Patents

Literature

37results about How to "Eliminate footprint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

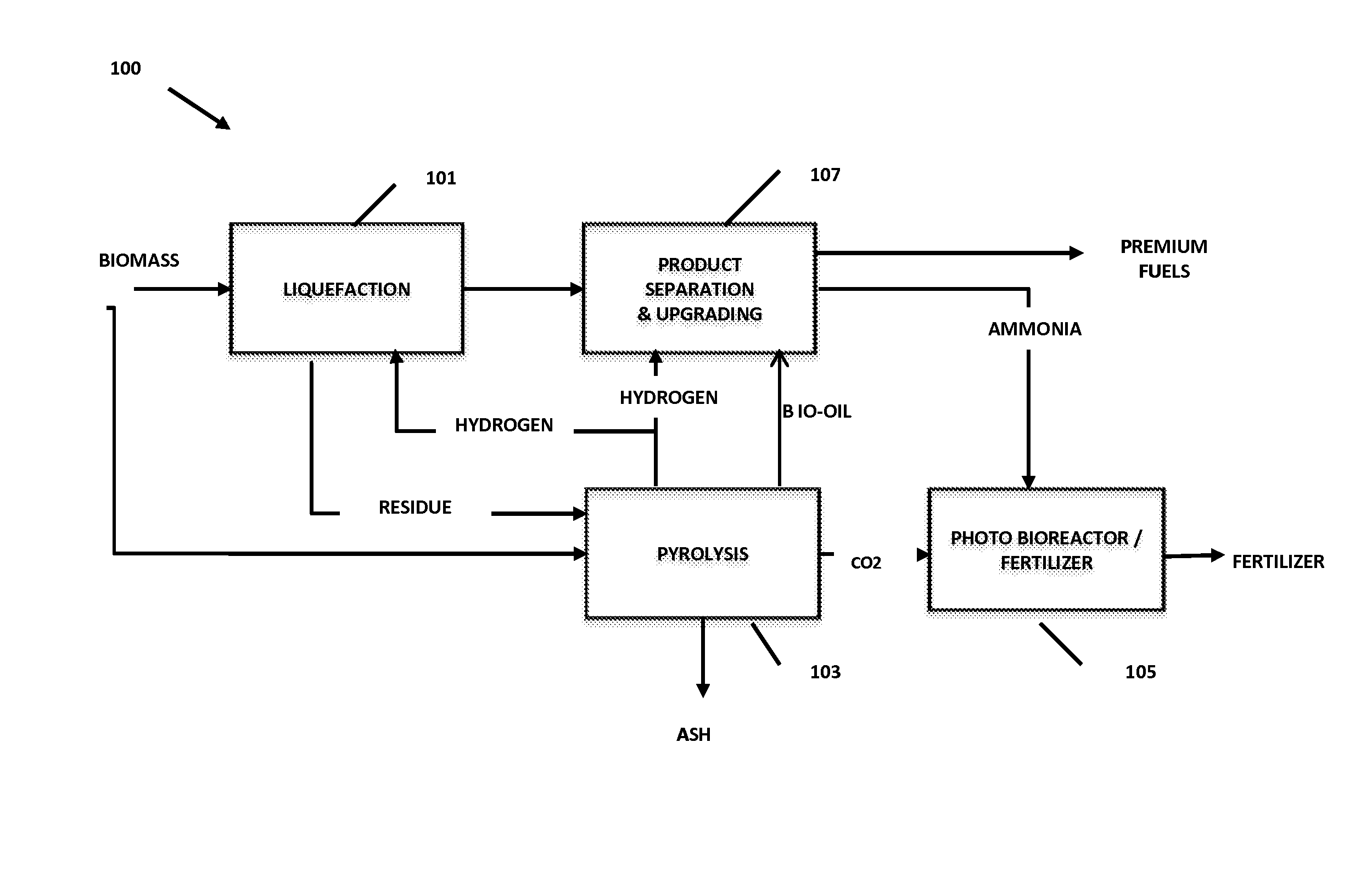

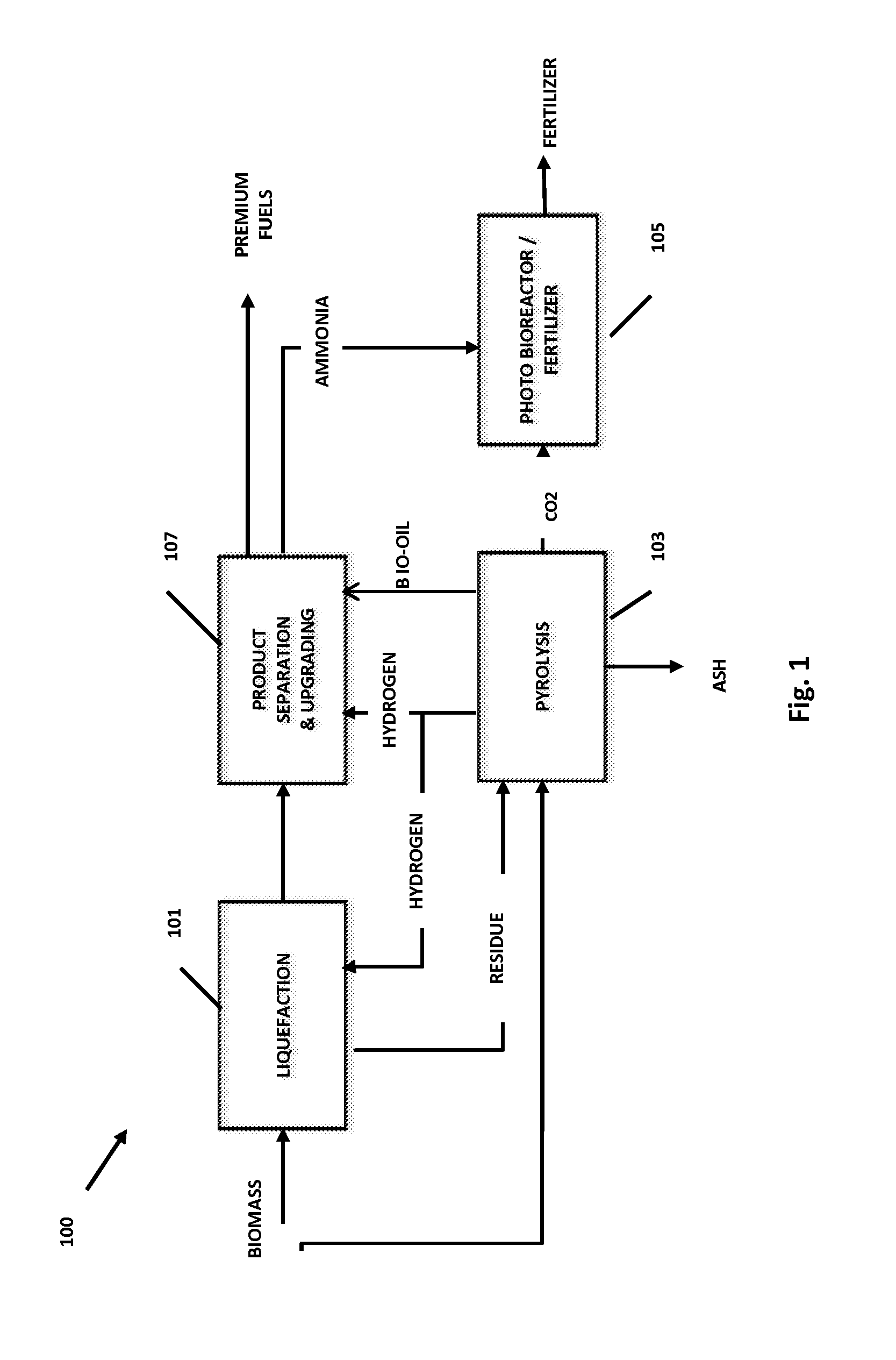

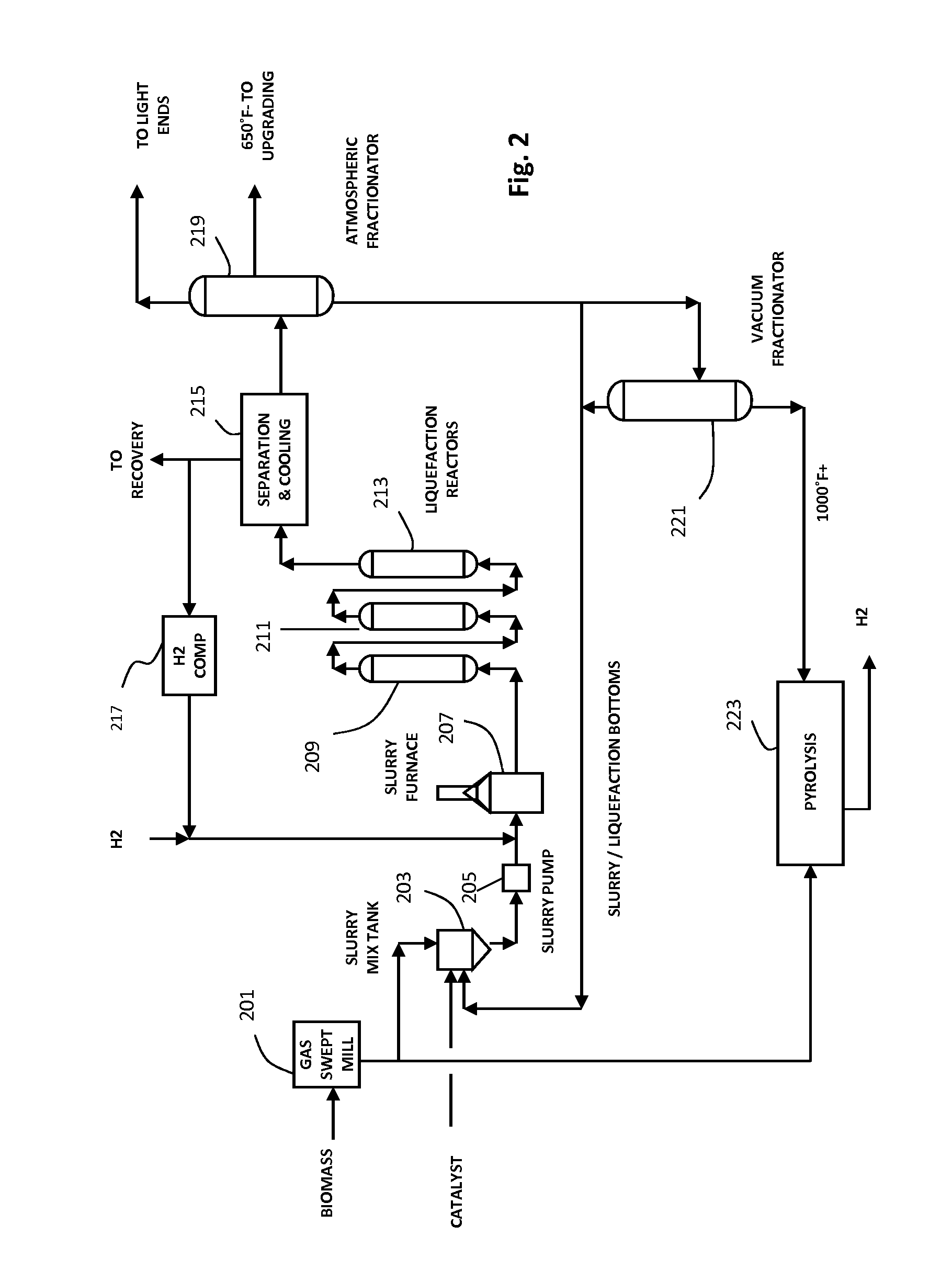

Integrated processes for producing fuels and biofertilizers from biomass and products produced

ActiveUS20140345341A1Magnifies overall carbon sequestration potentialMaximize useElectrical coke oven heatingBio-organic fraction processingLiquid fuelBiochar

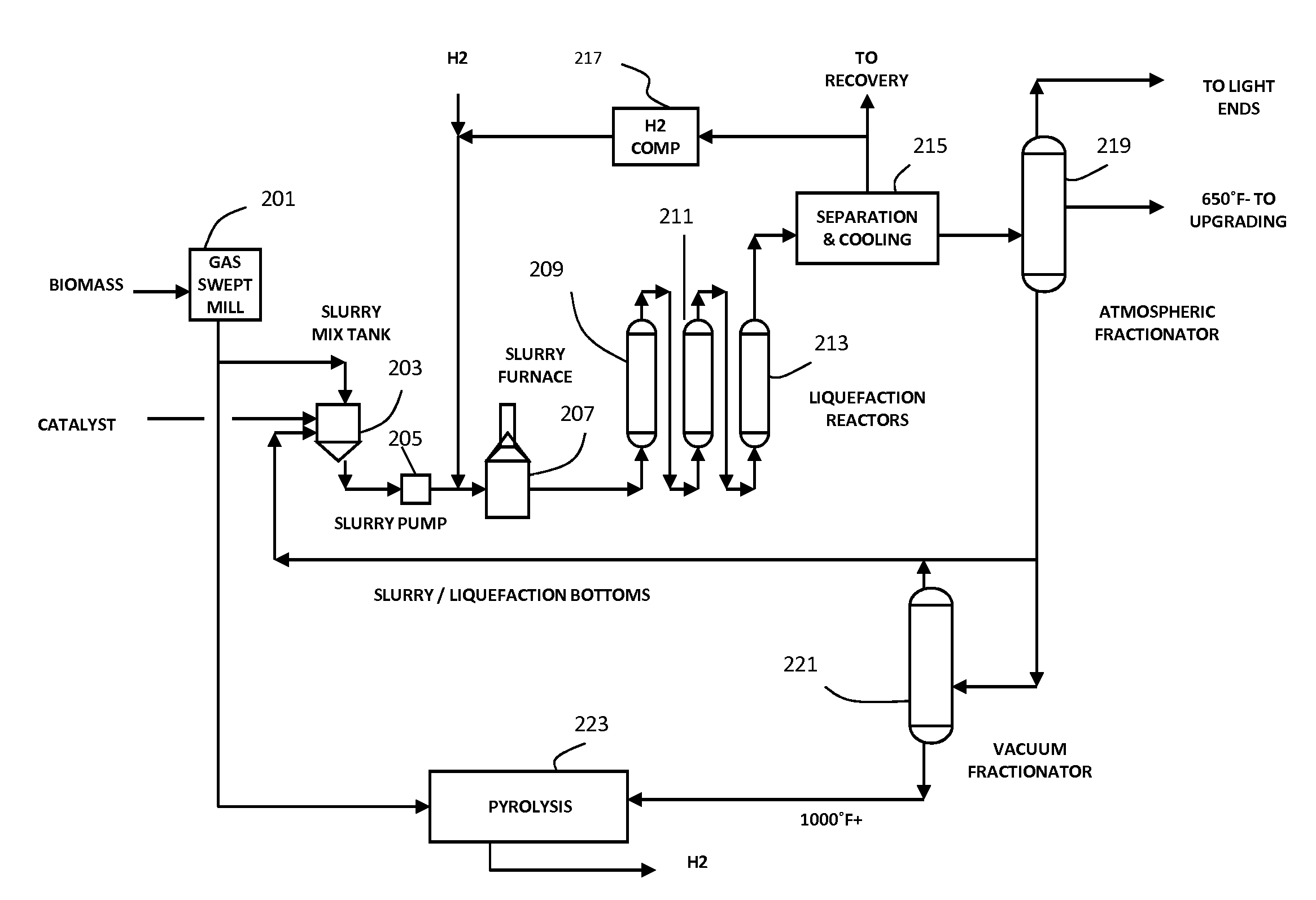

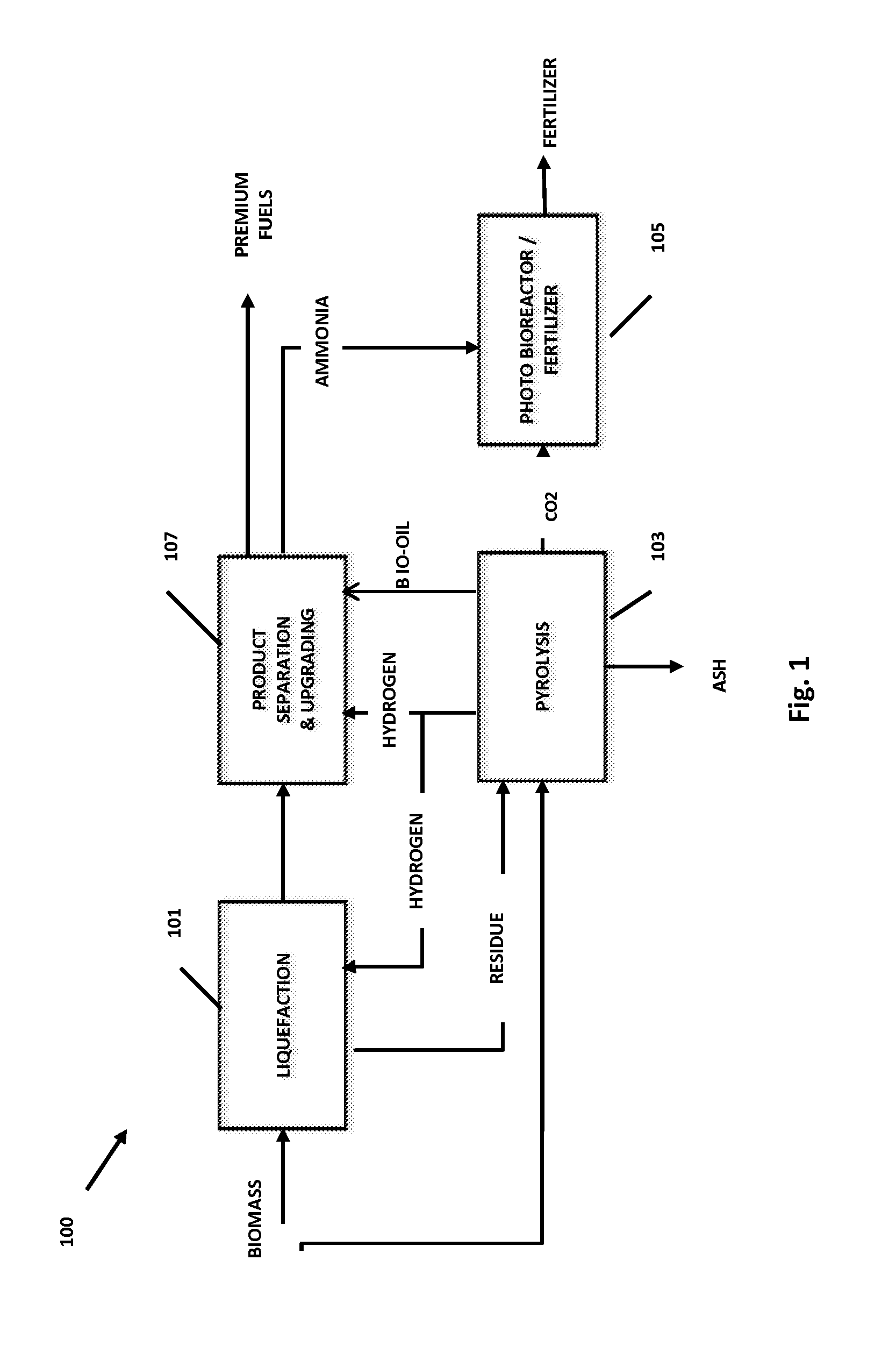

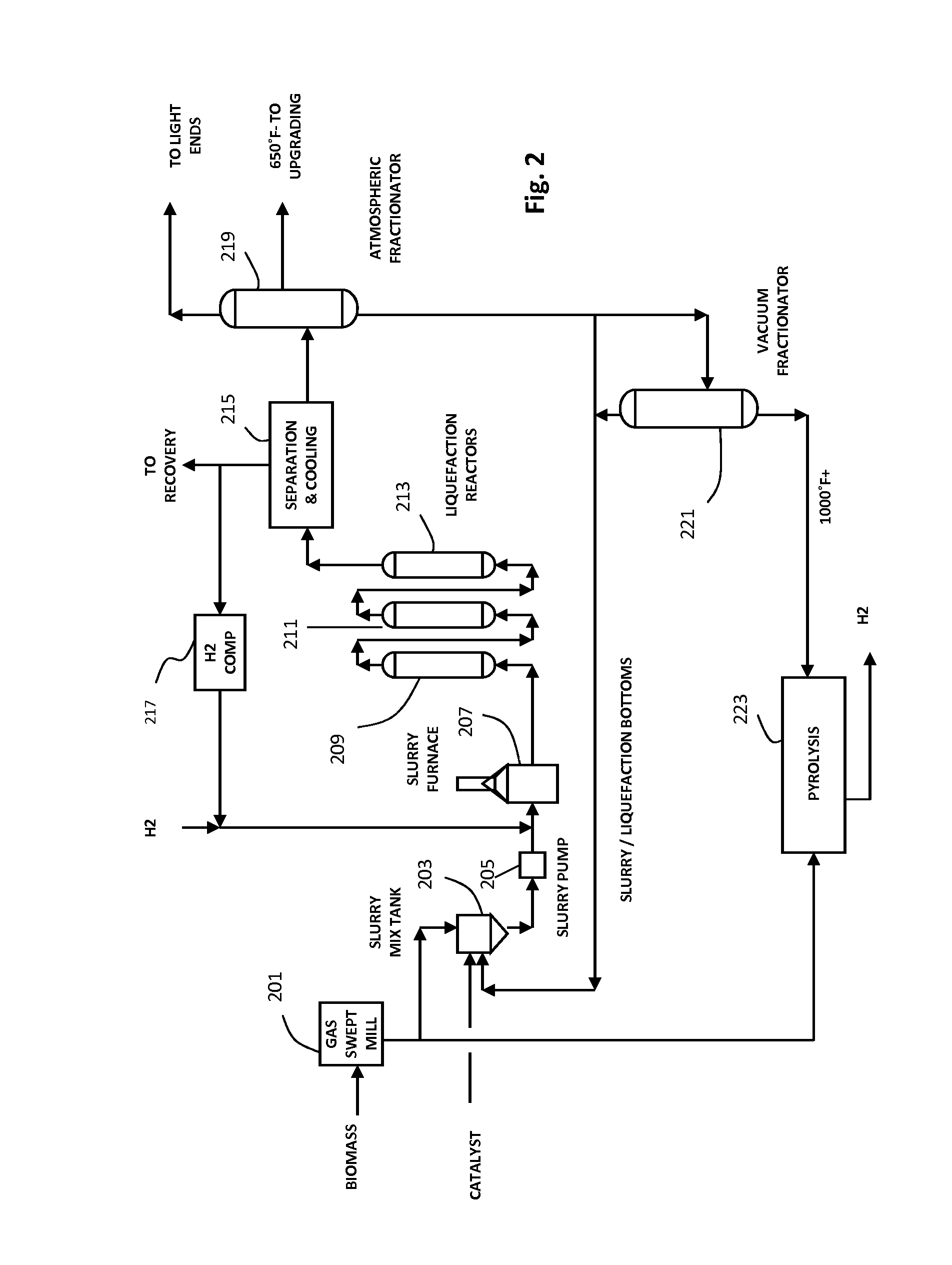

An IBTL system having a low GHG footprint for converting biomass to liquid fuels in which a biomass feed is converted to liquids by direct liquefaction and the liquids are upgraded to produce premium fuels. Biomass residues from the direct liquefaction, and optionally additional biomass is pyrolyzed to produce structured biochar, hydrogen for the liquefaction and upgrading, and CO2 for conversion to algae, including blue green algae (cyanobacteria) in a photobioreactor (PBR). Produced algae and diazotrophic microorganisms are used to produce a biofertilizer that also contains structured biochar. The structured biochar acts as a nucleation agent for the algae in the PBR, as a absorption agent to absorb inorganics from the biomass feed to direct liquefaction or from the liquids produced thereby, and as a water retention agent in the biofertilizer. The ratio of cyanobacteria to diazotrophic microorganisms in the biofertilizer can be selected to optimize the so as to achieve desired total chemically active carbon and nitrogen contents in the soil for a given crop.

