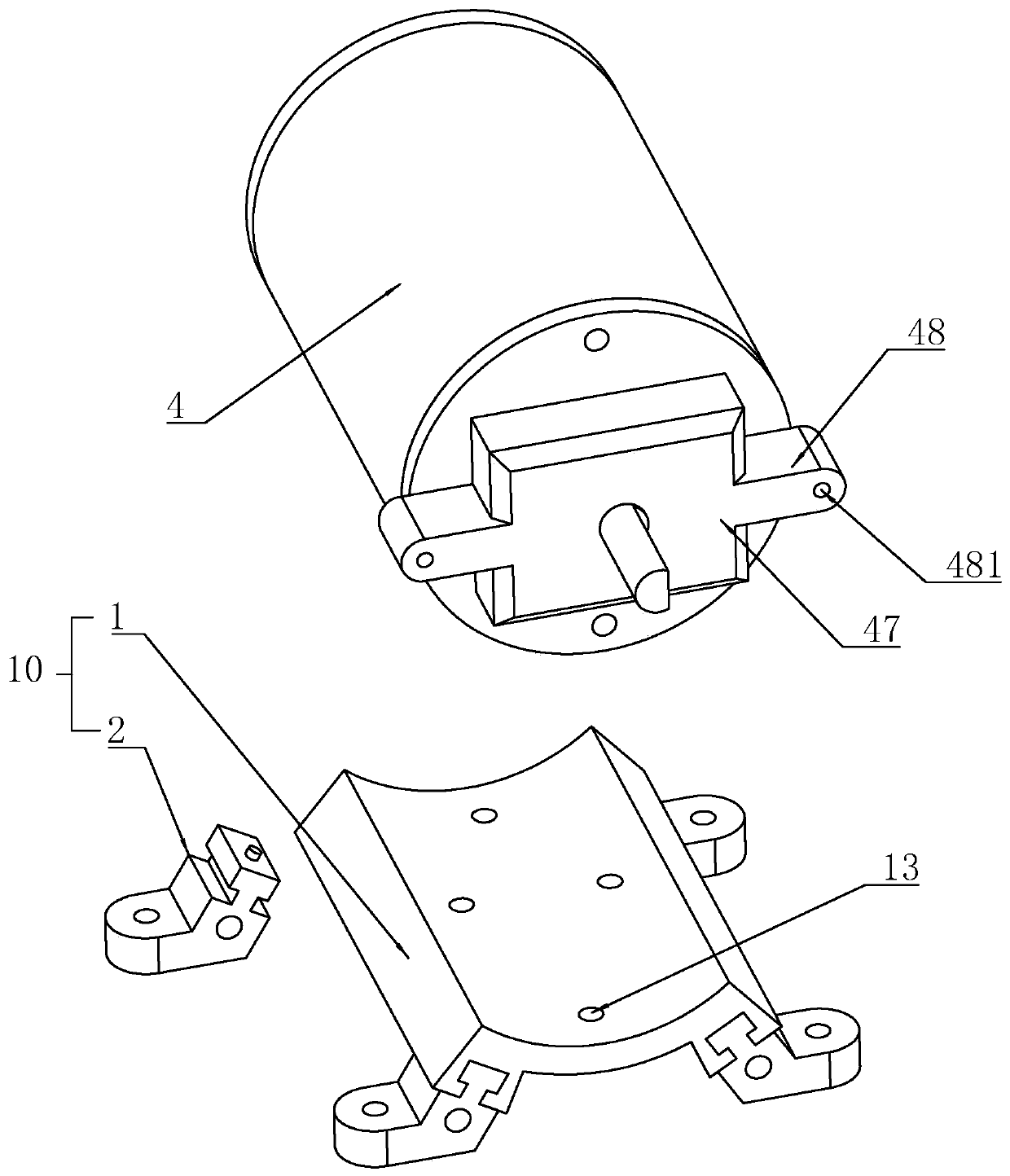

[0037] Embodiment 1: A steel pipe motor assembly that is easy to disassemble, such as figure 1 and 2 As shown, it includes a housing 4 and a mounting frame 10; four assembly holes 43 are provided on the side of the housing 4, and the four assembly holes 43 are symmetrically distributed along the axial and circumferential directions respectively; the mounting frame 10 is provided with corresponding perforations 11. The housing 4 is connected to the installation frame 10 by passing bolts through the assembly hole 43 and the through hole 11 .