Owner:ACCELERGY CORP +1

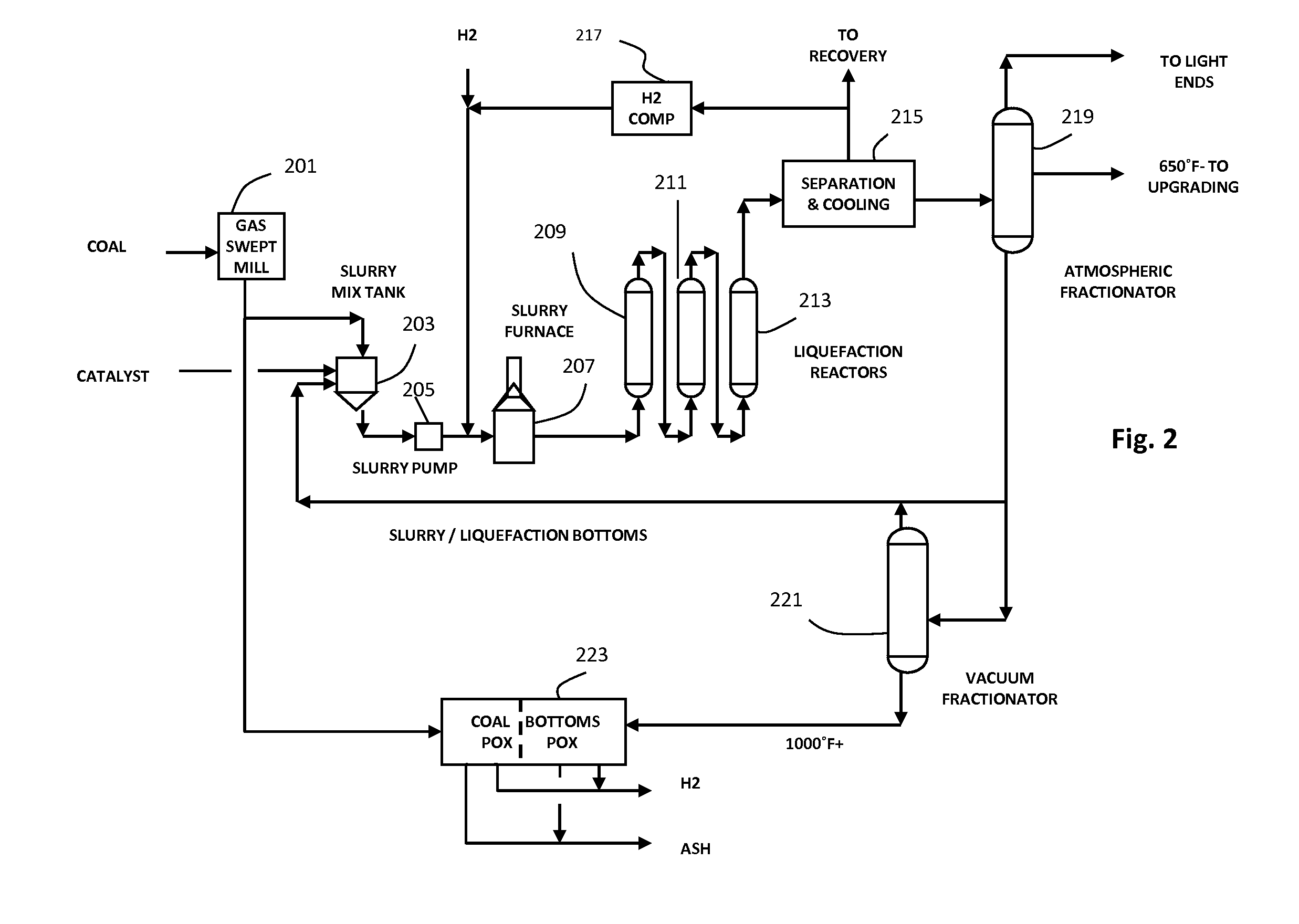

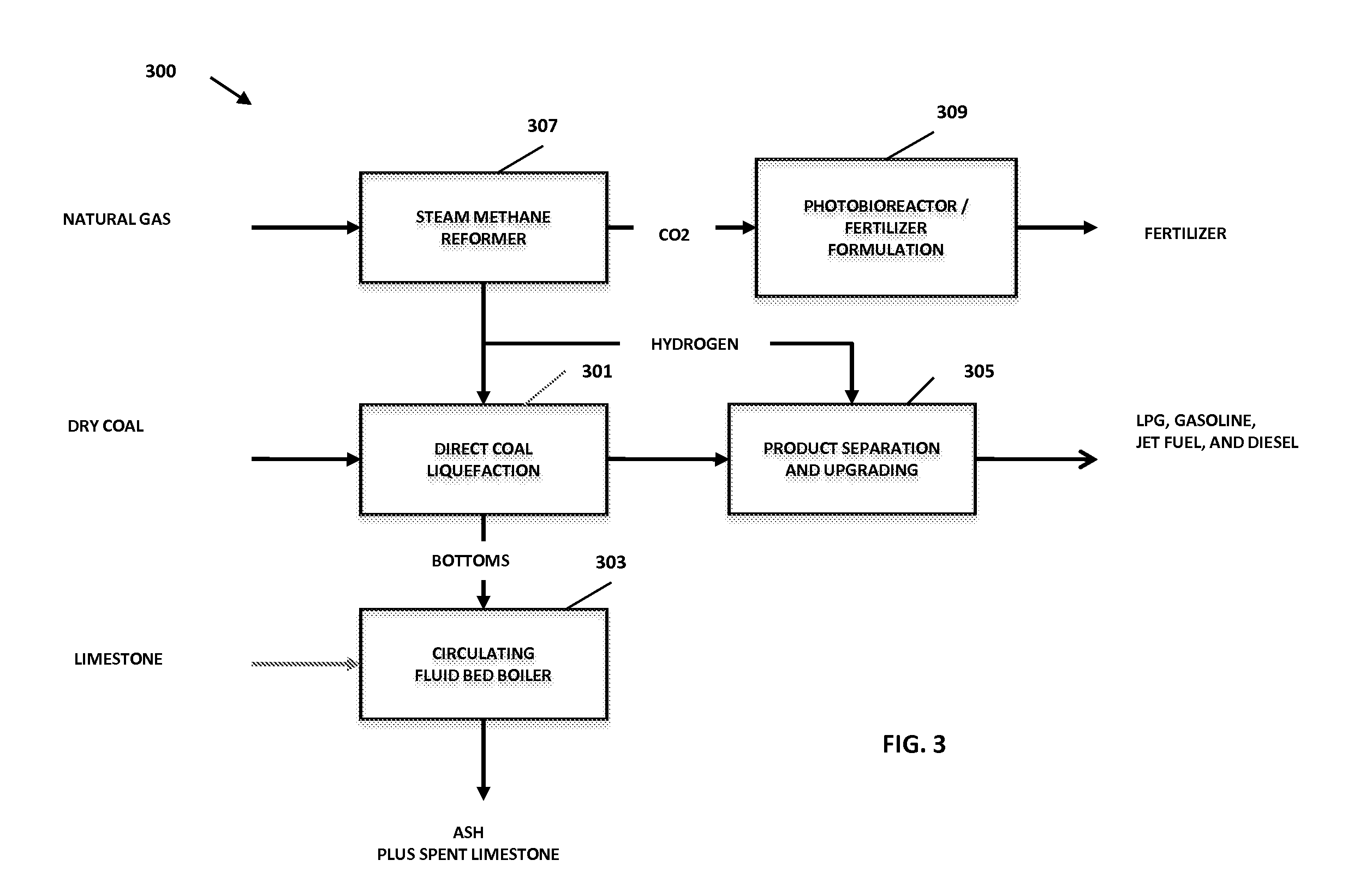

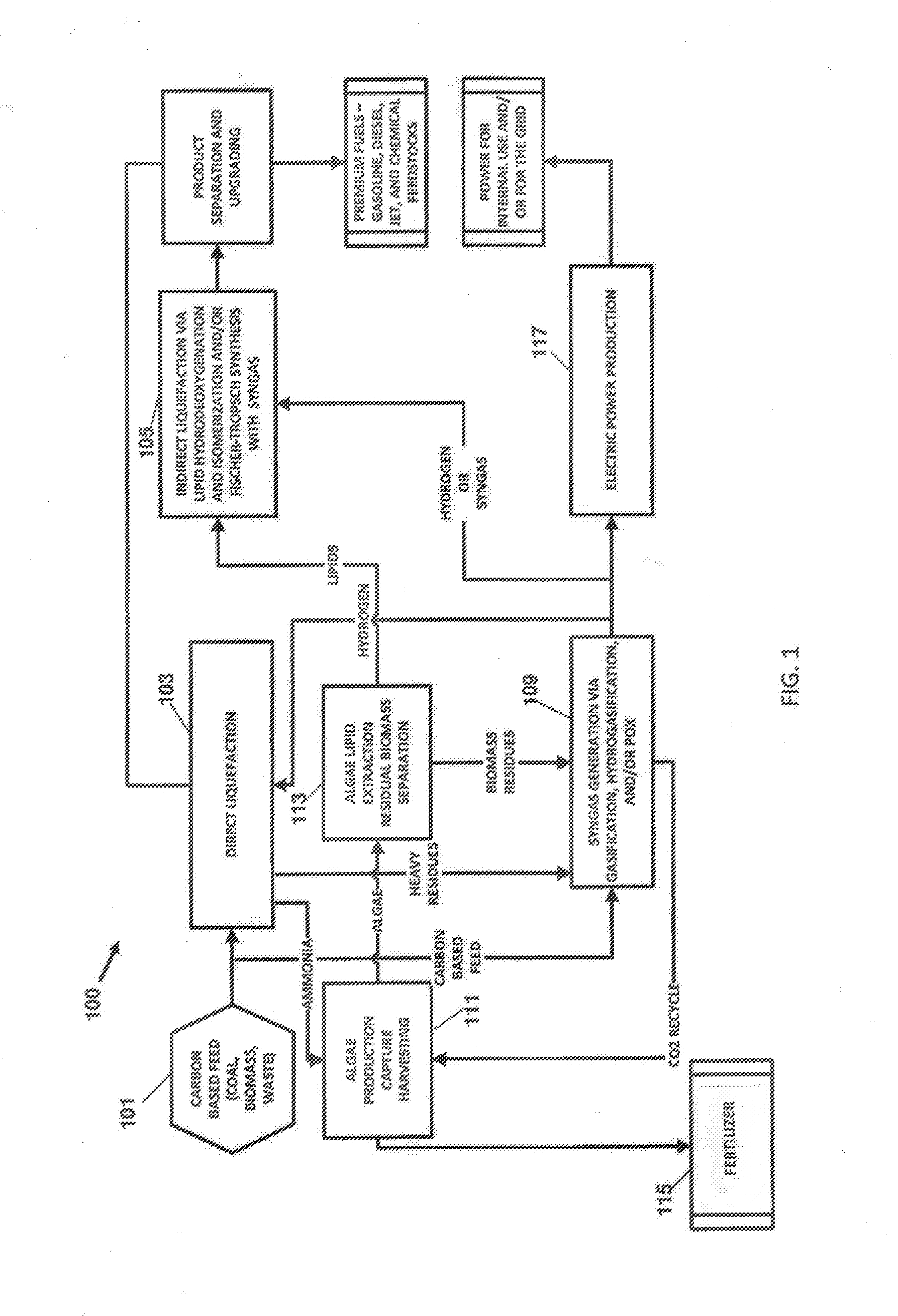

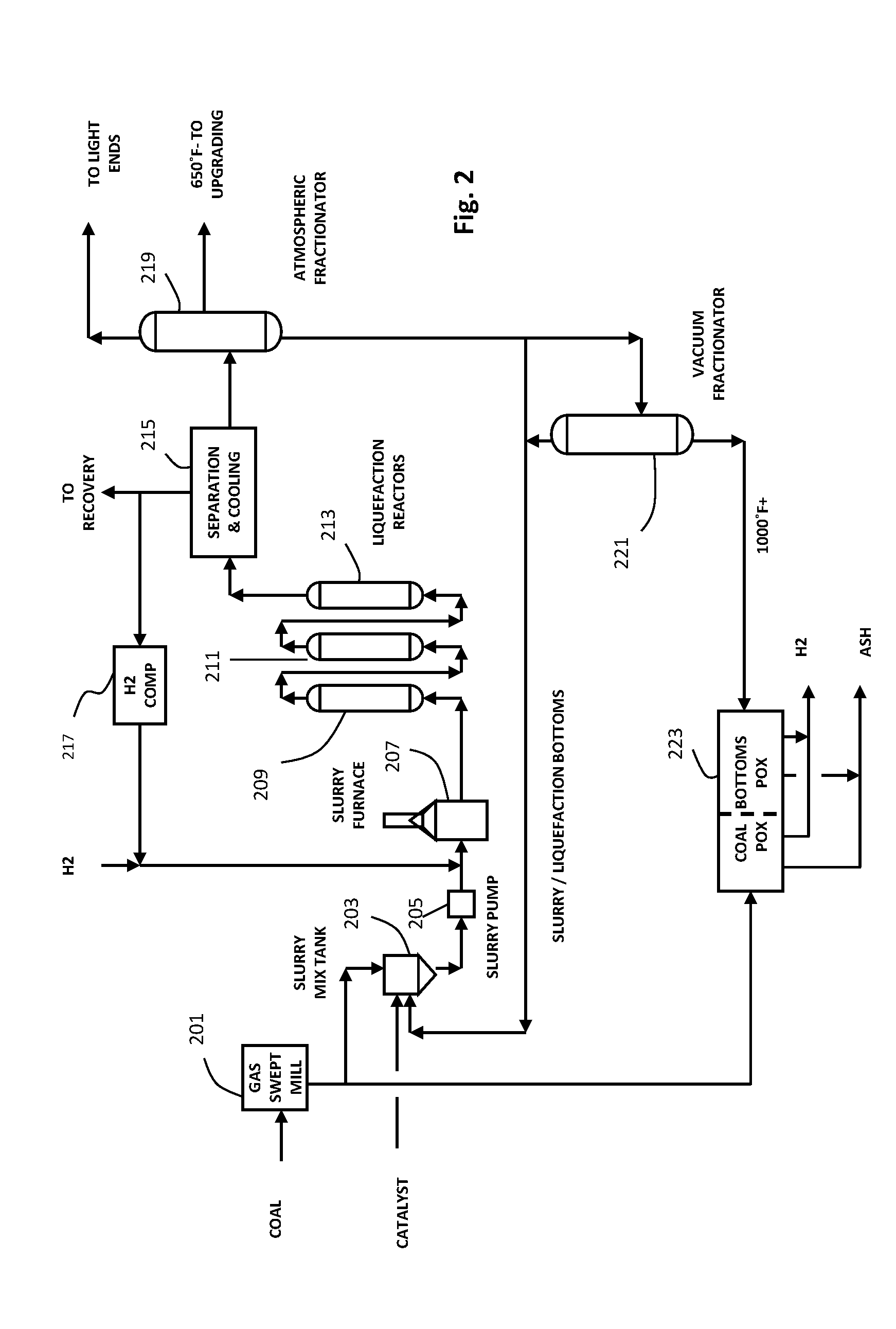

Integrated Coal To Liquids Process And System With Co2 Mitigation Using Algal Biomass

InactiveUS20120144887A1High thermal efficiencyReduced footprintBioreactor/fermenter combinationsBio-organic fraction processingMethane reformerSyngas

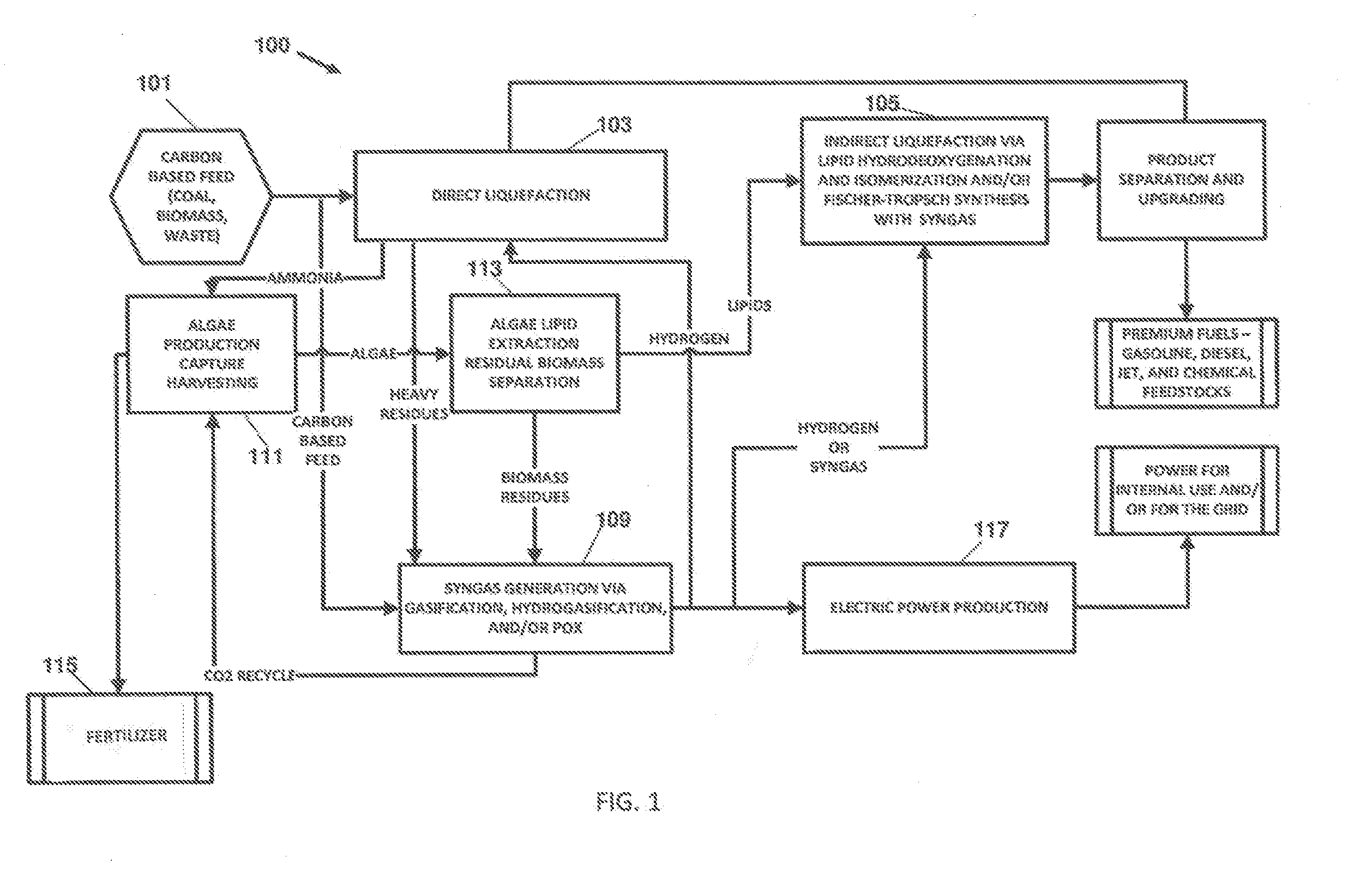

An ICBTL system having a low GHG footprint for converting coal or coal and biomass to liquid fuels in which a carbon-based feed is converted to liquids by direct liquefaction and optionally by indirect liquefaction and the liquids are upgraded to produce premium fuels. CO2 produced by the process is used to produce algal biomass and photosynthetic microorganisms in a photobioreactor. Optionally, lipids extracted from the some or all of the algal biomass is hydroprocessed to produce fuel components and biomass residues and the carbon-based feed our gasified to produce hydrogen and syngas for the direct and indirect liquefaction processes. Some or all of the algal biomass and photosynthetic microorganisms are used to produce a natural biofertilizer. CO2 may also be produced by a steam methane reformer for supplying CO2 to produce the algal biomass and photosynthetic microorganisms.

Owner:ACCELERGY CORP

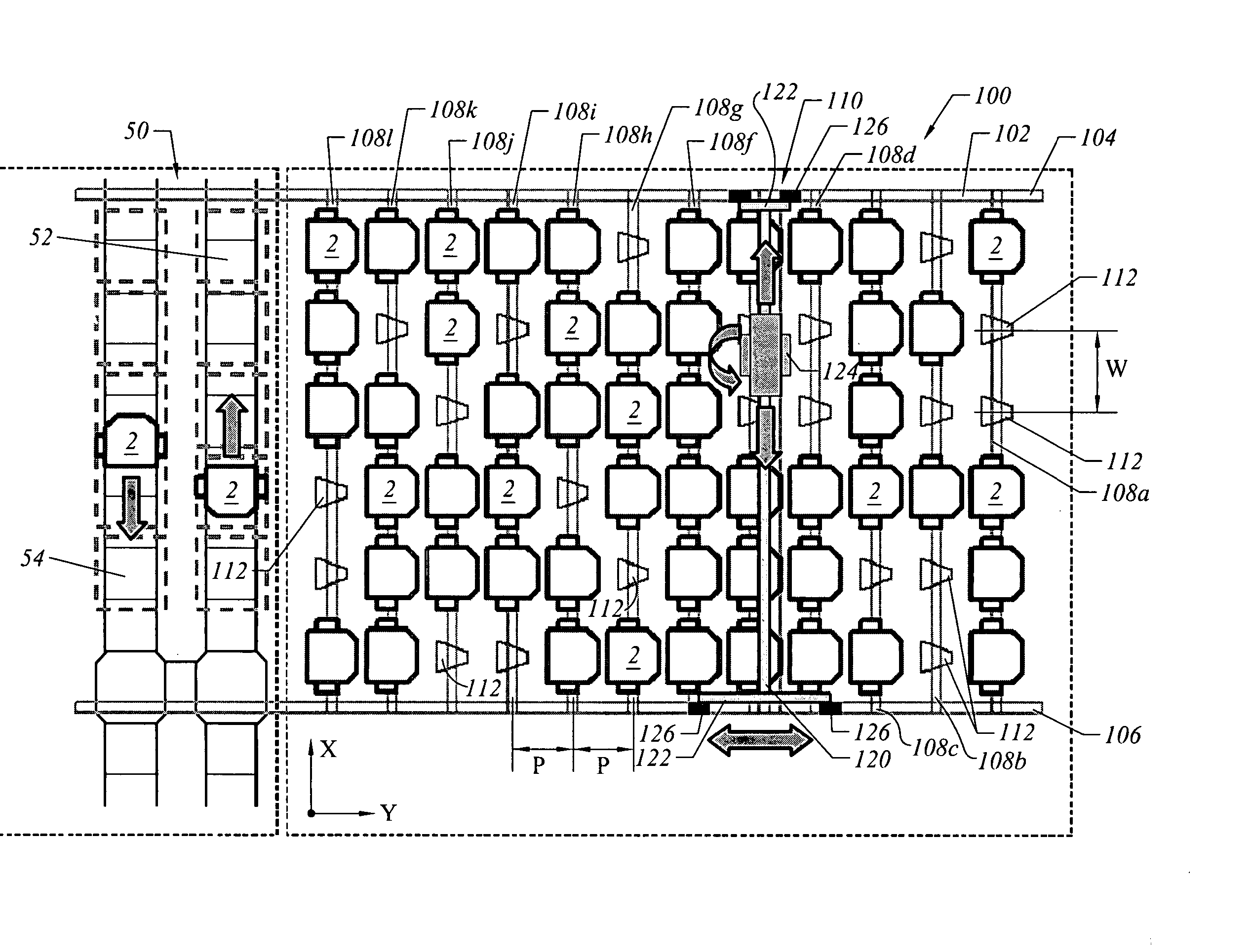

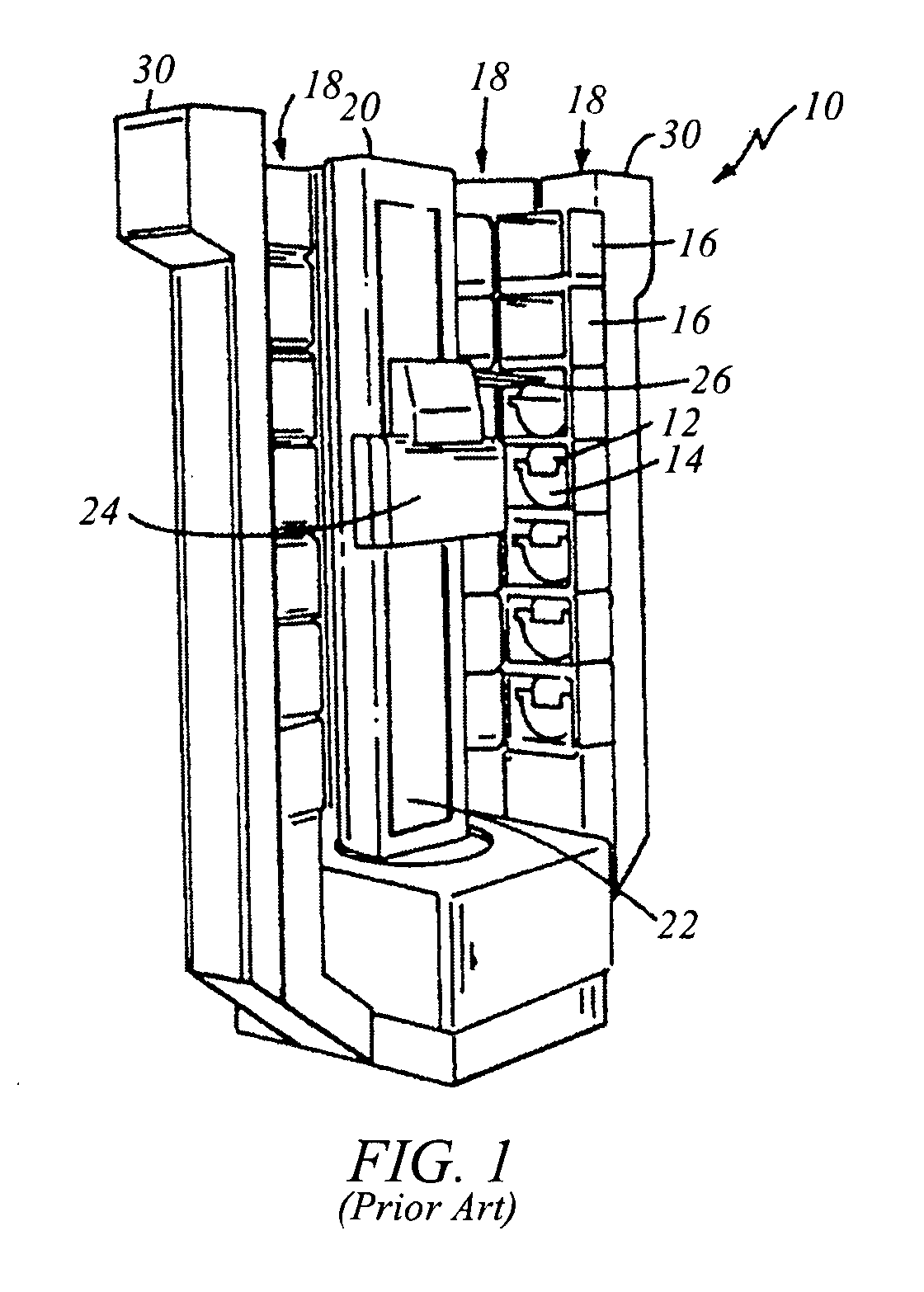

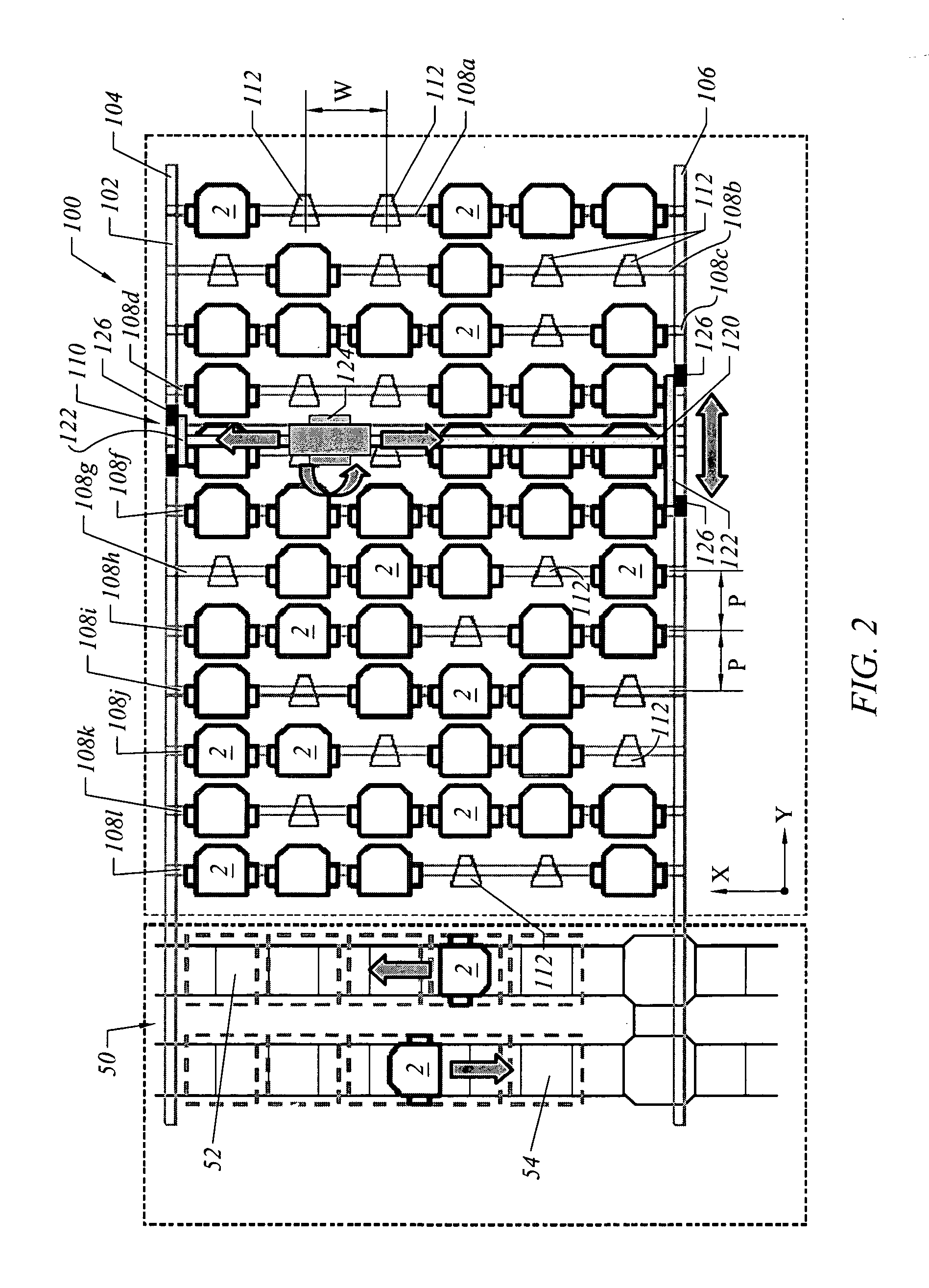

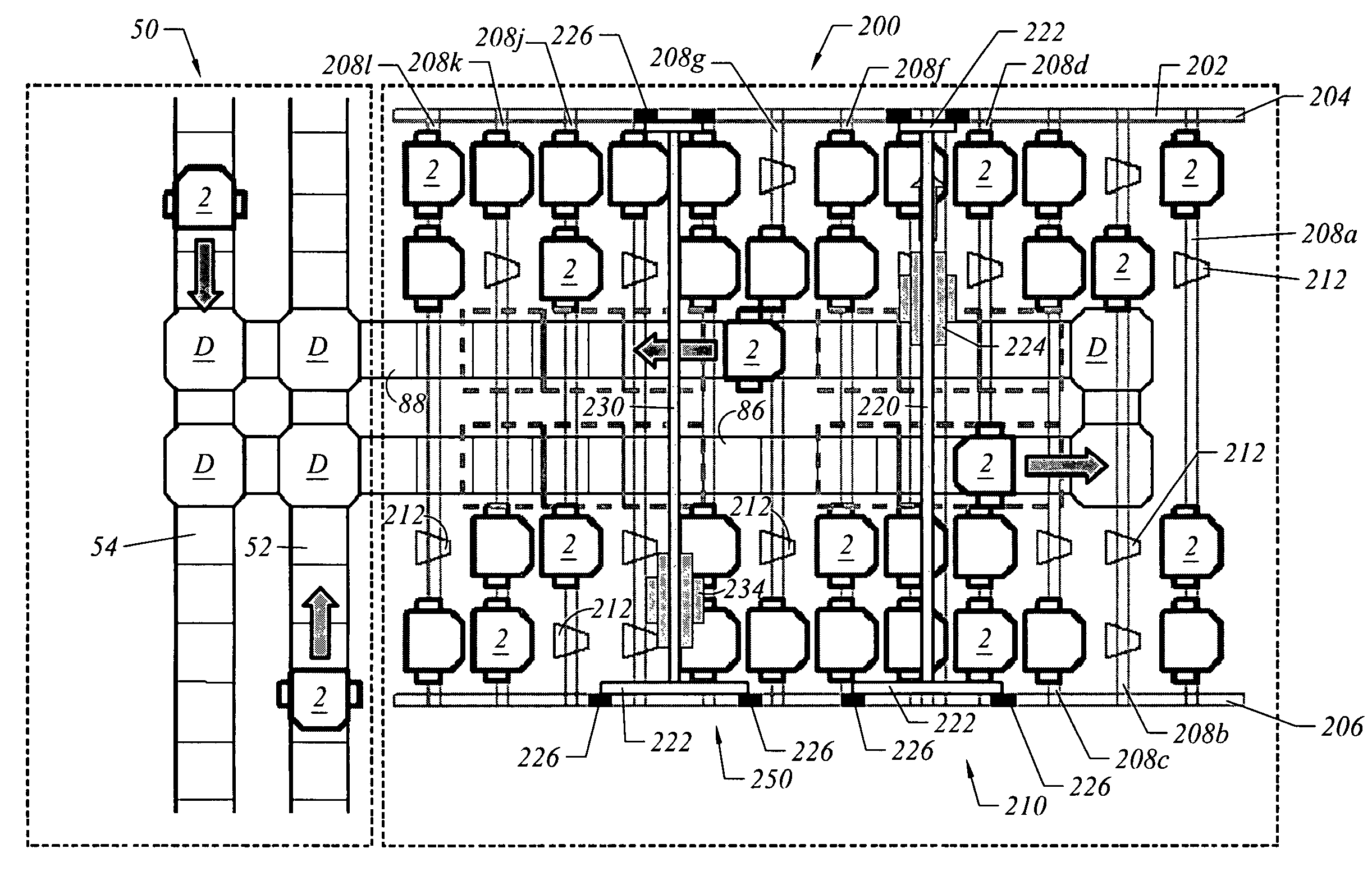

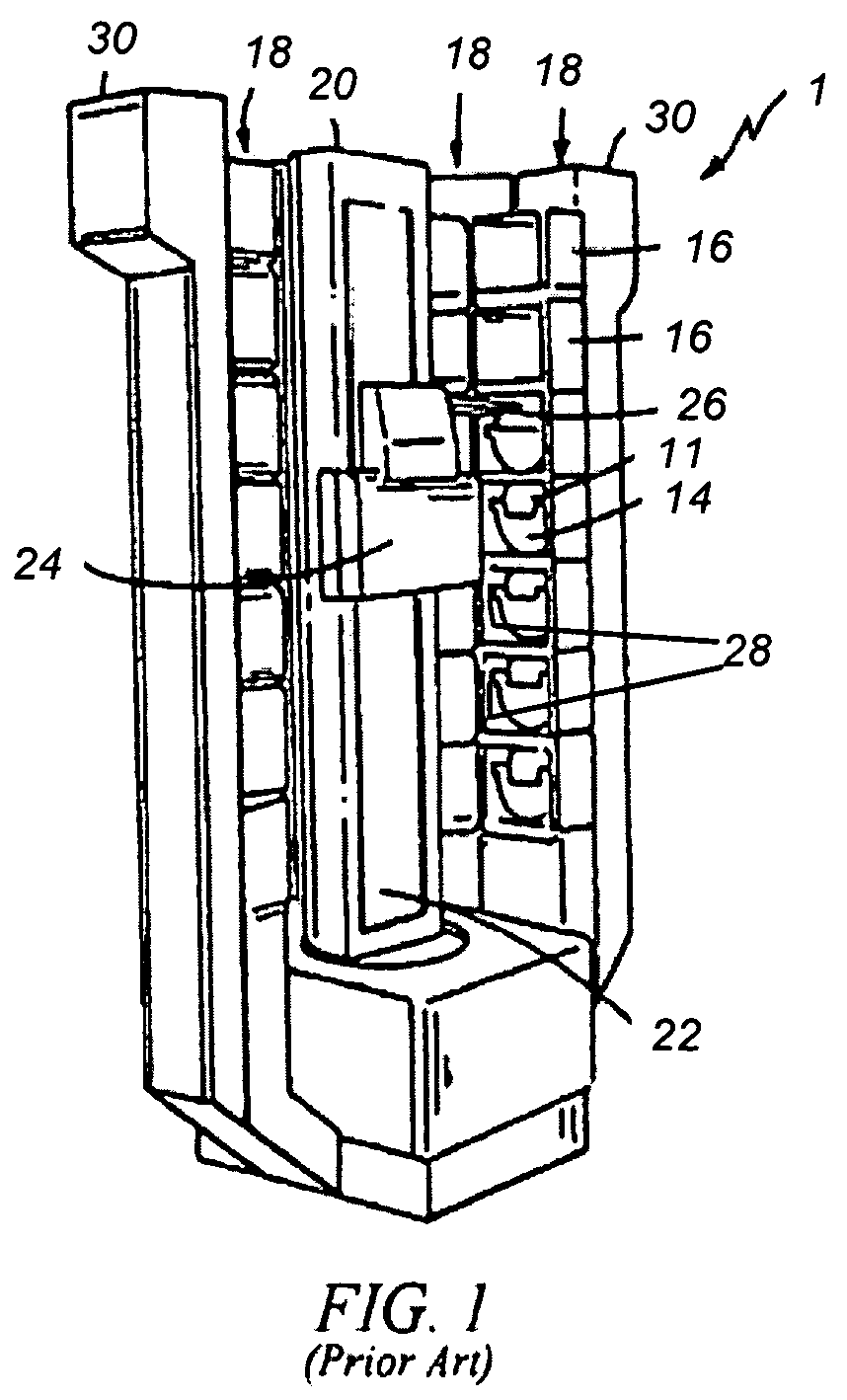

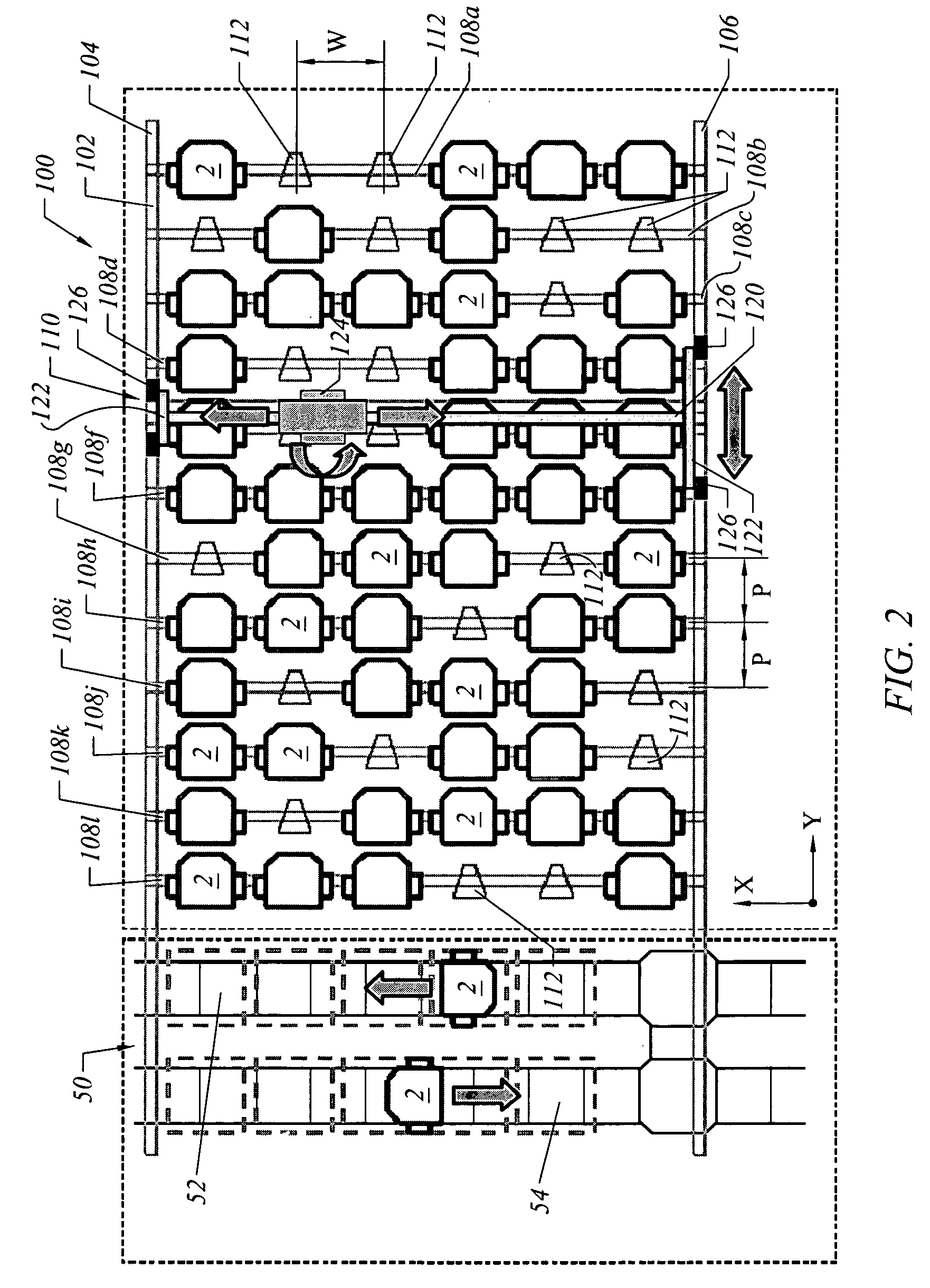

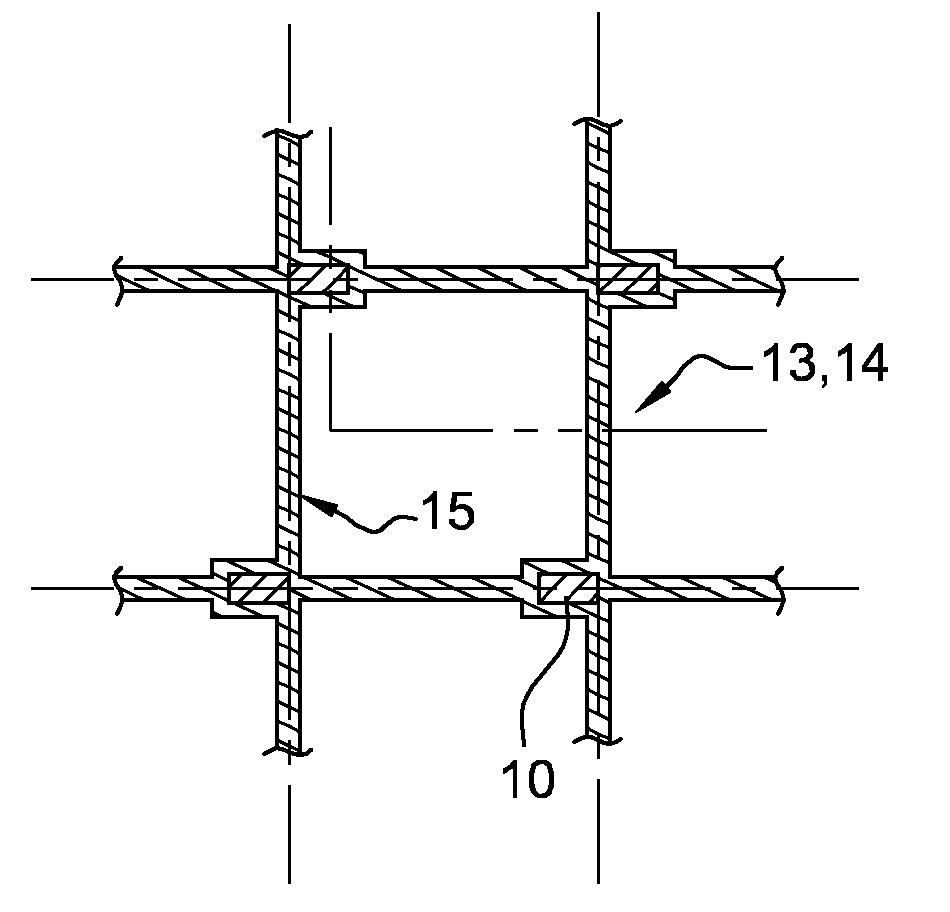

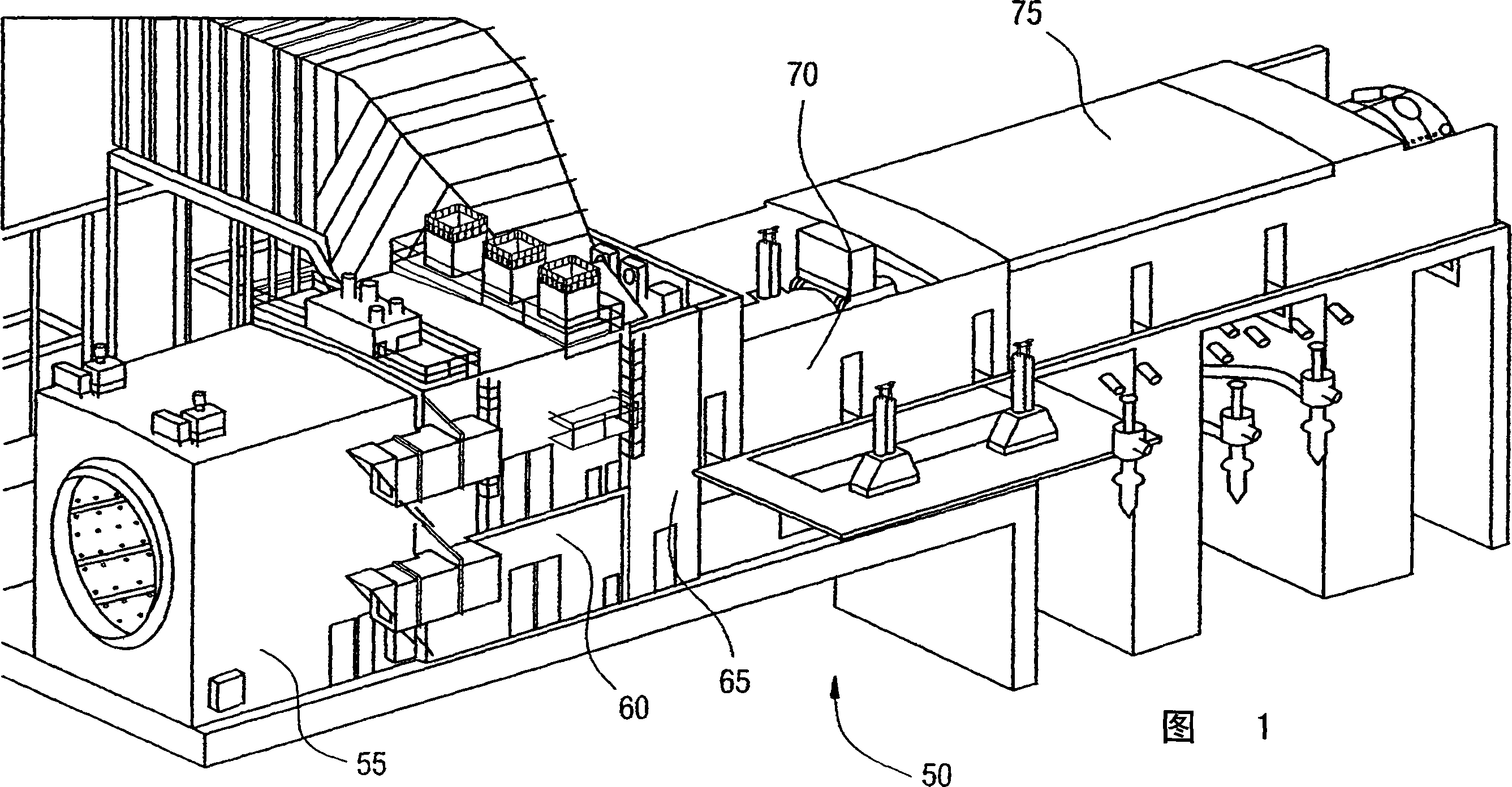

Horizontal array stocker

ActiveUS20070134078A1Reduce and eliminate stocker footprintEliminate footprintSemiconductor/solid-state device manufacturingStorage devicesEngineeringMaterial transport

The present invention comprises a stocker. The stocker comprises multiple container storage locations arranged in a horizontal array. The horizontal array of storage locations may be suspended from the facility ceiling or supported by the facility floor. The stocker may include one or more stocker robots for transporting a workpiece container within the stocker and / or to a material transport system. The stocker may also include features such as container elevators and conveyor loops.

Owner:MURATA MASCH LTD

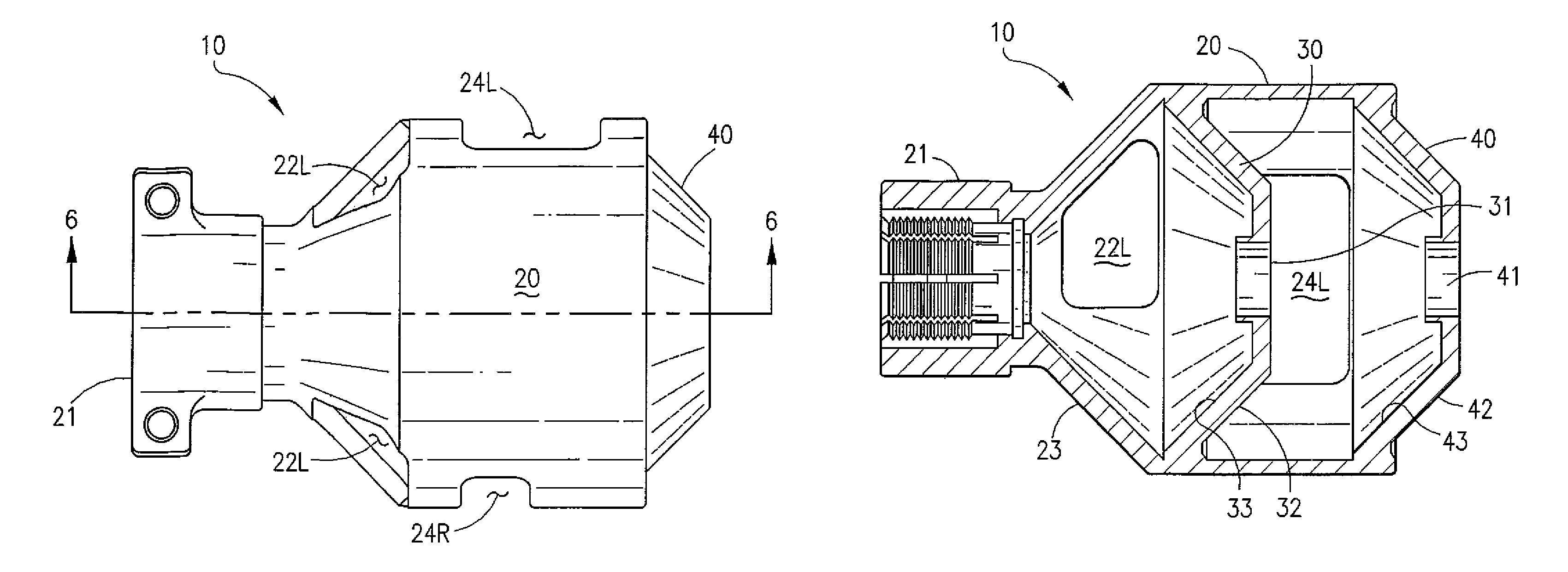

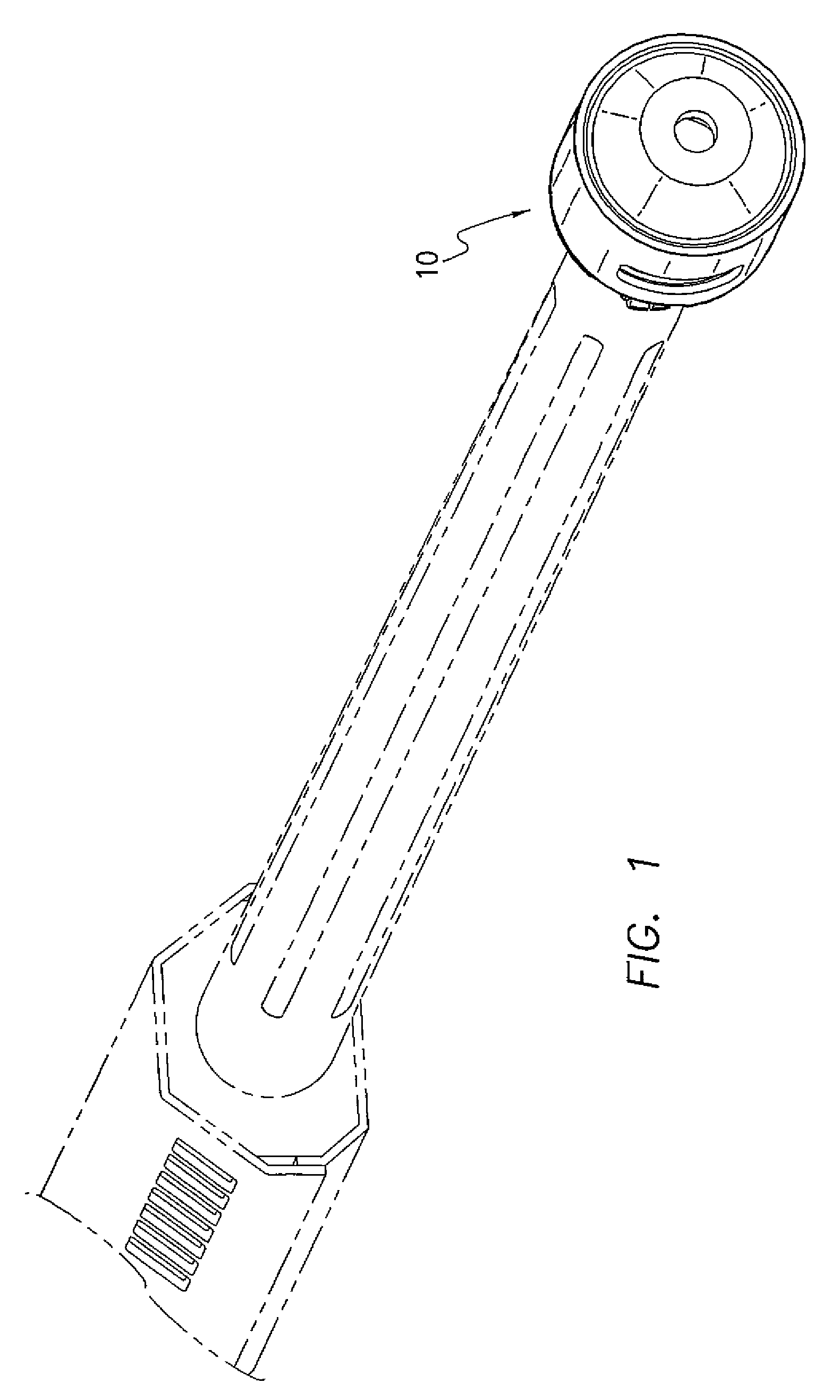

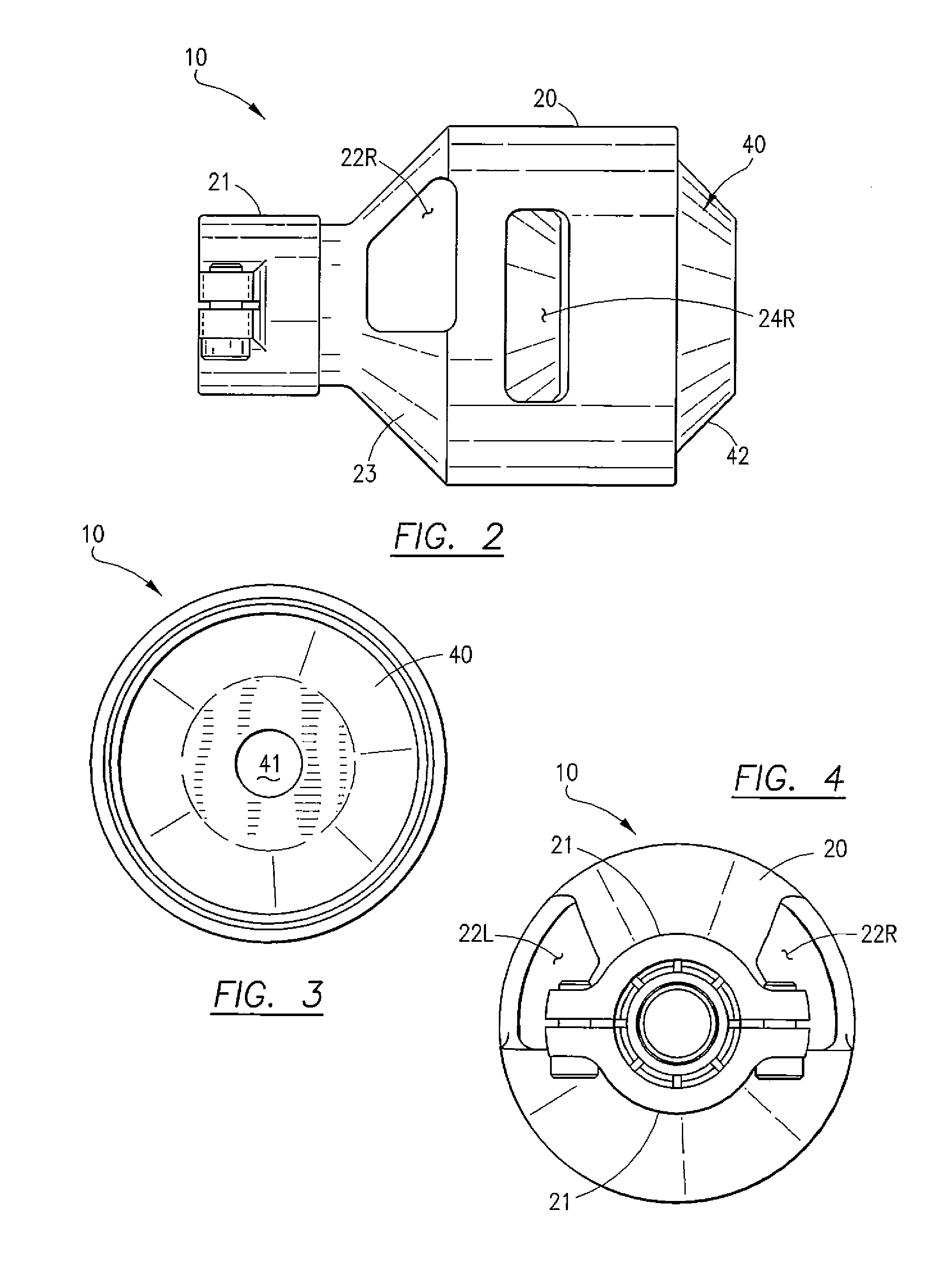

Firearm muzzle brake

InactiveUS7530299B1Reduce recoil forceReadily adaptBreech mechanismsMuzzle attachmentTarget lineStructural component

A muzzle brake includes three primary structural components, namely a main body, a baffle, and an end cap. The components are preferably integrally fabricated into a single piece device, or alternatively may be fabricated separately and assembled. A muzzle brake in accordance with the present invention comprises a generally cylindrical muzzle brake assembly attachable to the muzzle end of a firearm. The muzzle brake assembly forms two expansion chambers, each of which is bounded by a peripheral sidewall defining opposing left and right vent apertures and a converging end wall. The end walls define axially aligned openings sized slightly larger than the diameter of the projectile for allowing the projectile to pass from the firearm muzzle, through the muzzle brake, and onward down the target line toward the intended target. The first chamber defines opposing left and right vent apertures for venting gases generally upward and rearward to reduce muzzle jump. The second chamber defines opposing left and right side apertures, with the left aperture being substantially larger than the right aperture for venting gases to counter torque related movement.

Owner:POFF CHARLES

Horizontal array stocker

ActiveUS7780392B2Eliminate footprintReduce complexitySemiconductor/solid-state device manufacturingLoading/unloadingEngineeringMaterial transport

The present invention comprises a stocker. The stocker comprises multiple container storage locations arranged in a horizontal array. The horizontal array of storage locations may be suspended from the facility ceiling or supported by the facility floor. The stocker may include one or more stocker robots for transporting a workpiece container within the stocker and / or to a material transport system. The stocker may also include features such as container elevators and conveyor loops.