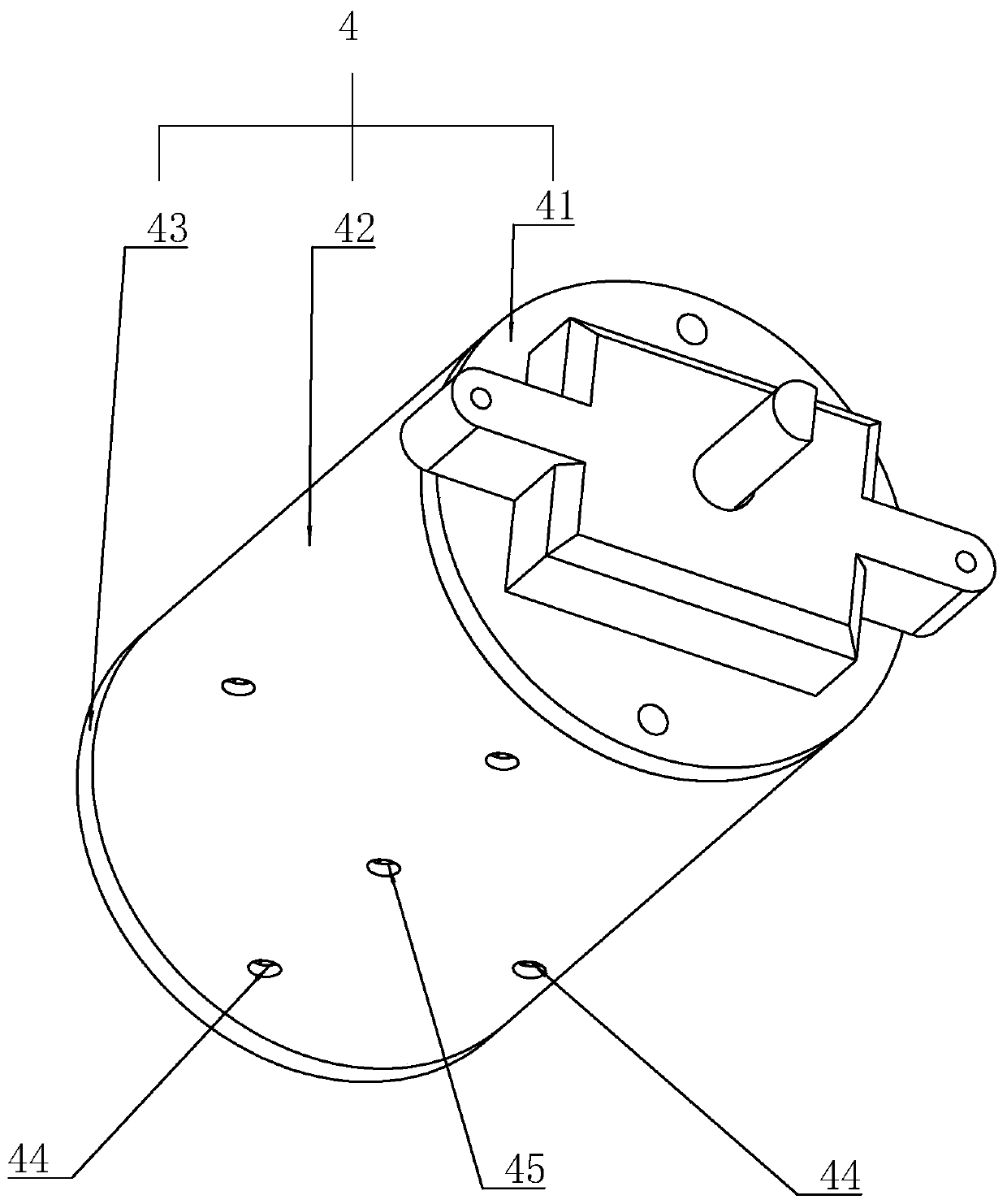

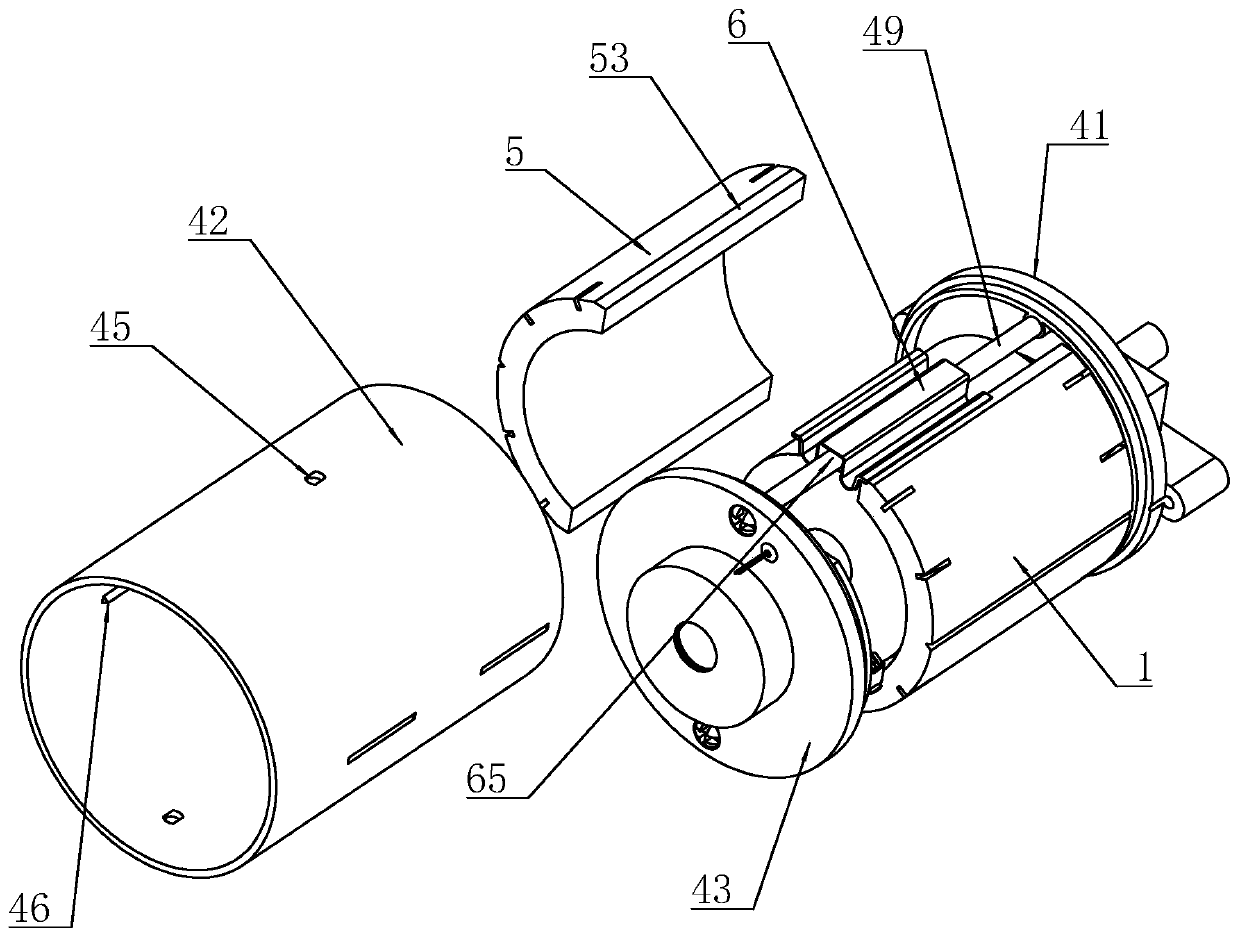

[0038] refer to image 3 , the housing 4 includes a front cover 41 , a sleeve 42 and a rear end cover 43 ; the end of the sleeve 42 is embedded in the front cover 41 and the rear end cover 43 . The inner wall of the sleeve 42 is provided with two positioning ribs 46 along the axial direction. The positioning ribs 46 are arranged symmetrically in two groups. refer to Figure 4 The inner wall of the sleeve 42 is provided with two magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com