Owner:MURATA MASCH LTD

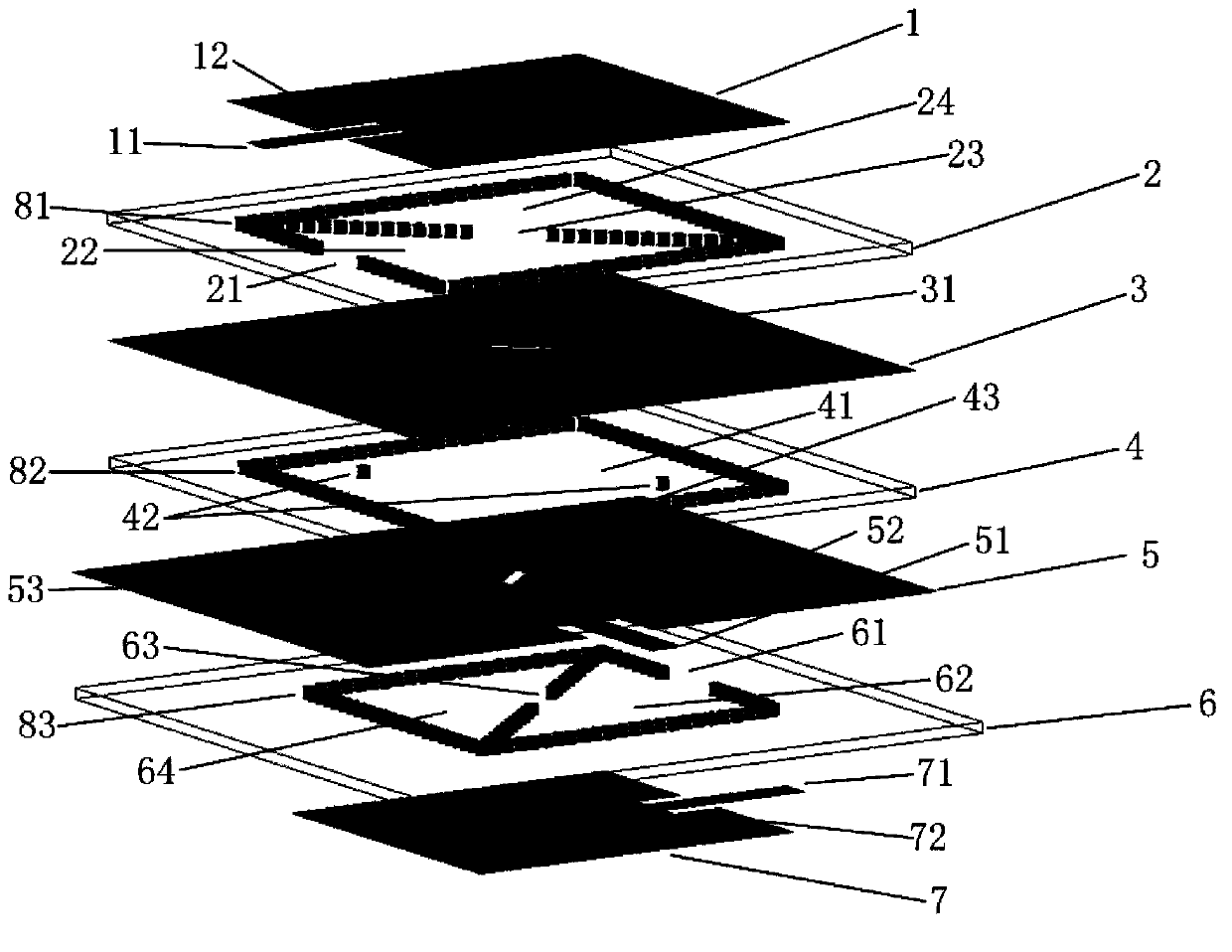

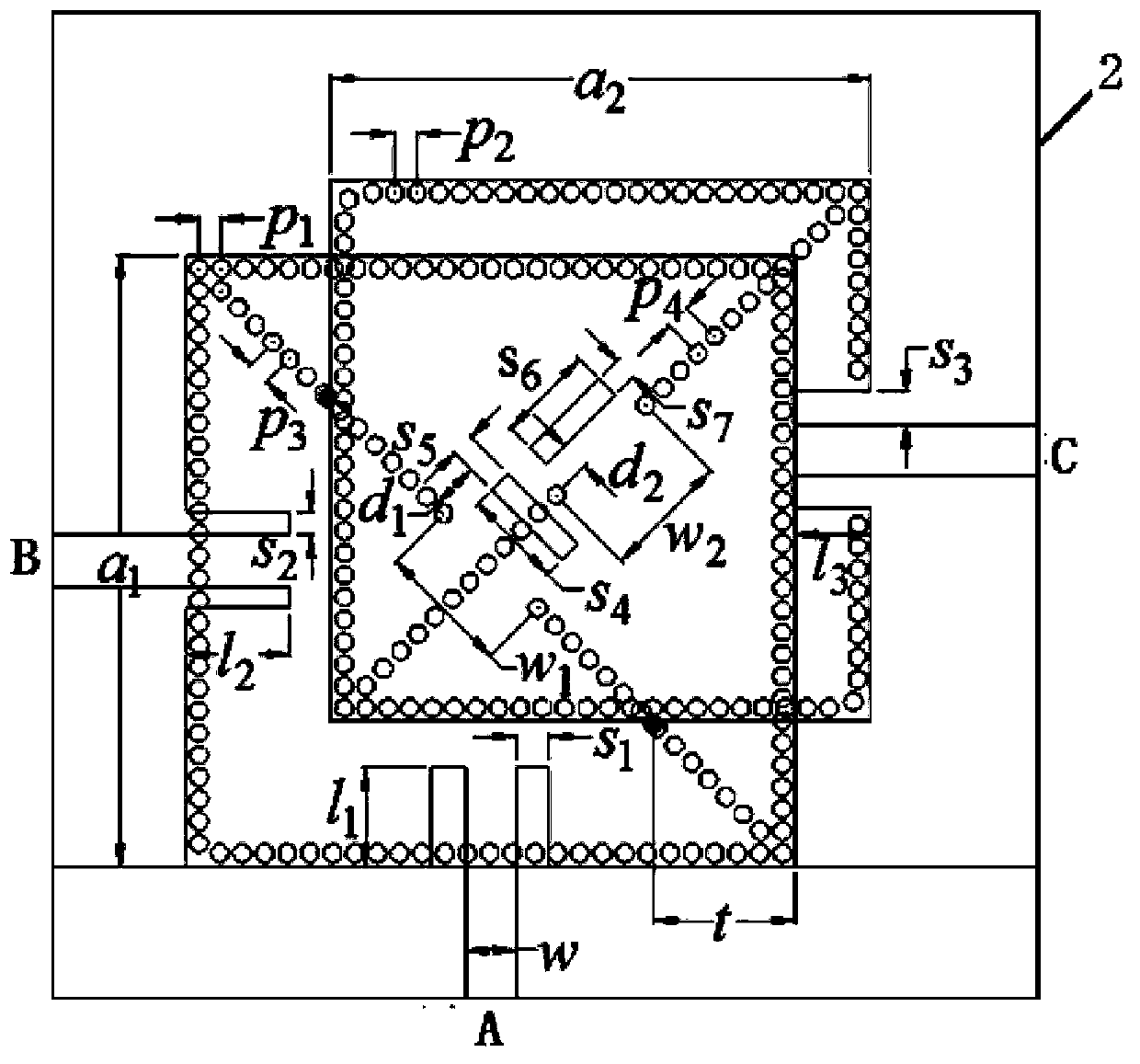

Miniaturized substrate integration waveguide duplexer

ActiveCN103390784AEliminate footprintSmall sizeWaveguide type devicesMillimeter wave communication systemsResonant cavity

The invention discloses a miniaturized substrate integration waveguide duplexer which comprises a first metal copper coating layer, a first dielectric layer, a second metal copper coating layer, a second dielectric layer, a third metal copper coating layer, a third dielectric layer and a fourth metal copper coating layer which are stacked from the top down sequentially, wherein a dual-mode resonant cavity and triangular resonant cavities are defined by metallized through hole arrays; the dual-mode resonant cavity is connected with the triangular resonant cavities by coupling slots; the triangular resonant cavities are connected mutually by coupling windows; and a microstrip line structure is used for input and output. The duplexer can be used for microwave and millimeter wave communication systems, and has the advantages that the duplexer is suitable for system miniaturization, and is light in weight, low in cost, easy to integrate and fast in processing cycle.

Owner:JIANGSU HENGXIN TECH CO LTD

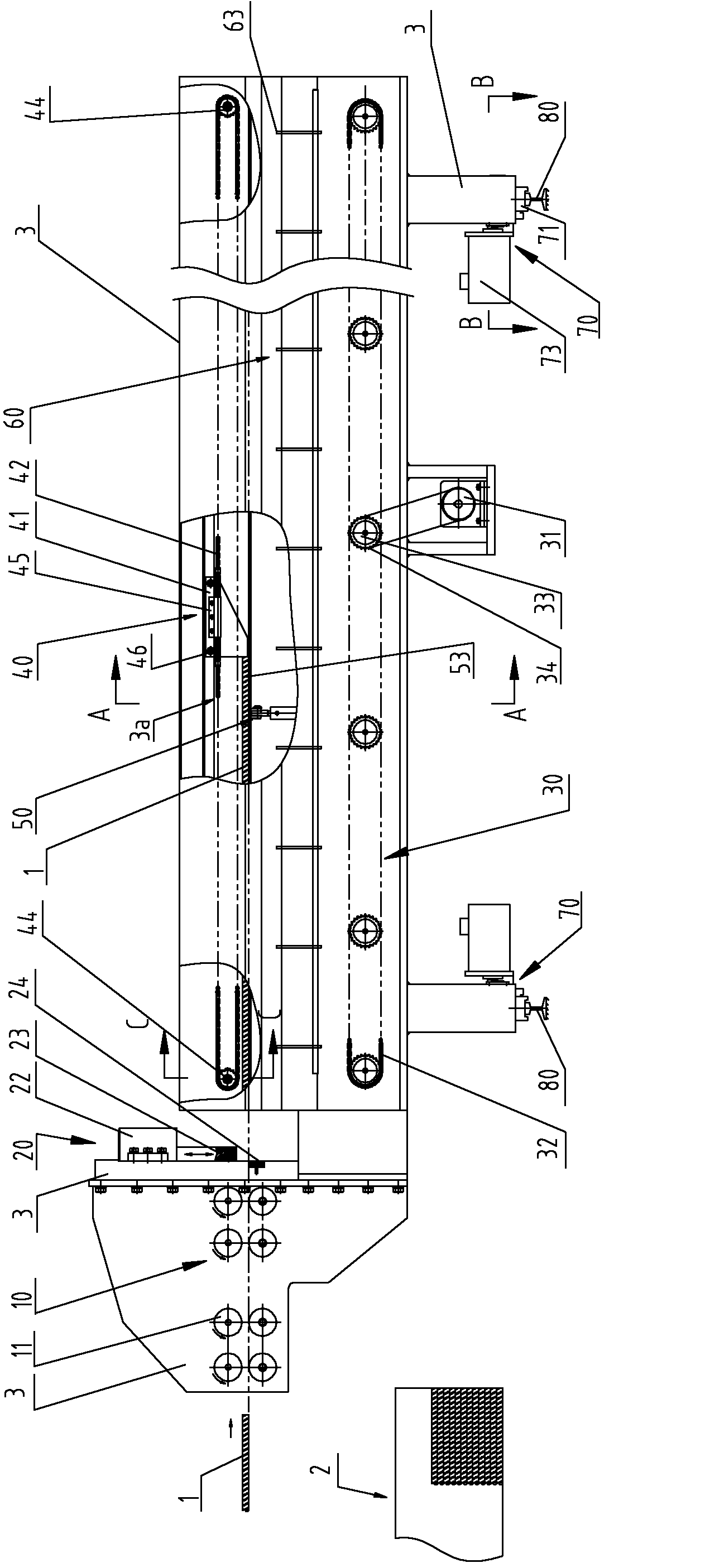

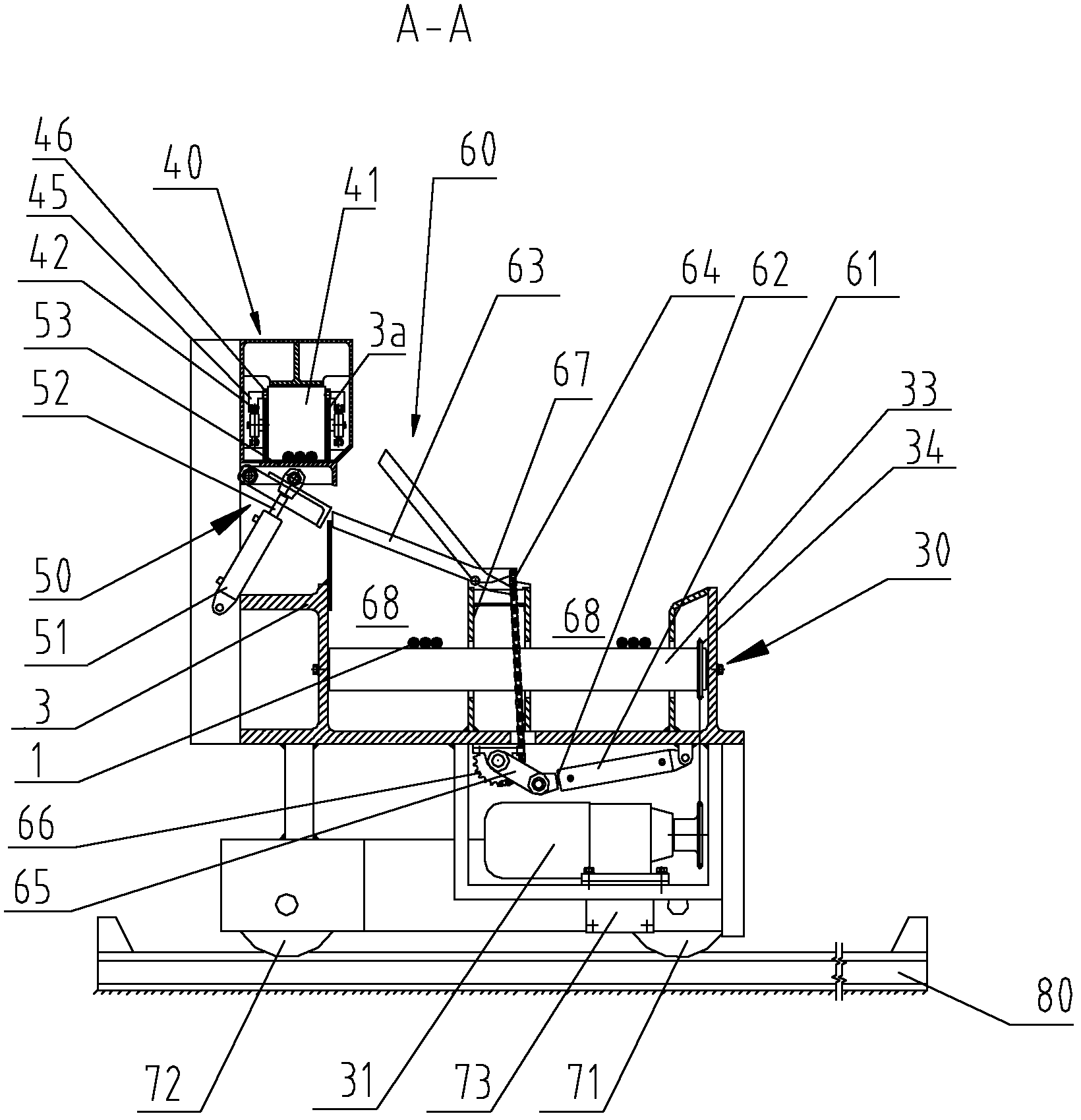

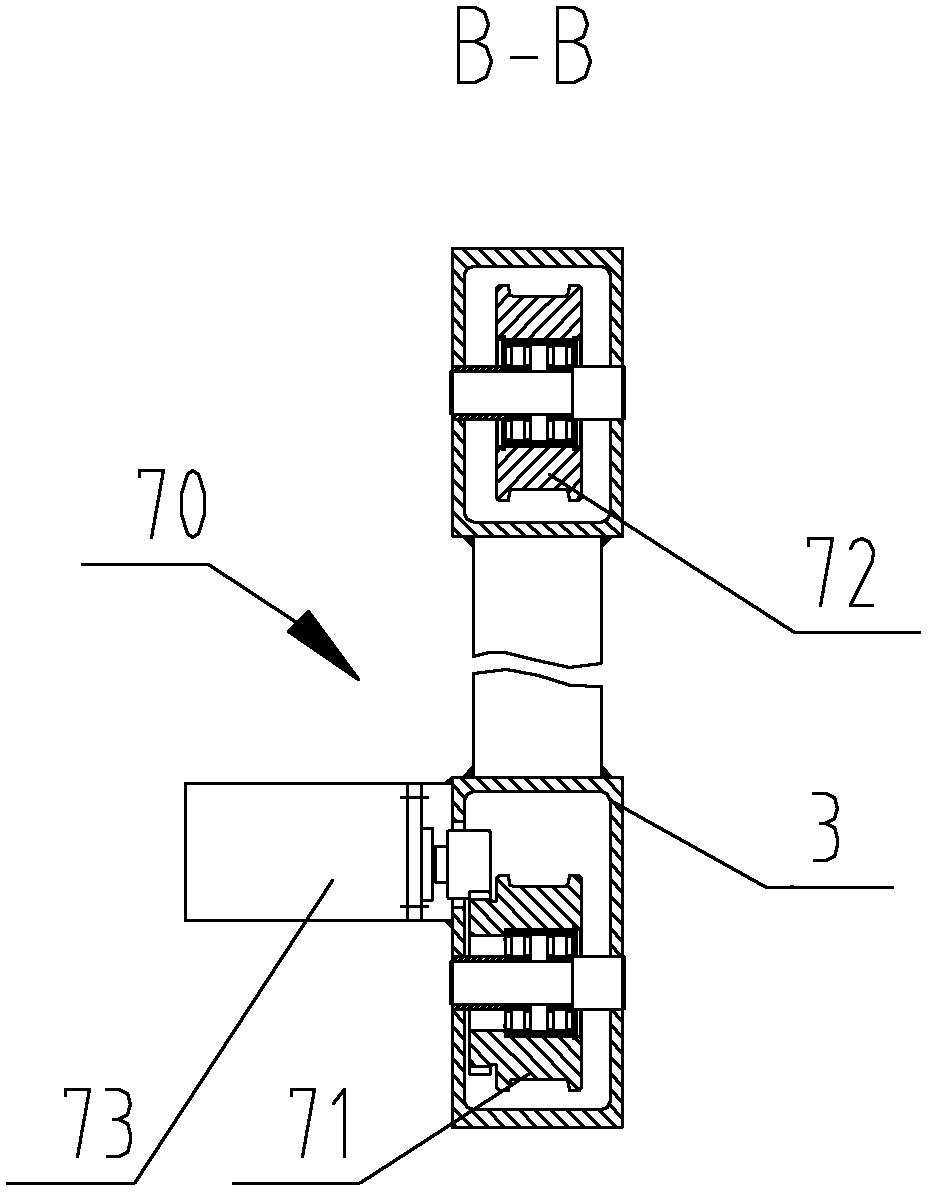

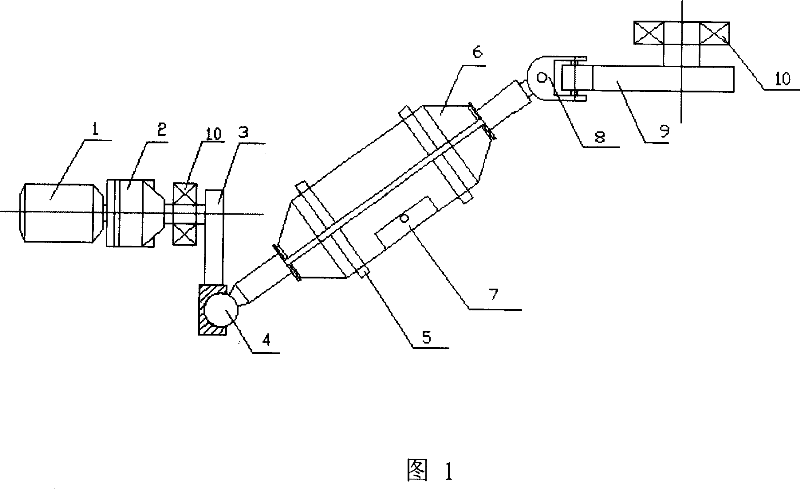

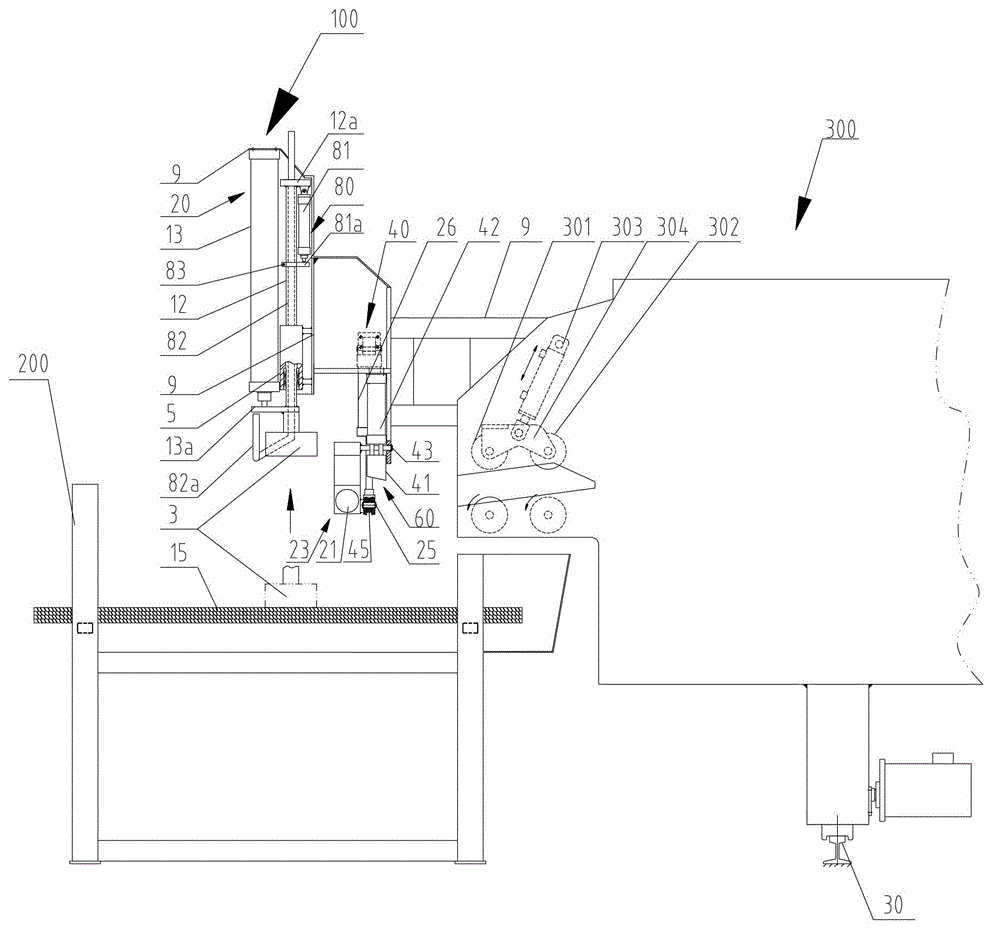

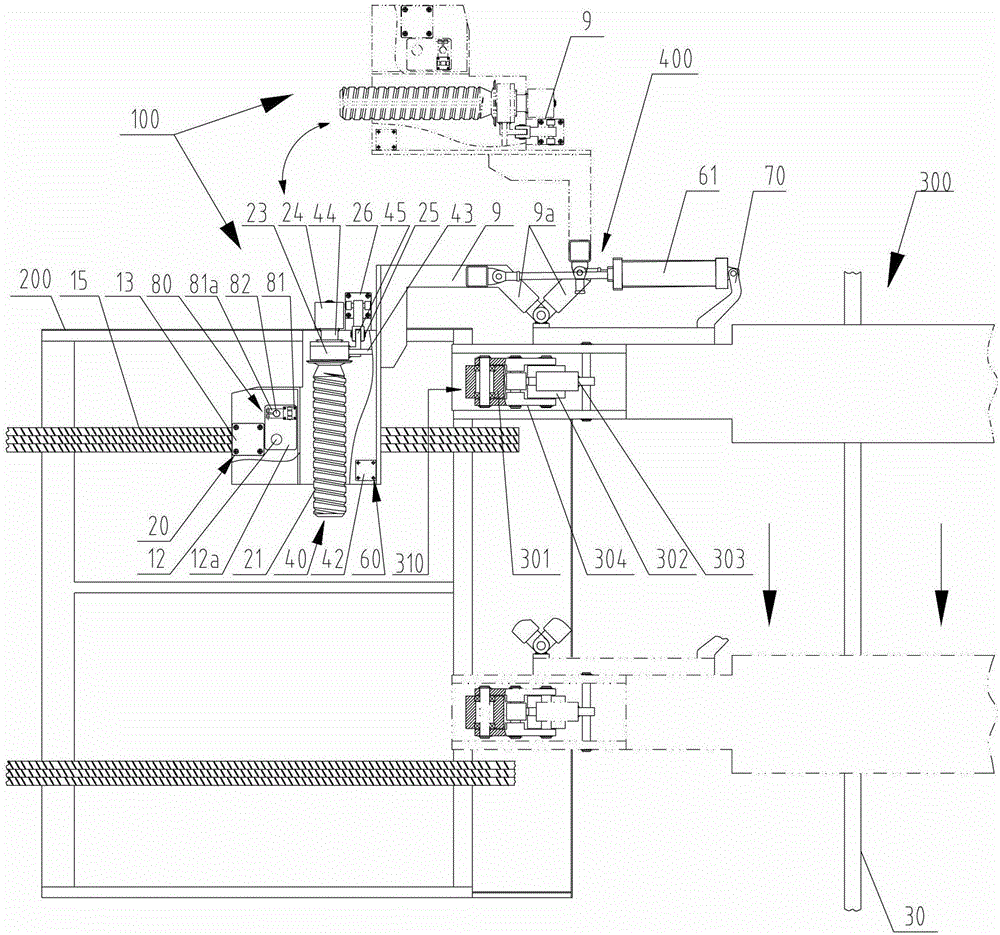

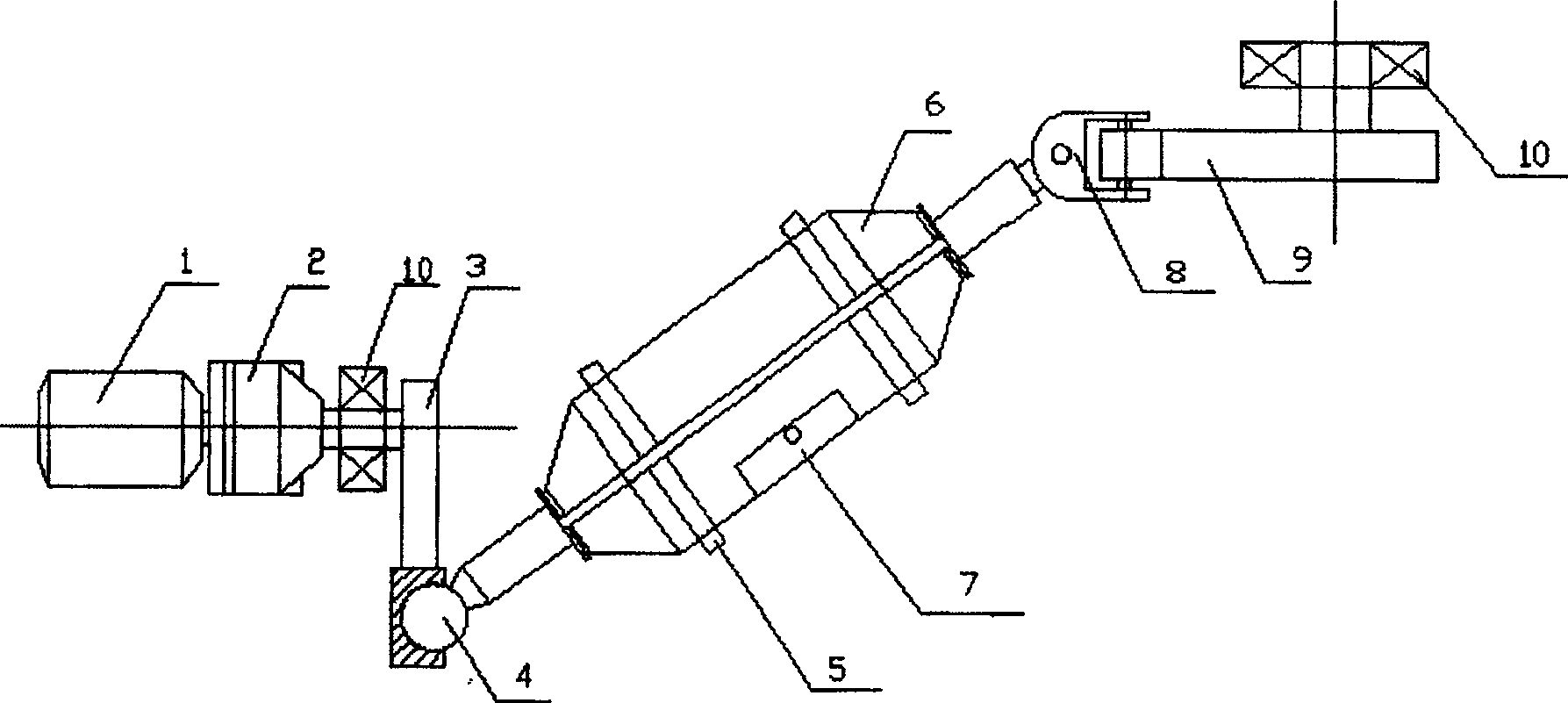

Movable automatic steel bar shearing-collecting device

The invention discloses a movable automatic steel bar shearing-collecting device. The movable automatic steel bar shearing-collecting device comprises a track and a movable rack moving along the track and is characterized in that a steel bar importing mechanism, a steel bar shearing mechanism and a steel bar conveying-sizing mechanism are arranged on the movable rack along the steel bar input axis direction in sequence; and a steel bar collecting device is arranged below the steel bar conveying-sizing mechanism. The movable automatic steel bar shearing-collecting device has the beneficial effects of being movably arranged nearby storage areas of different specifications of steel bars, completing the all work procedures including importing, cutting to length, unloading, overturning and exporting of the steel bar, saving the transporting procedures and transporting tools for equipment away from the automatic steel bar shearing-collecting device by a certain distance in the prior art, and eliminating the space occupied by the original procedures and a plurality of intermediate links. The movable automatic steel bar shearing-collecting device has the advantages of simple and compact structure, easy operation, high efficiency, labor saving and time saving, convenience for maintenance, energy conservation, environment friendliness, and low failure rate.

Owner:TJK MACHINERY TIANJIN

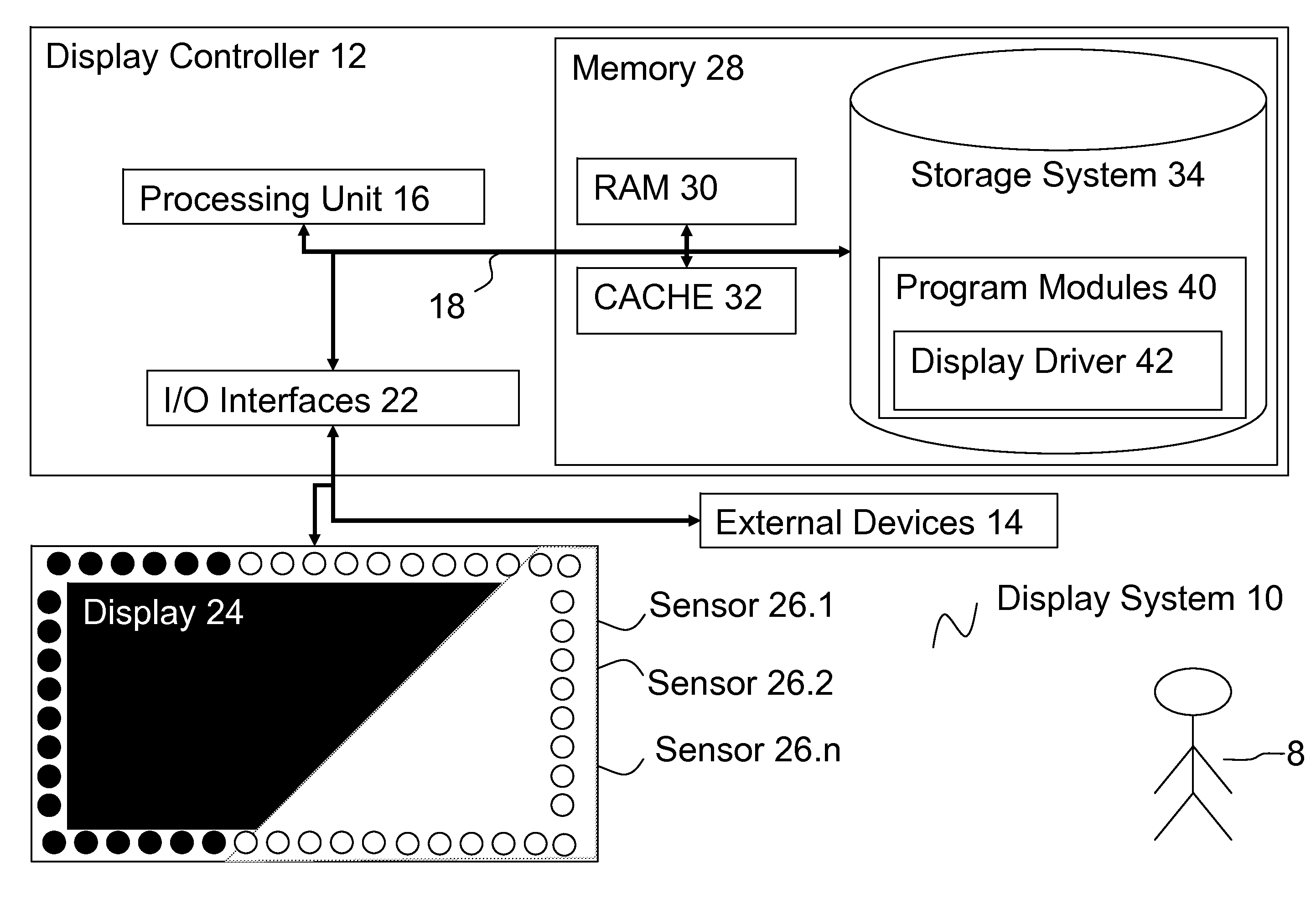

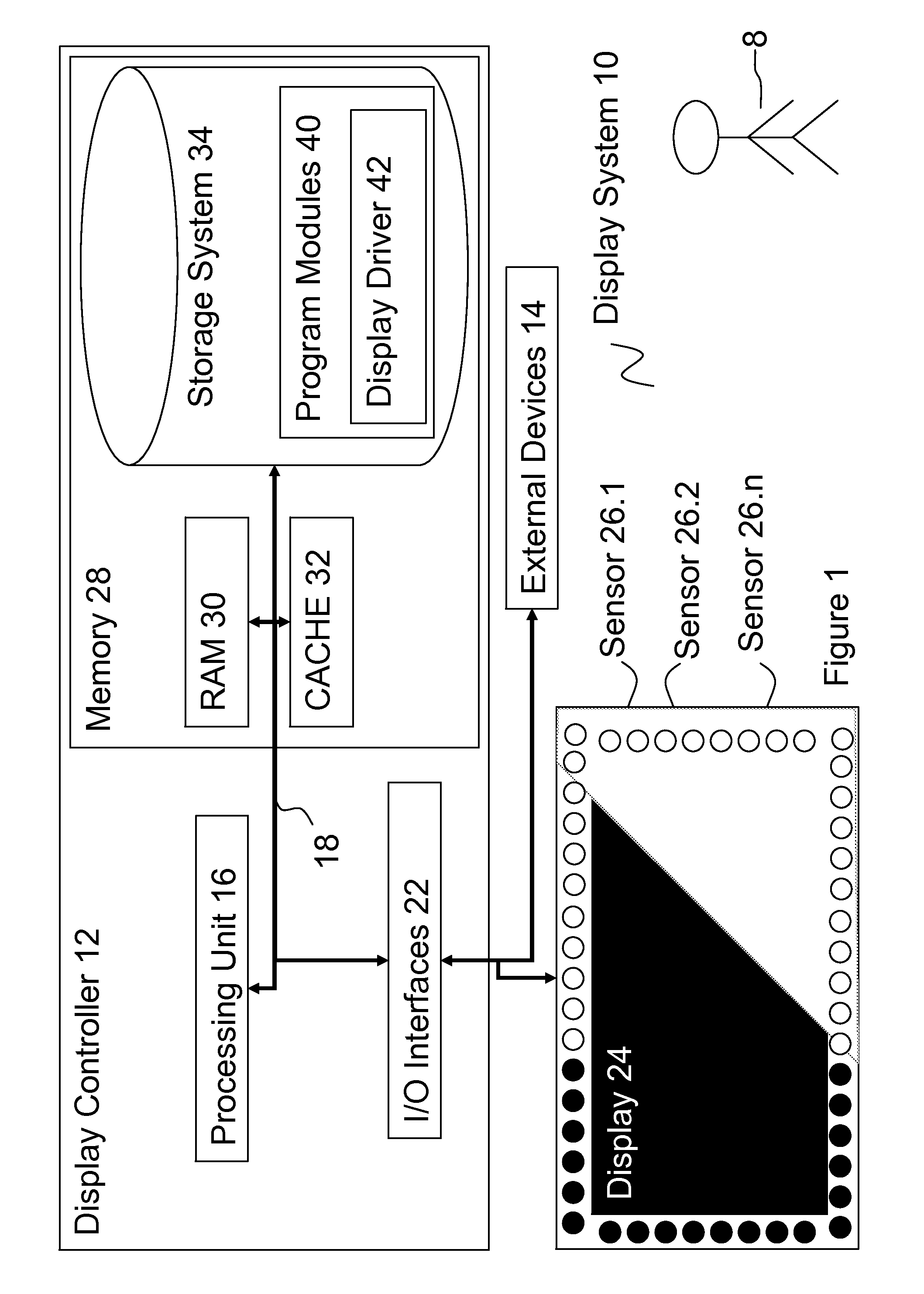

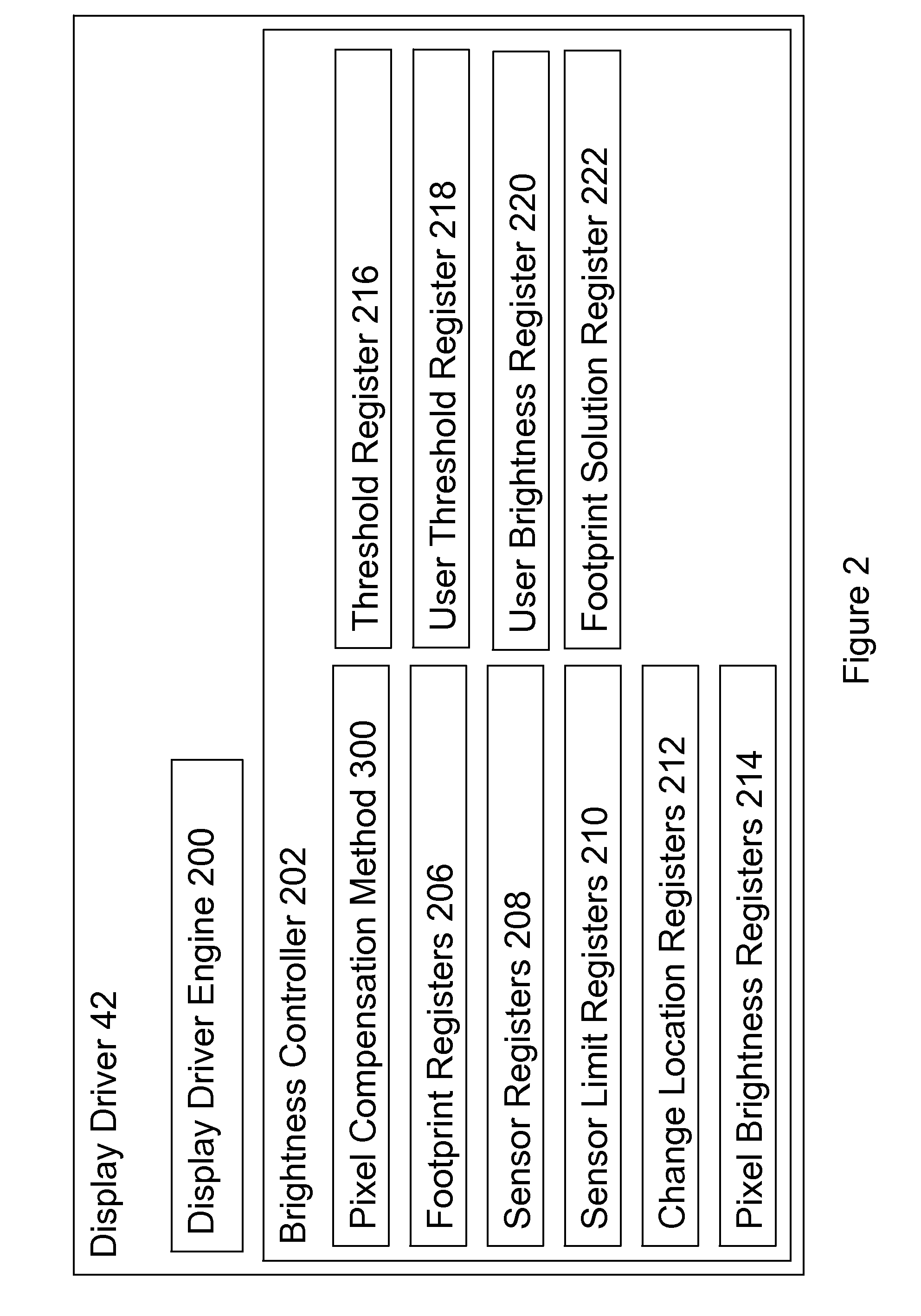

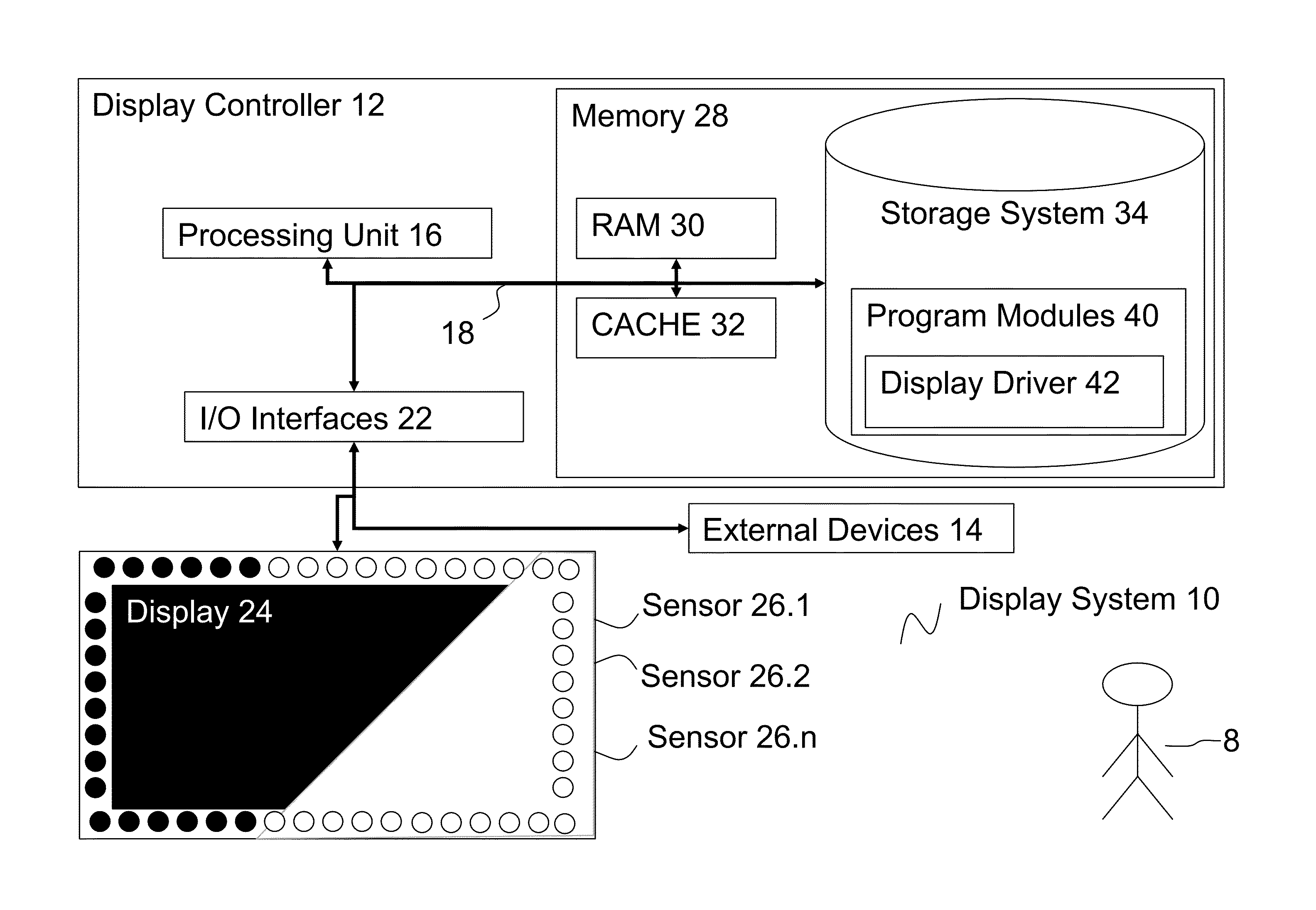

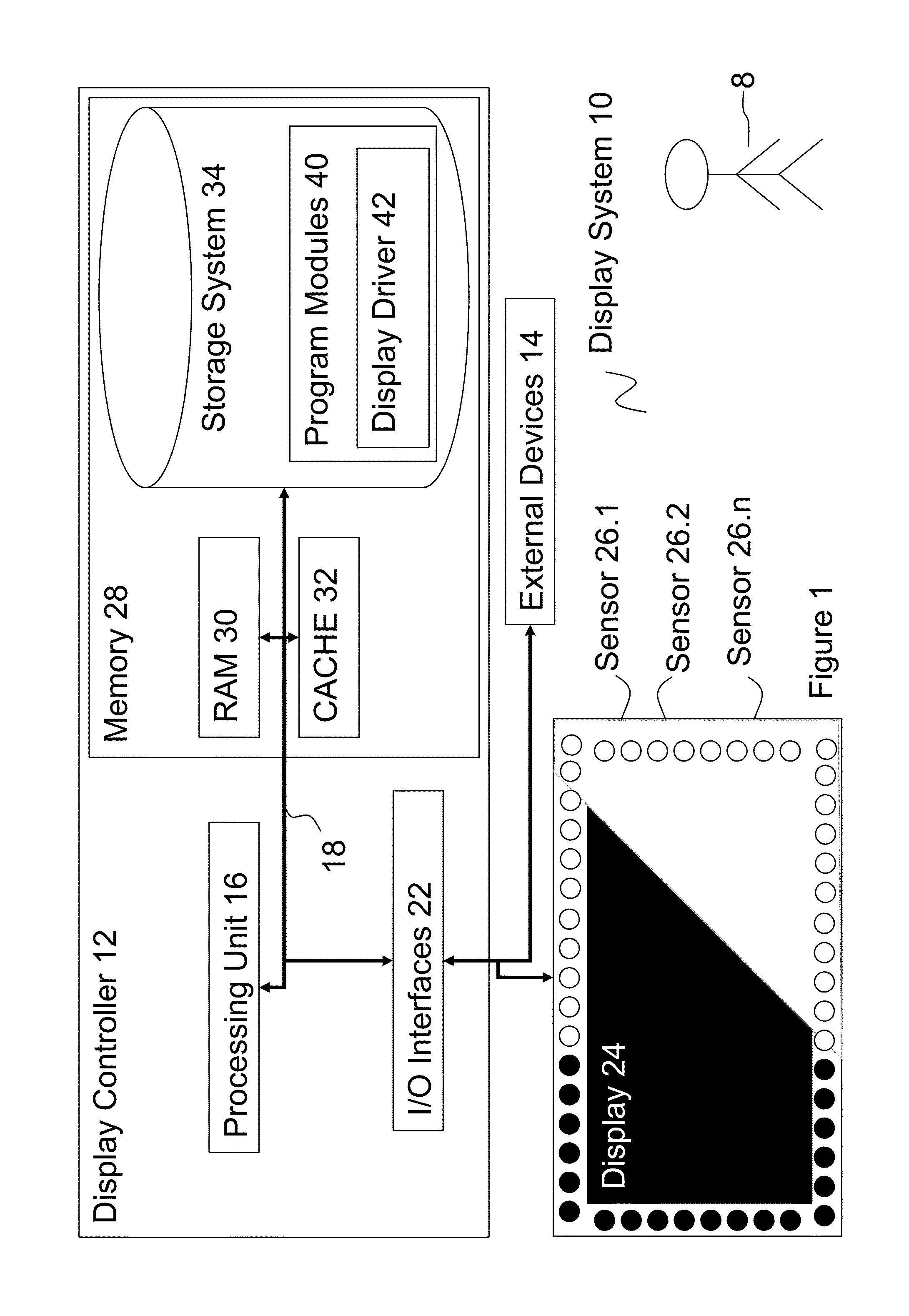

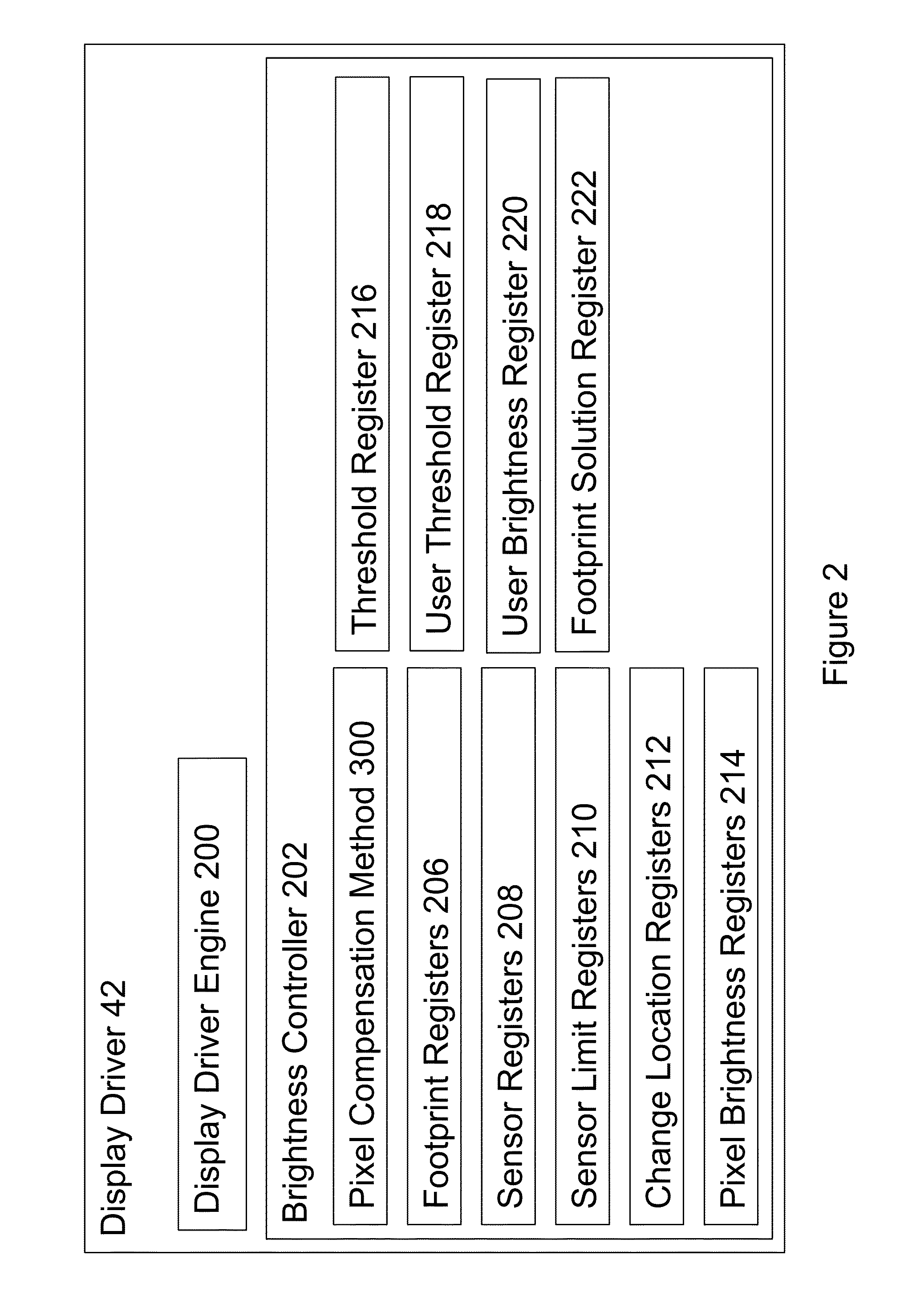

Display Brightness Adjustment

ActiveUS20130321369A1Promote resultsLow costCathode-ray tube indicatorsInput/output processes for data processingSensor arrayDisplay device

A display comprising an array of pixels having individually adjustable brightness levels; an array of light sensors fixed relative to the pixel array; and a brightness controller for estimating a glare footprint on the pixel array from light level data provided by the sensor array and for adjusting the relative brightness levels of pixels that fall in the estimated glare footprint.

Owner:IBM CORP

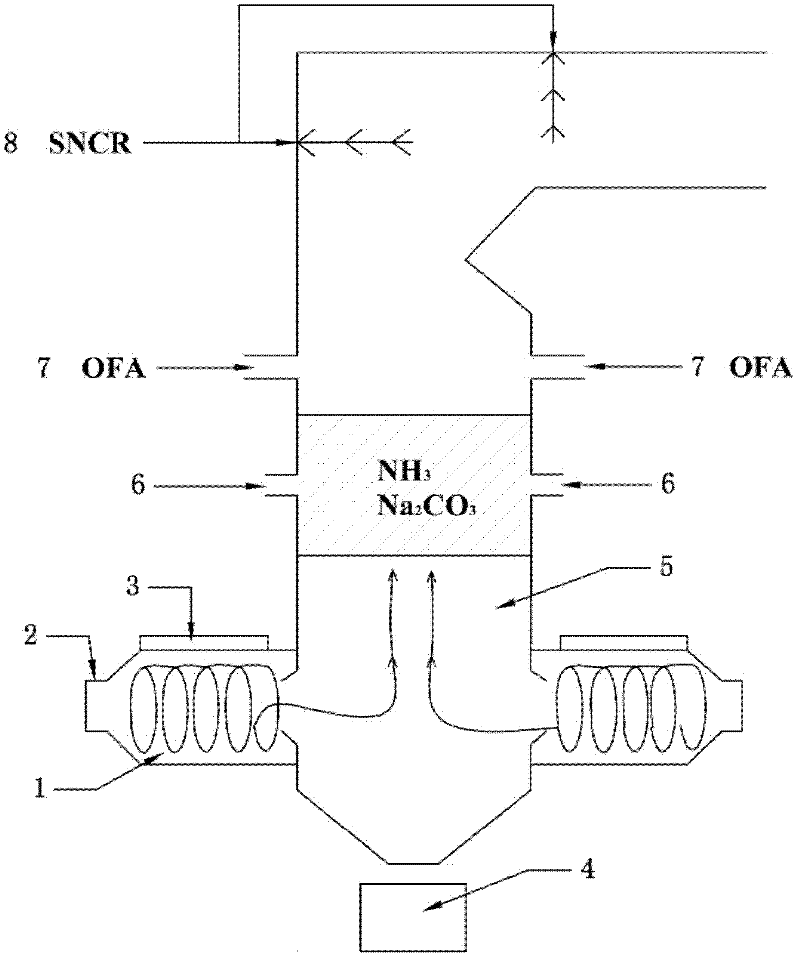

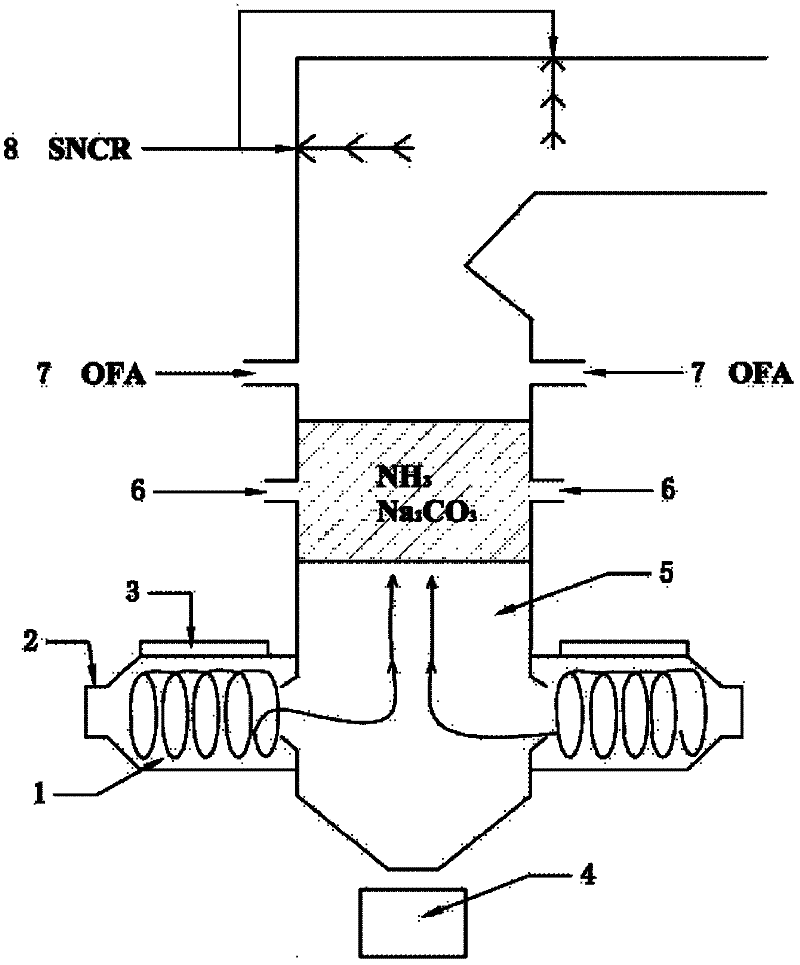

A cyclone combustion boiler advanced air staged combustion denitrification system and method

InactiveCN102287812ALow costImprove denitrification efficiencyFluidized bed combustionNon-combustible gases/liquids supplyCombustion systemCyclone

The invention discloses an advanced air staged combustion denitrification system and method for a cyclone combustion boiler. In view of the high emission of NOx pollutants in the cyclone combustion boiler itself, and the current key technologies, raw materials, and instruments for SCR flue gas denitrification in my country still need to be imported, and the technology itself requires expensive catalysts, and there is catalyst poisoning, replacement, and additional devices Unfavorable factors such as taking up space and taking up space lead to high operating costs, which greatly restricts its application. For this reason, the present invention proposes a cyclone combustion boiler advanced air staged combustion denitrification method and system, the denitrification efficiency is expected to be as high as 95%, not only can greatly reduce the NOx emission of the cyclone combustion boiler, but also compared with the SCR technology, eliminating the need for The use of expensive catalysts and the space occupied by flue gas denitrification devices have the advantages of low cost, simple equipment, and easy implementation of transformation.

Owner:XI AN JIAOTONG UNIV

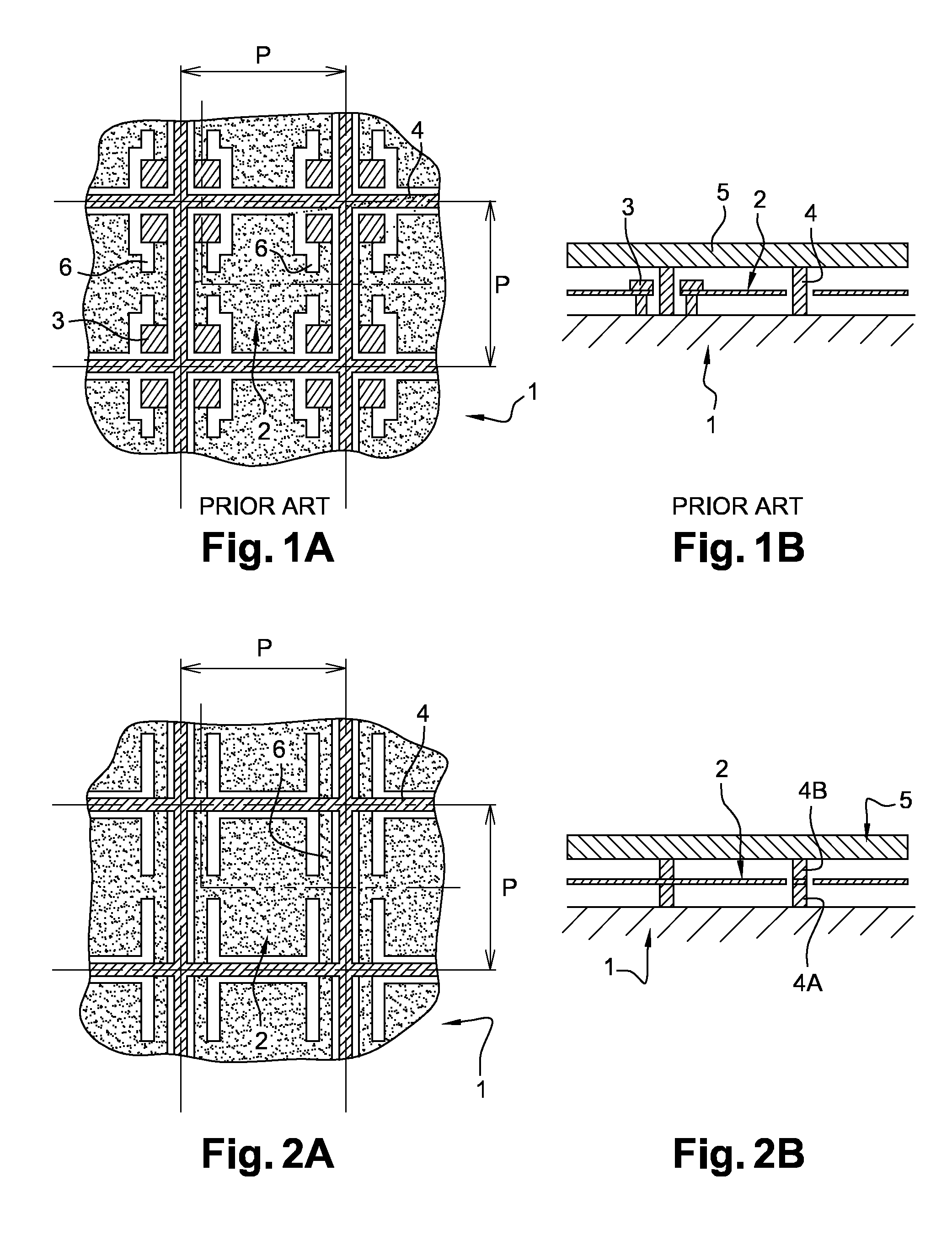

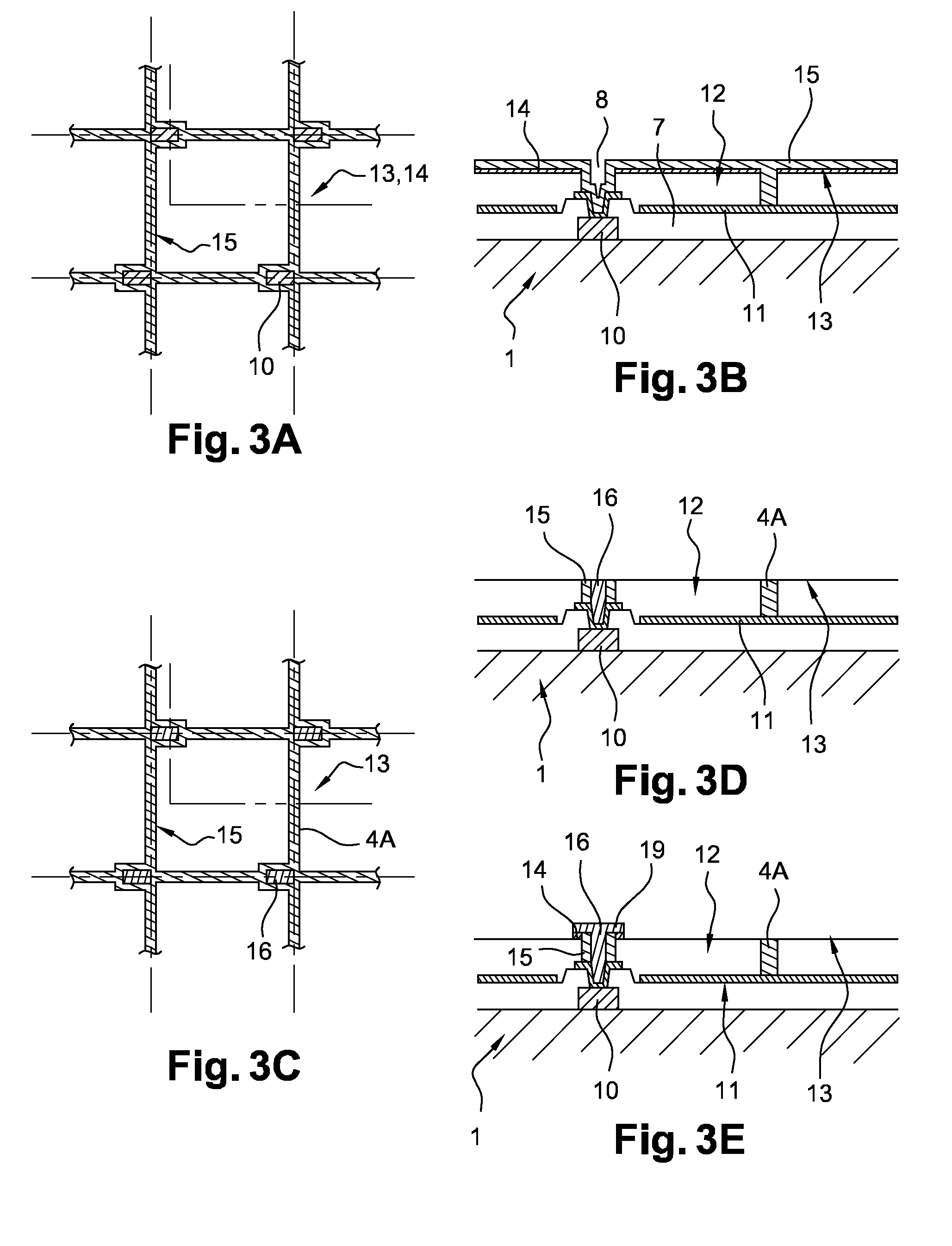

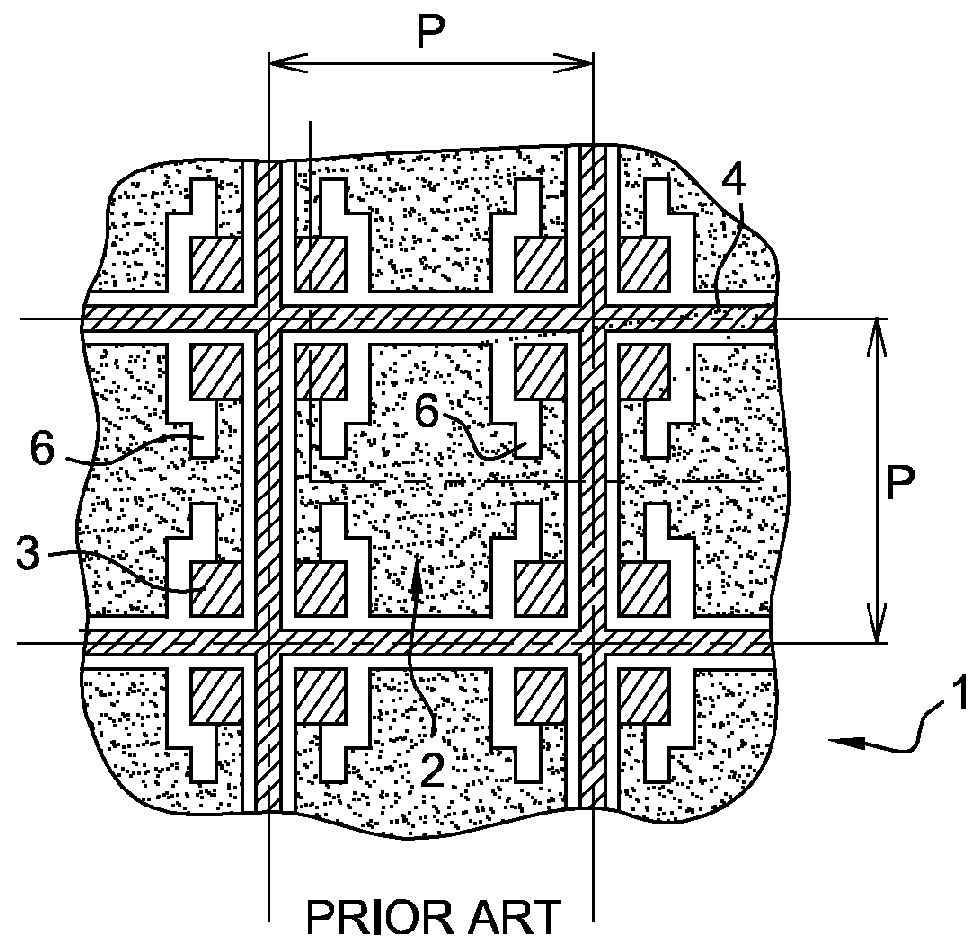

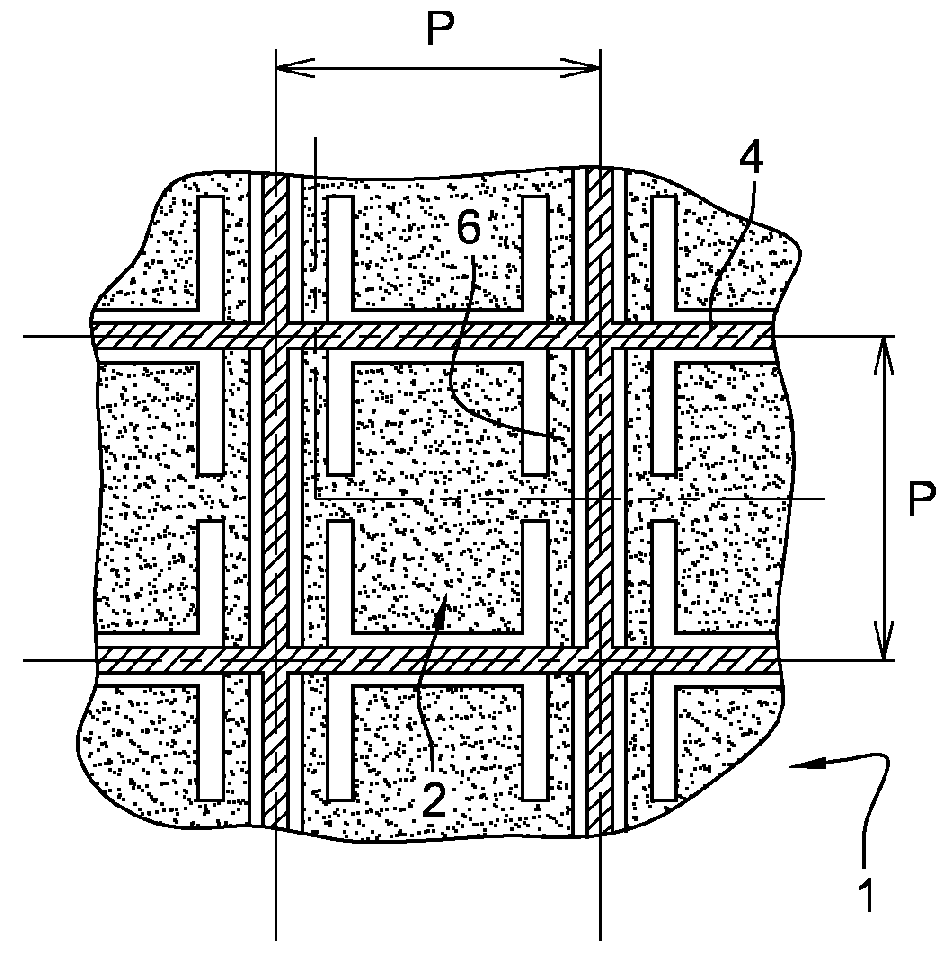

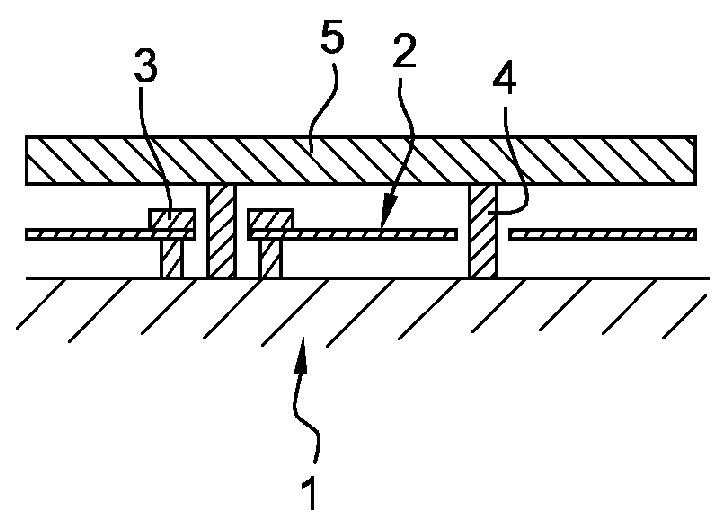

Electromagnetic radiation detector with micro-encapsulation, and device for detecting electromagnetic radiation using such detectors

ActiveUS20110141286A1Loss of sensitivityEliminate footprintTelevision system detailsColor television detailsRadiationElectromagnetic radiation

This electromagnetic radiation detector consists of a plurality of elementary detection micro-sites, each including a micro-detector provided with a membrane (2) that is sensitive to the radiation in question and each being provided in a micro-cavity or micro-capsule defined by a substrate (1), by an upper wall (5) used as a window that is transparent to said radiation and by side walls (4), said membrane (2) being suspended above substrate (1) by means of at least two support arms (6) that include an electrically conducting layer (17), with the ends of said arms (6) being anchored in side walls (4).

Owner:ULIS SAS

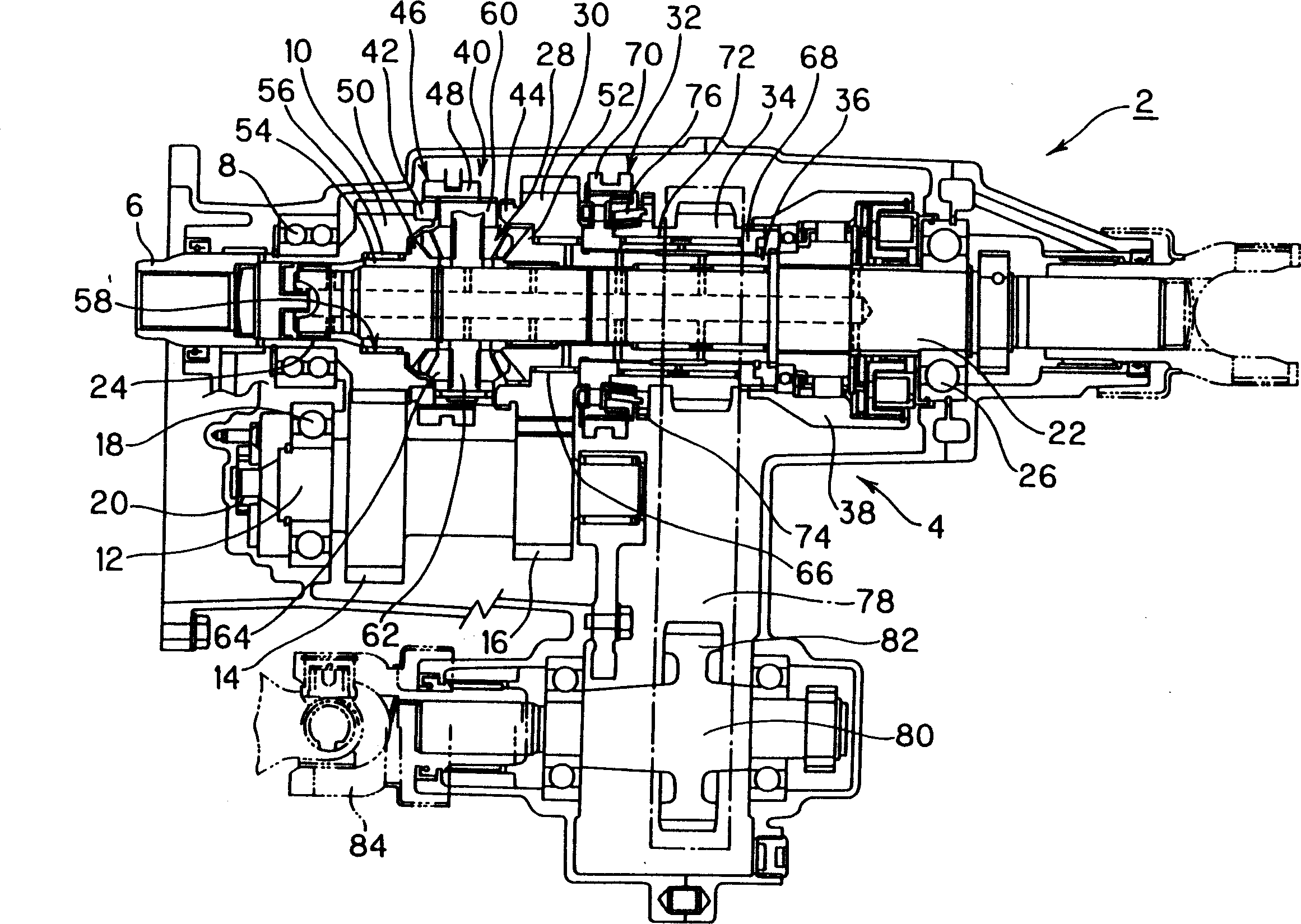

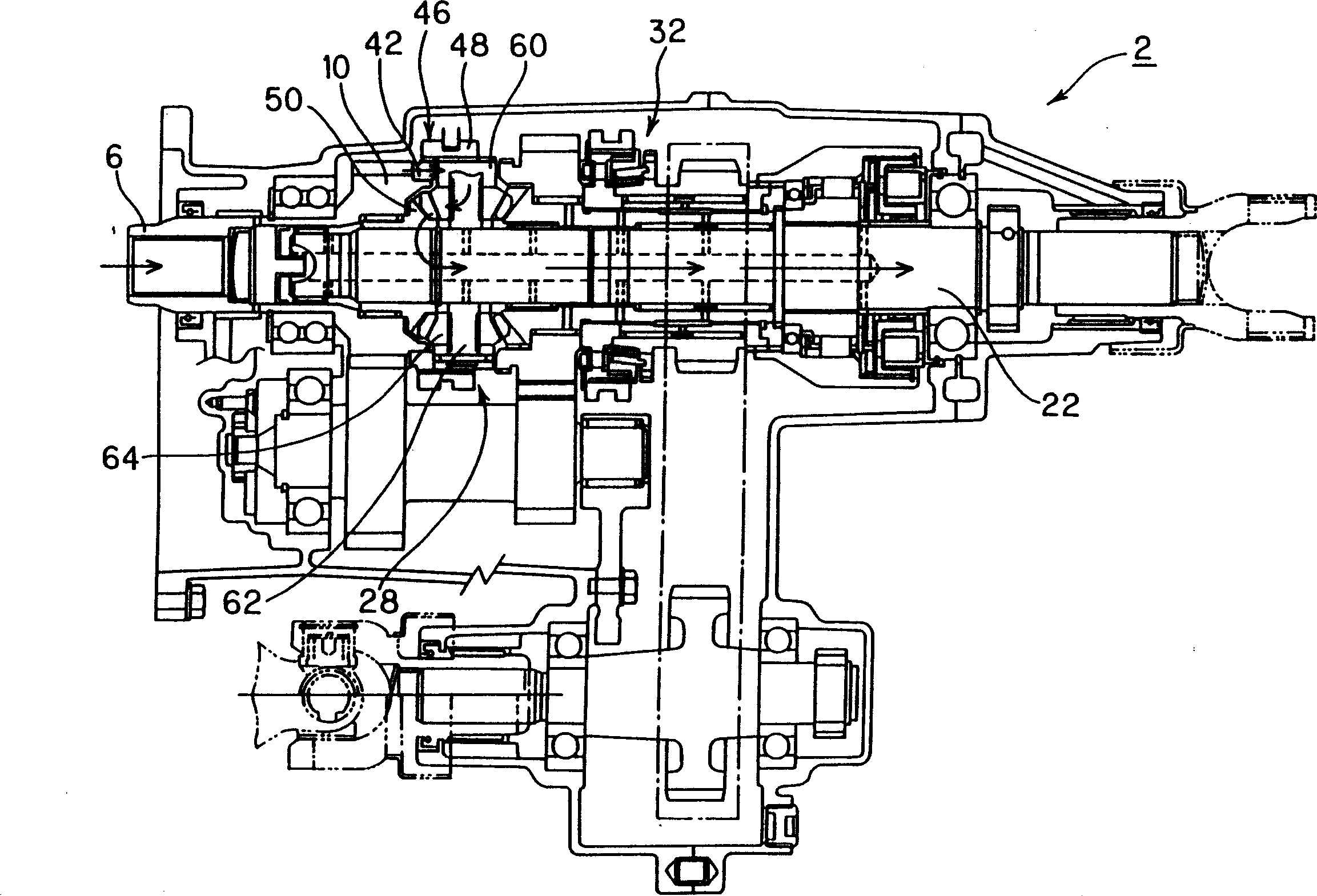

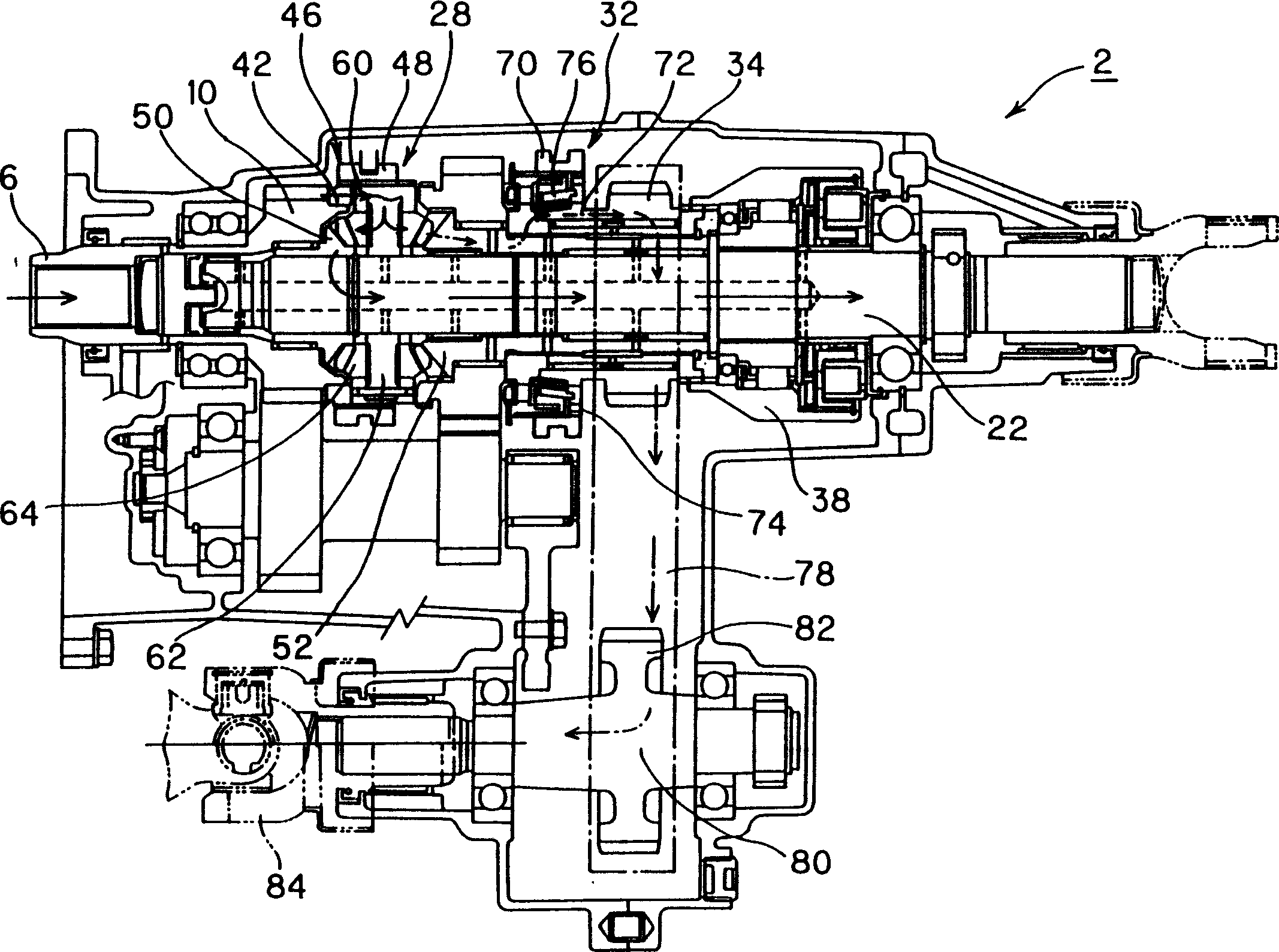

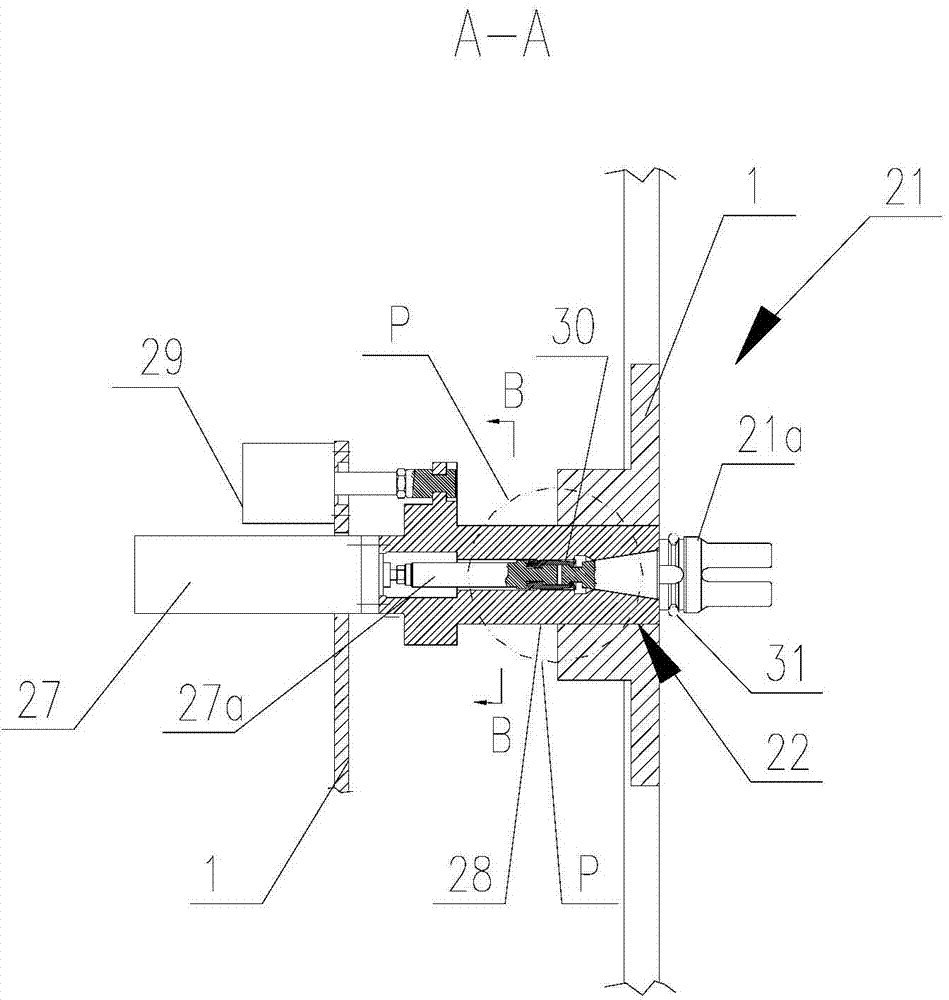

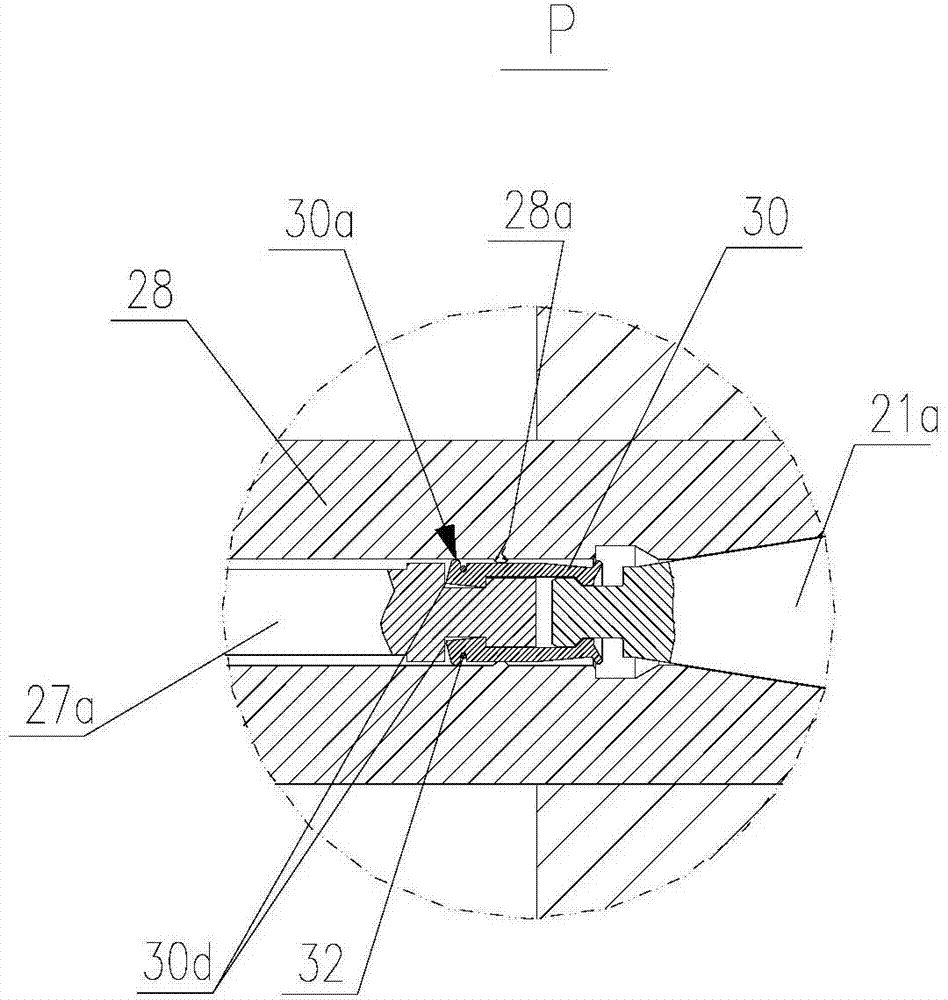

Transfer device for four-wheel driven vehicle

InactiveCN1513692AEliminate footprintShorten the axial lengthDifferential gearingsControl devicesLow speedEngineering

Owner:SUZUKI MOTOR CORP

Space sport mixer

InactiveCN101036863AImprove mixing efficiencyWell mixedRotating receptacle mixersShaking/oscillating/vibrating mixersHelical lineUniversal joint

A space motion mixer comprises a crank arm, a rocking bar, a container frame, a mixing container, a machine frame, a speed reduction gearing, a motor, etc. The mixing container with a helical line-shape scraping blade therein is arranged inside the container frame, two ends of the container frame are mechanically connected to the crank arm via a ball pair and the rocking bar via a universal joint respectively, and the crank arm and the rocking bar are respectively connected with a rotary pair and the machine frame. When the crank arm rotates in a complete alternation, the rocking bar swings around the machine frame, and the mixing container has a space motion containing rotation and movement; because of the space quick return motion and helical curve scraping blade, the materials in the container can generate a three-D projecting motion along axial, radial and circumferential directions for driving materials to be in a conglomeration and diffusion motion alternately for thorough mixing to have a good mixing effect and a high mixing efficiency, additionally, the invention is provided with simple structure, and can be controlled conveniently and manufactured easily.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

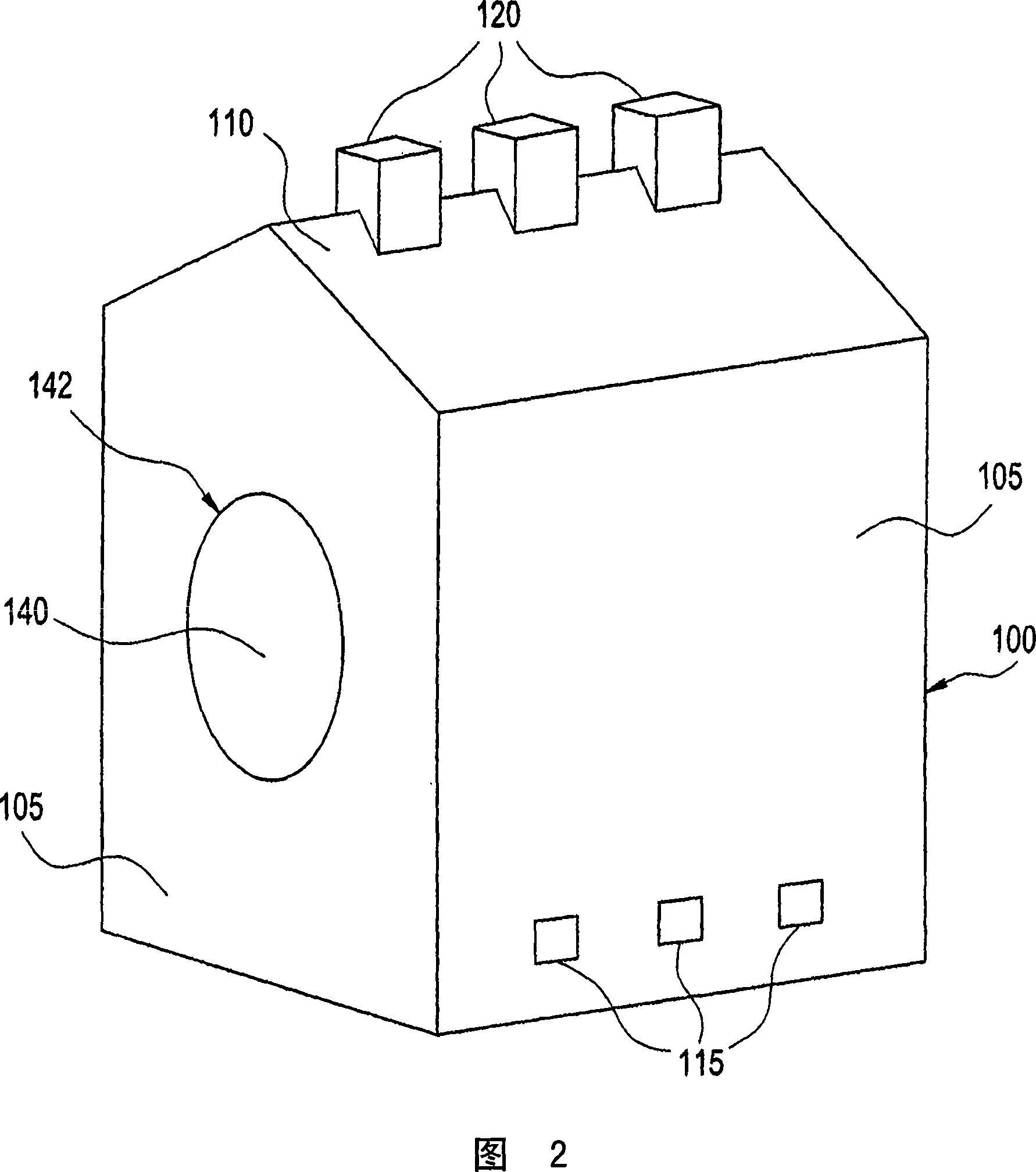

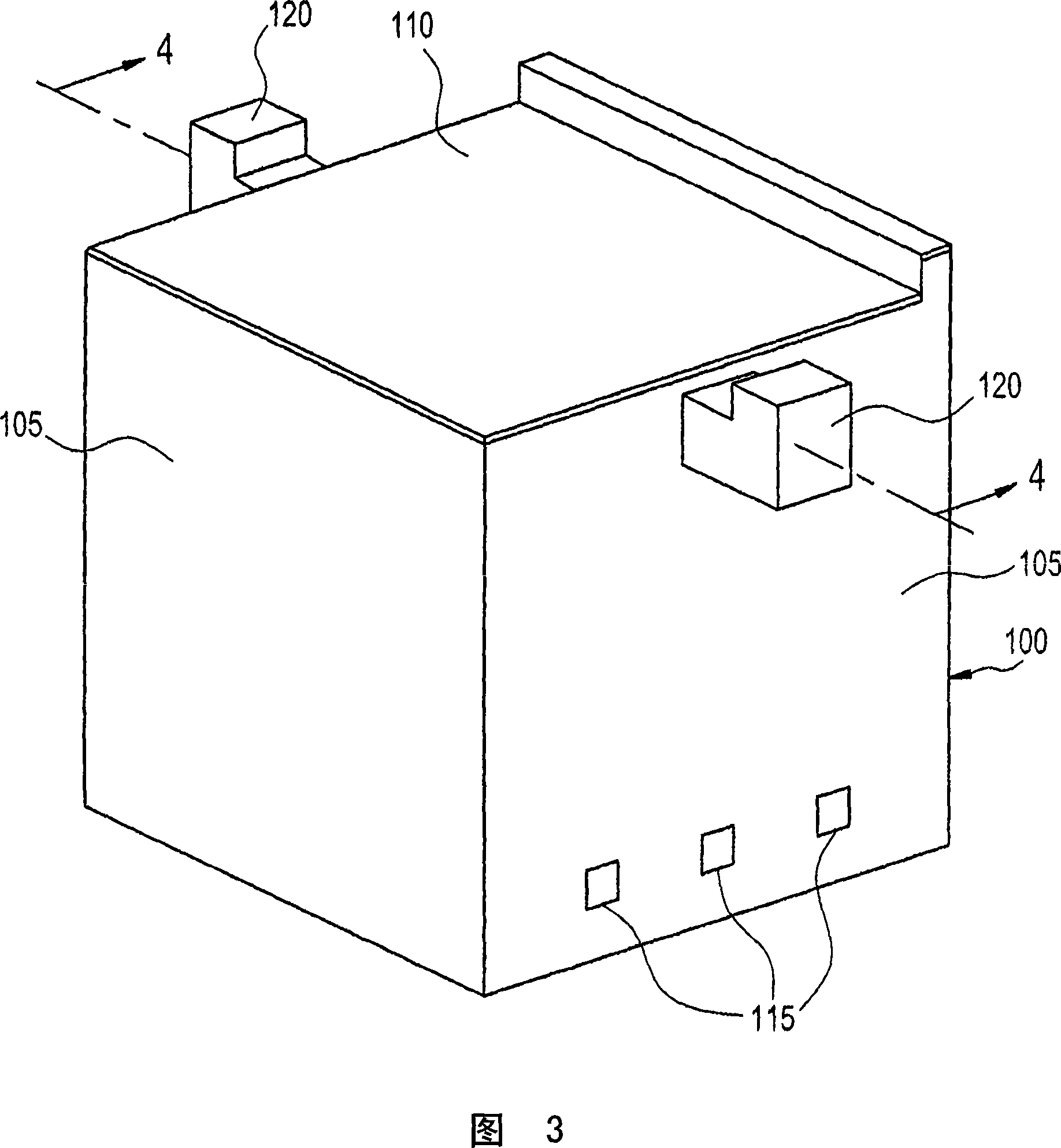

System and apparatus for enclosing equipment

InactiveCN101059195ACancel noiseEliminate or at least reduce noiseMachine framesMachines/enginesElectrical and Electronics engineeringCooling medium

An enclosure having a top and at least one side to surround equipment is disclosed. The enclosure includes a first set of ventilation ports disposed toward the bottom of the enclosure, a second set of ventilation ports disposed toward the top of the enclosure, and a baffle disposed proximate the top at the interior of the enclosure. The top of the opening of the first set of ventilation ports is disposed to be lower than the bottom of the equipment, the bottom of the opening of the second set of ventilation ports is disposed to be higher than the top of the equipment, and the baffle is configured to direct a cooling medium toward the second set of ventilation ports.

Owner:GENERAL ELECTRIC CO

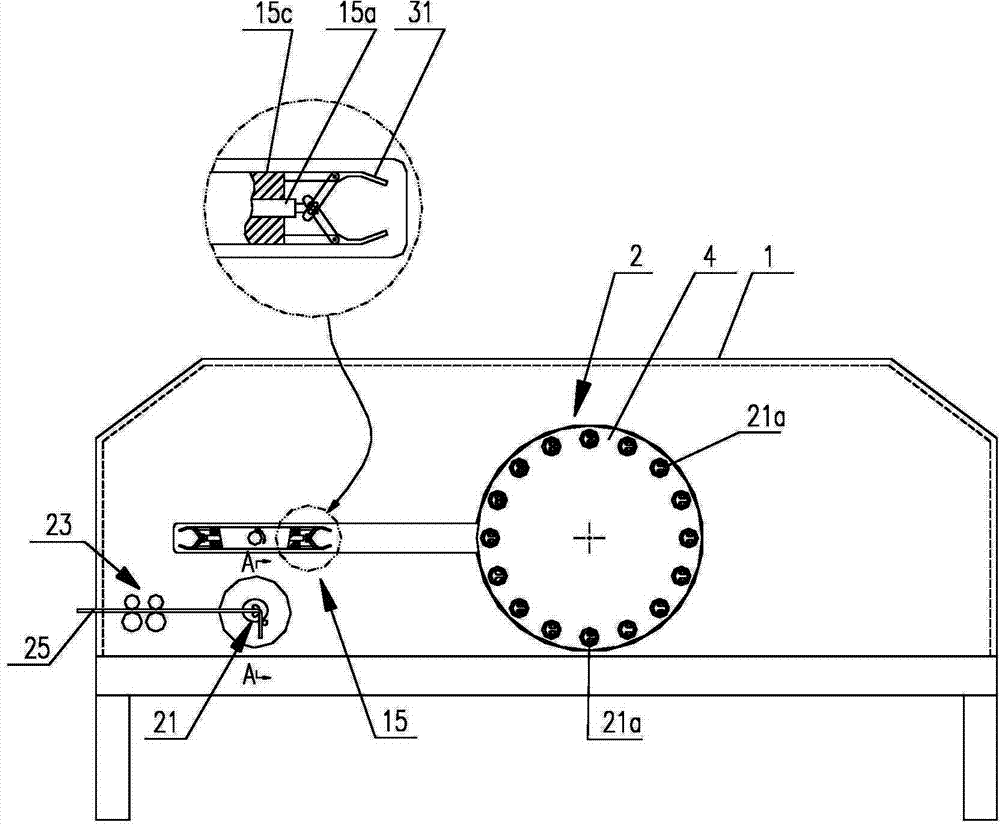

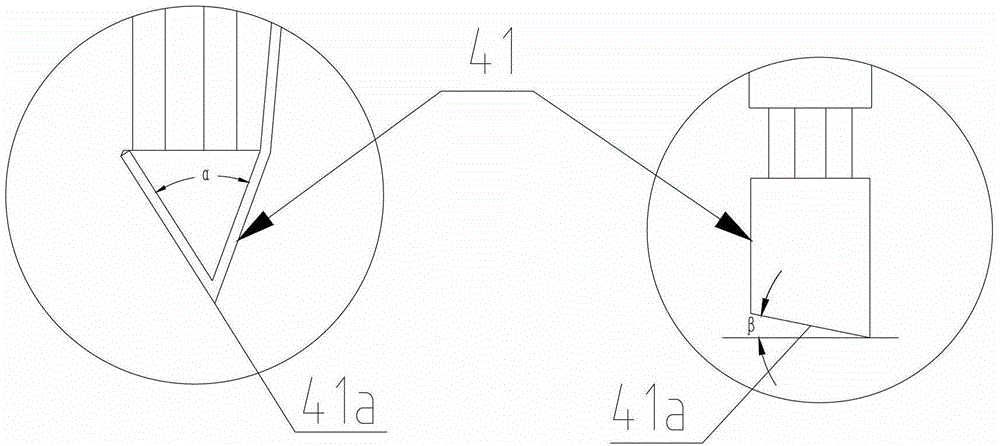

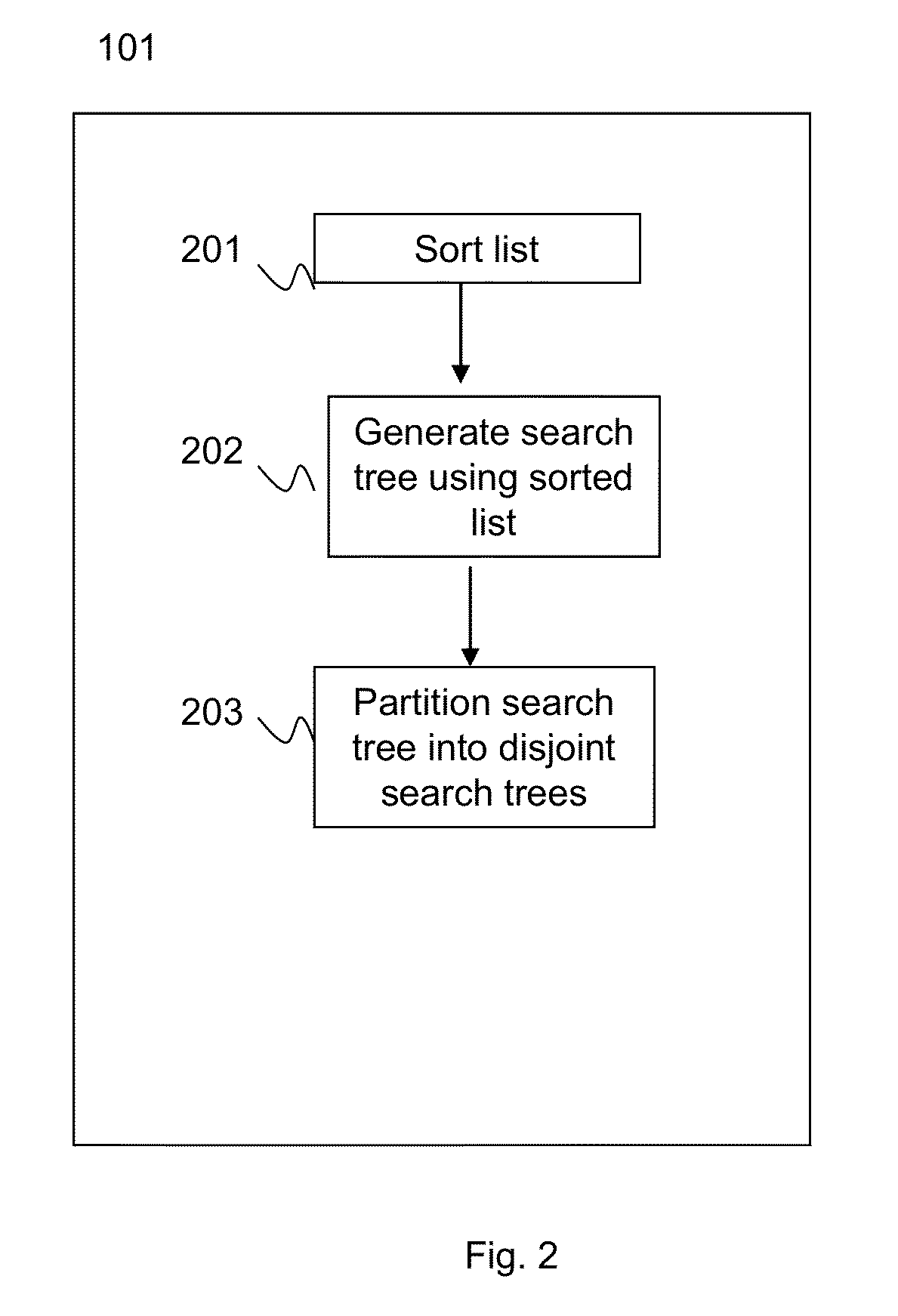

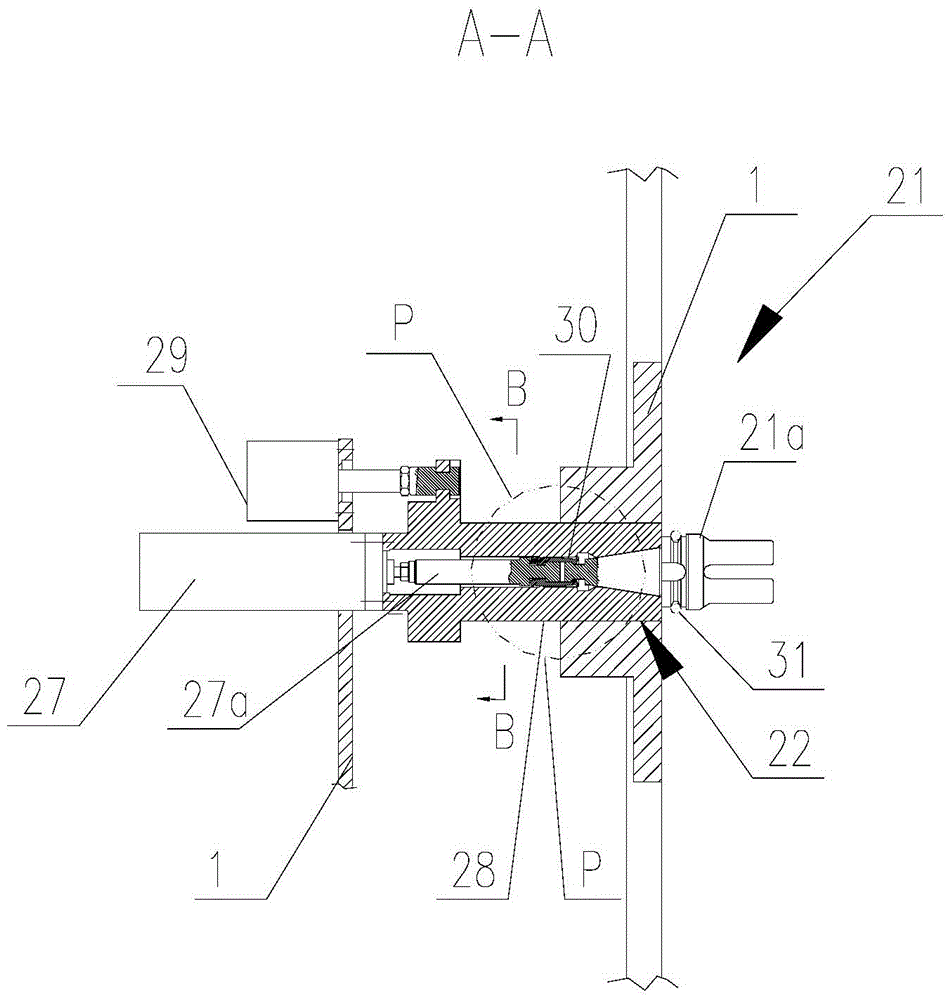

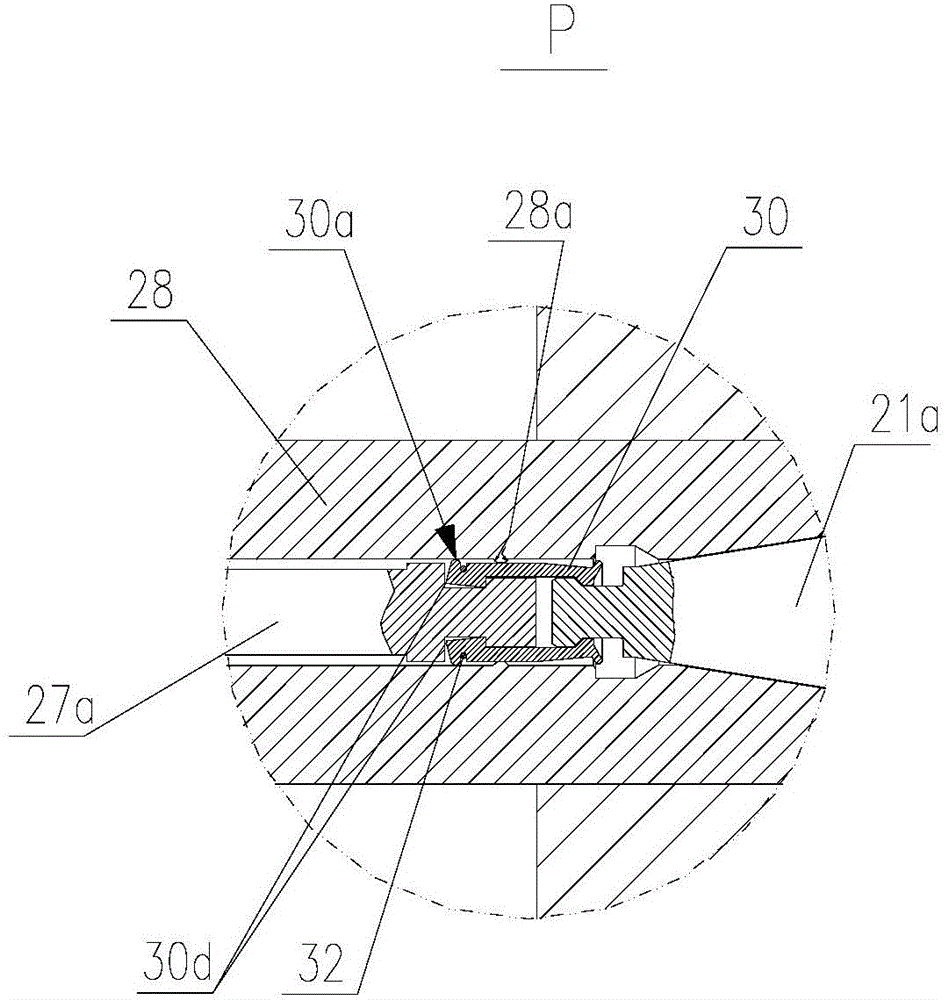

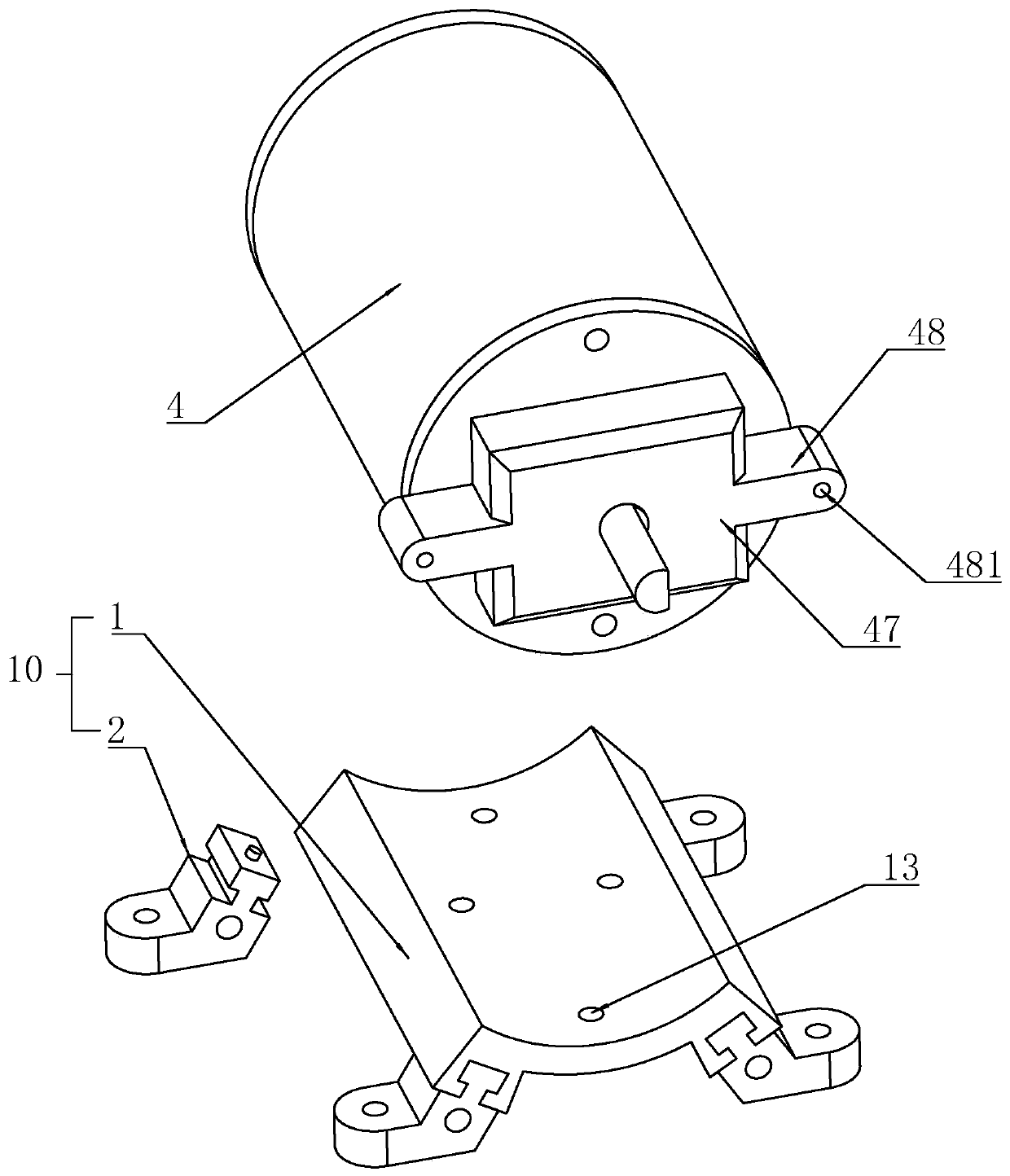

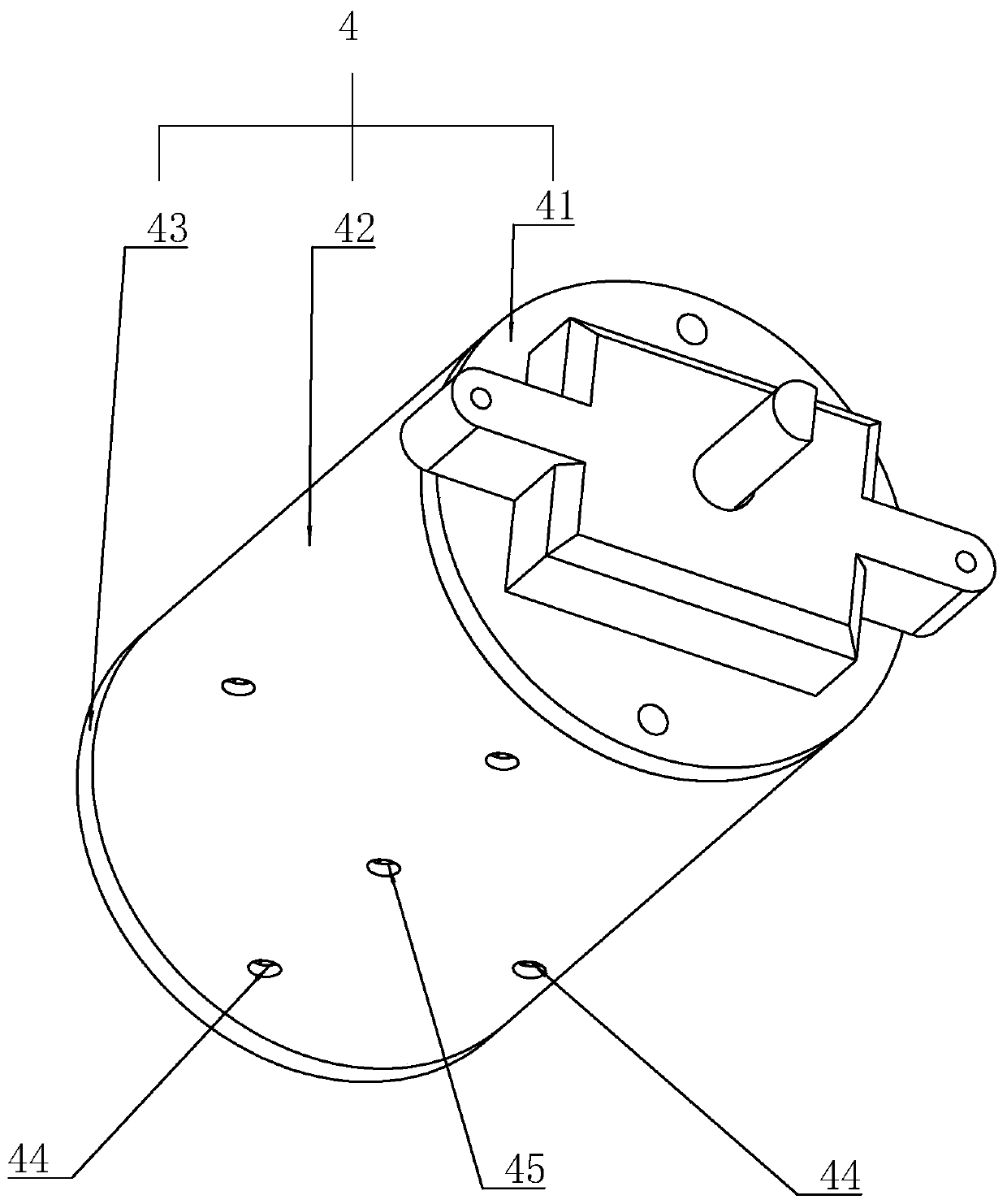

Automatic quick bending-die clamping device of reinforcement hoop bending machine

The invention discloses an automatic quick bending-die clamping device of a reinforcement hoop bending machine. The automatic quick bending-die clamping device structurally comprises a rack, a bending machine head, a die library and a manipulator; a plurality of bending dies are mounted on the outer side face of a die rotating plate in the die library, and the die rotating plate is connected with a rotating mechanism and an extension / retraction reciprocating mechanism; the manipulator is provided with the extension / retraction reciprocating mechanism and the rotating mechanism; and quick bending-die clamping device bodies are mounted on the bending machine head and the die rotating plate respectively. Each quick bending-die clamping device body comprises one bending die, a bending die fixing seat and an unclamping cylinder. The automatic quick bending-die clamping device has the advantages that the bending dies of the reinforcement hoop bending machine are connected to the quick bending-die clamping device bodies, and automatic bending die clamping can be completed through the manipulator and the matched die library; effective space of the rack of the hoop bending machine is utilized, and the automatic quick bending-die clamping device is compact and simple in structure, capable of bringing convenience to operators, high in automation level, stable in working, laborsaving, capable of increasing processing efficiency by 50%, lower in cost, convenient to maintain.

Owner:TJK MACHINERY TIANJIN

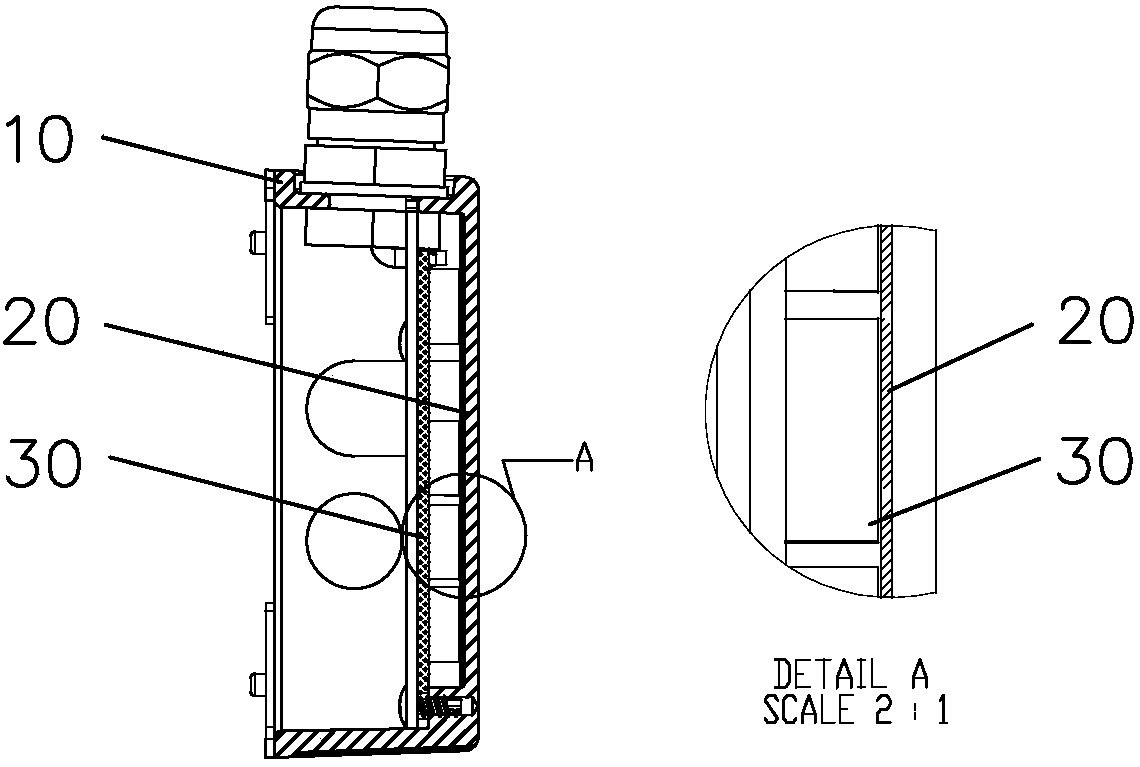

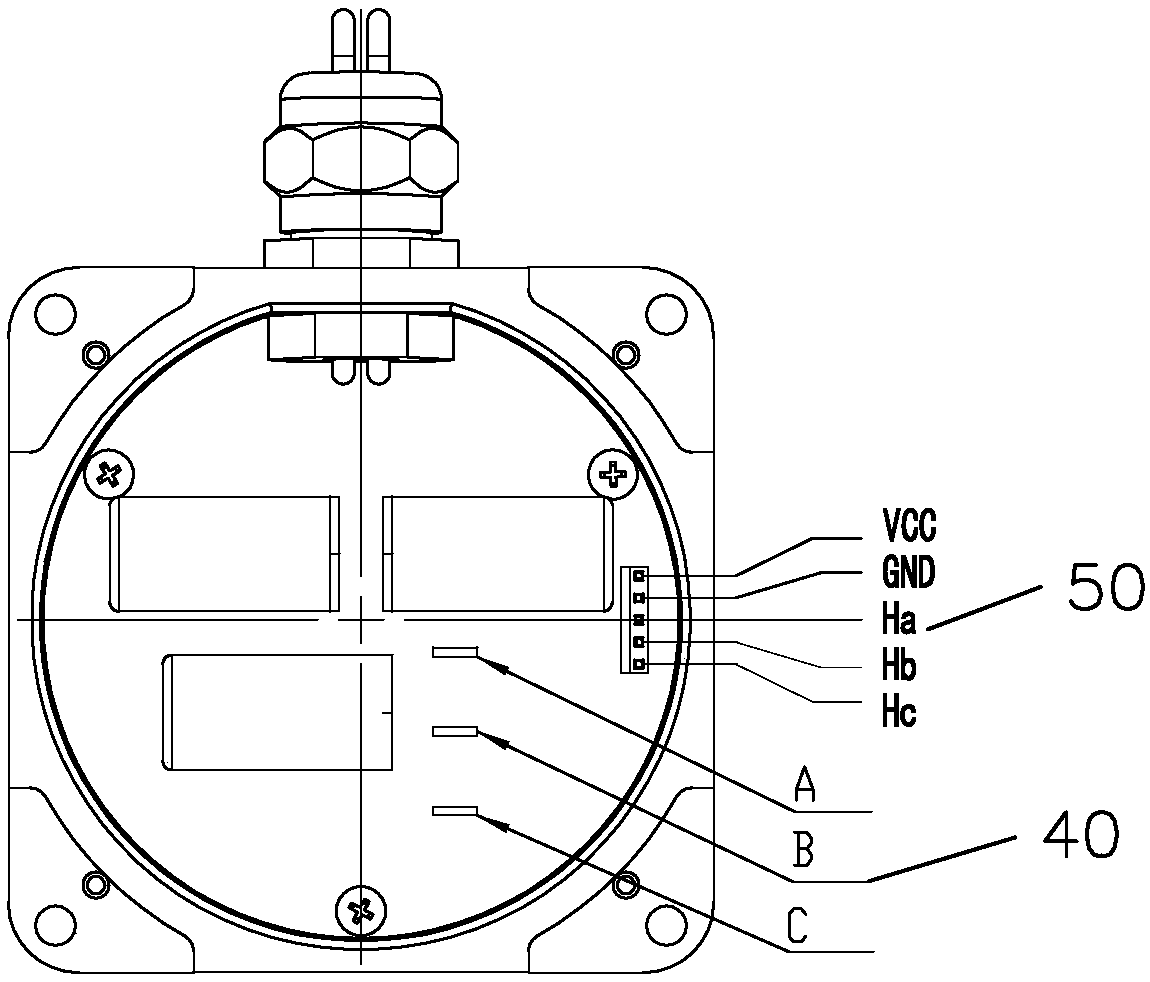

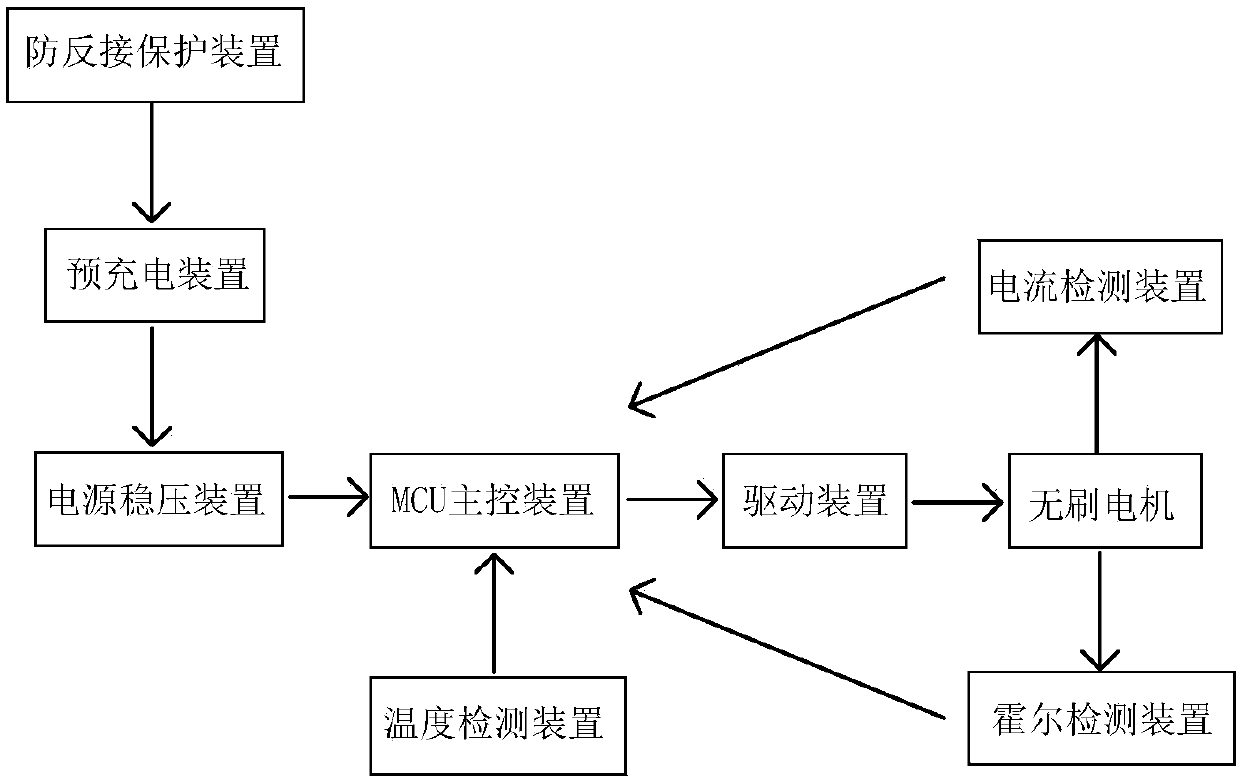

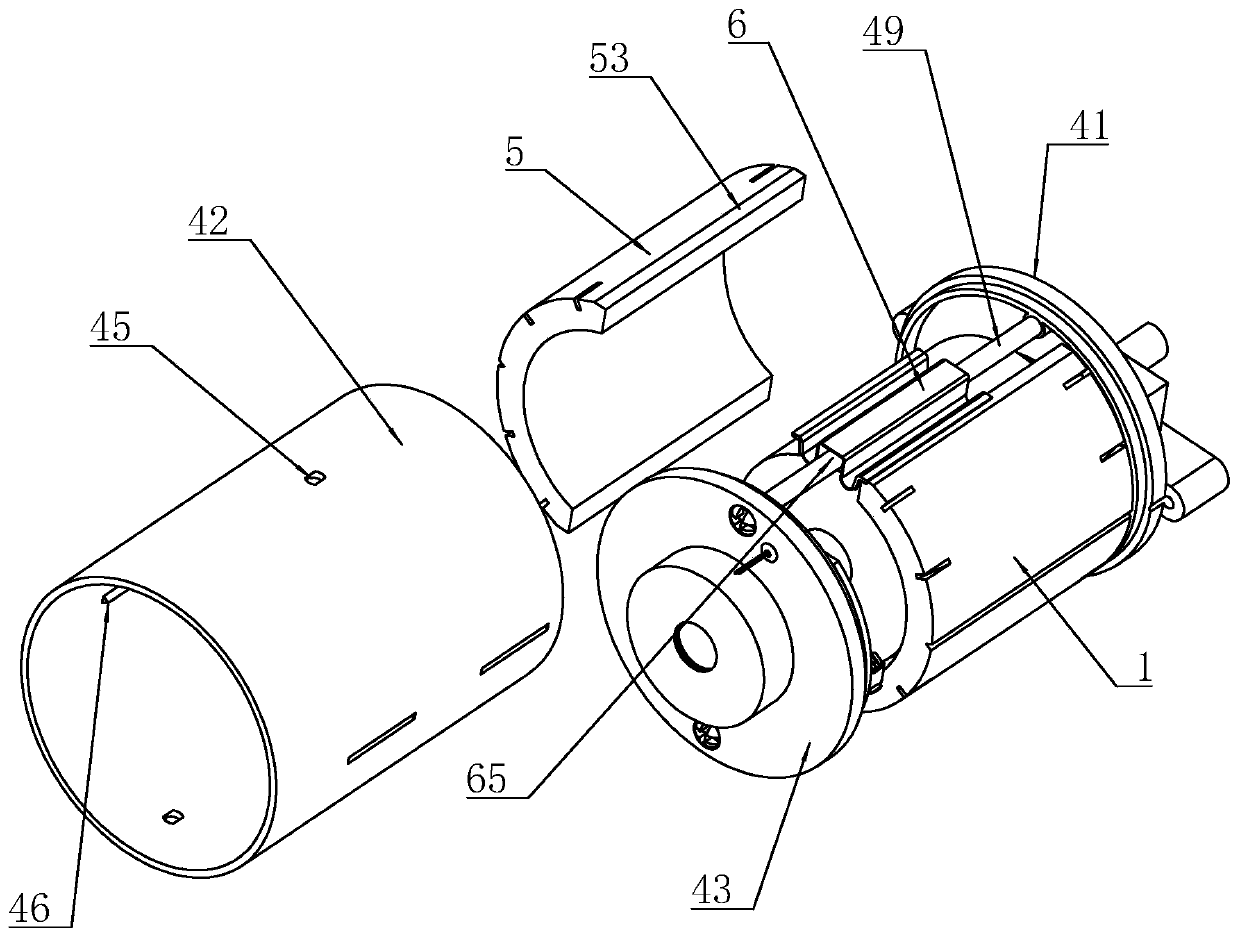

Brushless direct-current motor of water pump

PendingCN107565764AEliminate footprintCompact structureAssociation with control/drive circuitsElectricityBrushless motors

A brushless direct-current motor of a water pump comprises a brushless motor body and a controller. The brushless motor body comprises a front end cover, a back end cover, a stator and a Hall sensingdevice, wherein the stator is mounted between the front end cover and the back end cover and is connected with a three-phase input line, and the Hall sensing device is mounted on the stator and is connected with a Hall signal terminal. The controller is positioned in the brushless motor body, fixed on the back end cover and electrically connected with the three-phase input line. The Hall sensing device is electrically connected with a Hall detection device through the Hall signal terminal and inputs a Hall signal into the Hall detection device for detection. A MCU master control device is usedfor processing a signal detected by the Hall detection device and controlling a drive device to drive the brushless motor body to run and stop. The brushless direct-current motor of the water pump has the advantages that the brushless direct-current motor with the built-in controller avoids space occupancy of an external controller, thereby being more compact in system structure and easy to operate.

Owner:台山市江口电器制造有限公司

Automatic lifting steel bar feeding device in steel bar processing production line and its technology

ActiveCN102989933BSimple structureCompact structureMetal rolling arrangementsProduction lineEngineering

The invention discloses an automatic lifting type rebar feeder and automatic lifting type rebar feeding process in a rebar machining assembly line. The rebar feeder comprises a rack, a material absorbing mechanism, a discharging mechanism, a material guide mechanism and a control device; the material absorbing mechanism, the discharging mechanism, the material guide mechanism and the control device are arranged on the rack; the material absorbing mechanism comprises a material absorbing air cylinder and a magnetic absorbing device; the discharging mechanism comprises a discharging air cylinder and a stainless steel discharging rod; and the material guide mechanism comprises a material guide roller, a material guide roller supporting frame and a material guide air cylinder. The process is carried out by the following steps in sequence: 1) setting an original state; 2) absorbing and lifting a material; 3) discharging and supporting the material; 4) dividing and feeding the material; 5) discharging the material; and 6) drawing a rebar to move. The rebar feeder provided by the invention has the beneficial effects of simple structure, high working efficiency, labor saving, cost reduction and convenience in maintenance. The rebar feeder provided by the invention is hinged on the lateral face of rebar machining equipment, and moves along with the rebar machining equipment, so that a transportation procedure can be eliminated, the space occupied by the former procedure can be saved, and the application range is wider.

Owner:TJK MACHINERY TIANJIN

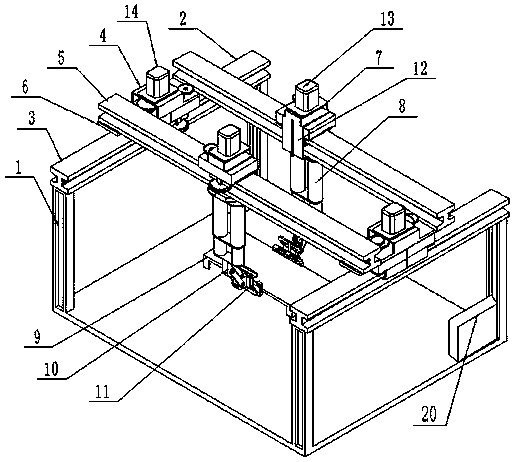

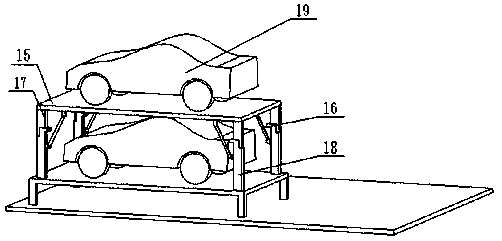

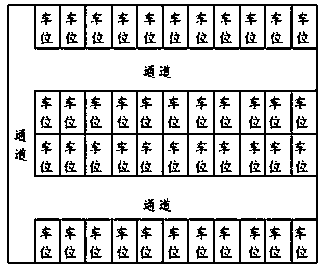

Travelling type double-arm intelligent parking system and method

ActiveCN110185303AIncrease the number ofEliminate occupied spaceParkingsAutomotive engineeringManipulator

The invention discloses a travelling type double-arm intelligent parking system and a method. The travelling type double-arm intelligent parking system comprises guide rail assemblies, two manipulatorassemblies and an intelligent control assembly for controlling actions of all parts in the whole parking process; the travelling type double-arm intelligent parking system further comprises a vehiclesupport for placing a to-be-parked vehicle; the guide rail assemblies comprise transverse guide rail assemblies and longitudinal guide rail assemblies; two groups of transverse guide rail assembliesare arranged side by side, are arranged above the ground of a parking lot through guide rail supports in a suspension manner and are positioned at two edges of the ground of the parking lot along thetransverse direction; the two manipulator assemblies are respectively and correspondingly arranged on two longitudinal guide rail assemblies and can slide on the two longitudinal guide rail assemblies, so that the movement of the two manipulator assemblies in the ground parking lot along all directions is finished by matching the transverse guide rail assemblies with the longitudinal guide rail assemblies; the two manipulator assemblies are used for clamping the vehicle support so as to finish clamping and releasing actions of the vehicle support and can vertically lift. According to the travelling type double-arm intelligent parking system and the method disclosed by the invention, the space utilization rate of the parking lot can be improved and the problem of difficult parking in a cityis effectively solved.

Owner:YANGTZE NORMAL UNIVERSITY

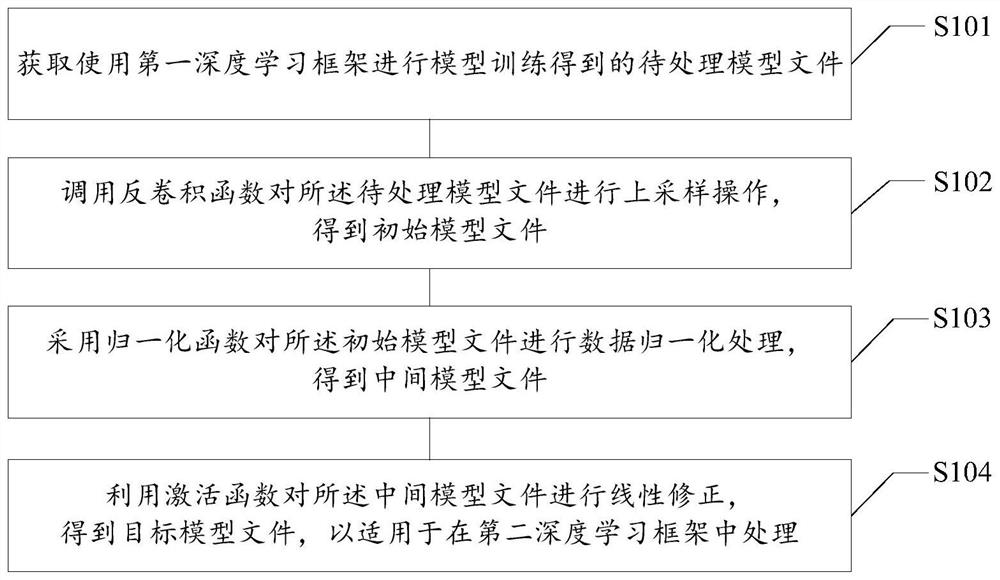

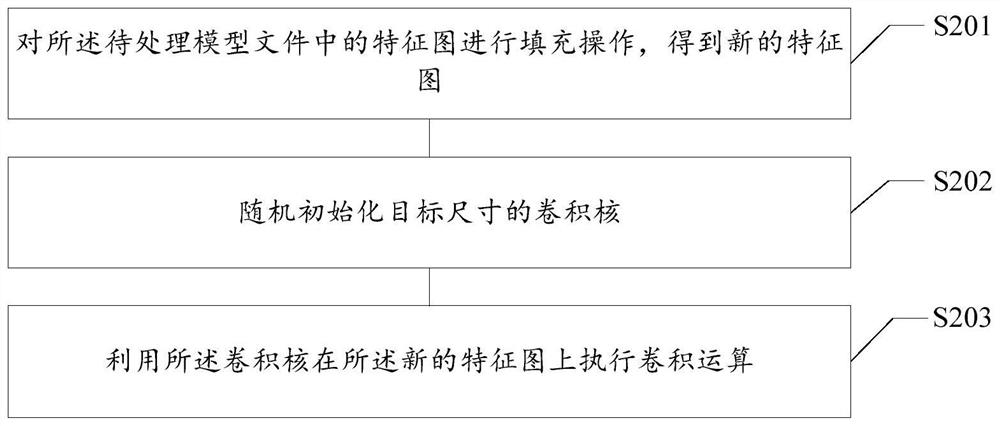

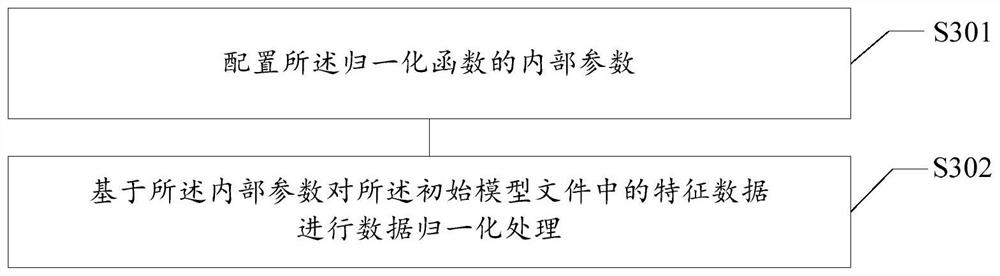

Deep learning model conversion deployment method and device, storage medium and electronic equipment

PendingCN114327525AAvoid Compatibility IssuesLow costNeural architecturesNeural learning methodsActivation functionEngineering

The invention relates to the technical field of artificial intelligence, in particular to a deep learning model conversion deployment method, a deep learning model conversion deployment device, a storage medium and electronic equipment. The deep learning model conversion deployment method comprises the steps of obtaining a to-be-processed model file obtained by performing model training by using a first deep learning framework; calling a deconvolution function to perform up-sampling operation on the to-be-processed model file to obtain an initial model file; performing data normalization processing on the initial model file by adopting a normalization function to obtain an intermediate model file; and performing linear correction on the intermediate model file by using an activation function to obtain a target model file which is suitable for processing in a second deep learning framework. According to the deep learning model conversion deployment method provided by the invention, the technical problems of large development amount, poor precision and high cost when a pytorch model is converted into a TensorRT model for deployment in the prior art can be solved.

Owner:JINGDONG KUNPENG (JIANGSU) TECH CO LTD

Integrated processes for producing fuels and biofertilizers from biomass and products produced

ActiveUS9365461B2Reduce, orEliminate footprintElectrical coke oven heatingBio-organic fraction processingPhylum CyanobacteriaGHG footprint

An IBTL system having a low GHG footprint for converting biomass to liquid fuels in which a biomass feed is converted to liquids by direct liquefaction and the liquids are upgraded to produce premium fuels. Biomass residues from the direct liquefaction, and optionally additional biomass is pyrolyzed to produce structured biochar, hydrogen for the liquefaction and upgrading, and CO2 for conversion to algae, including blue green algae (cyanobacteria) in a photobioreactor (PBR). Produced algae and diazotrophic microorganisms are used to produce a biofertilizer that also contains structured biochar. The structured biochar acts as a nucleation agent for the algae in the PBR, as a absorption agent to absorb inorganics from the biomass feed to direct liquefaction or from the liquids produced thereby, and as a water retention agent in the biofertilizer. The ratio of cyanobacteria to diazotrophic microorganisms in the biofertilizer can be selected to optimize the so as to achieve desired total chemically active carbon and nitrogen contents in the soil for a given crop.

Owner:ACCELERGY CORP +1

Electromagnetic radiation detector with micro-encapsulation, and device for detecting electromagnetic radiation using such detectors

ActiveUS8866082B2Loss of sensitivityEliminate footprintTelevision system detailsMaterial analysis by optical meansElectromagnetic radiationMicro-encapsulation

This electromagnetic radiation detector consists of a plurality of elementary detection micro-sites, each including a micro-detector provided with a membrane (2) that is sensitive to the radiation in question and each being provided in a micro-cavity or micro-capsule defined by a substrate (1), by an upper wall (5) used as a window that is transparent to said radiation and by side walls (4), said membrane (2) being suspended above substrate (1) by means of at least two support arms (6) that include an electrically conducting layer (17), with the ends of said arms (6) being anchored in side walls (4).

Owner:ULIS SAS

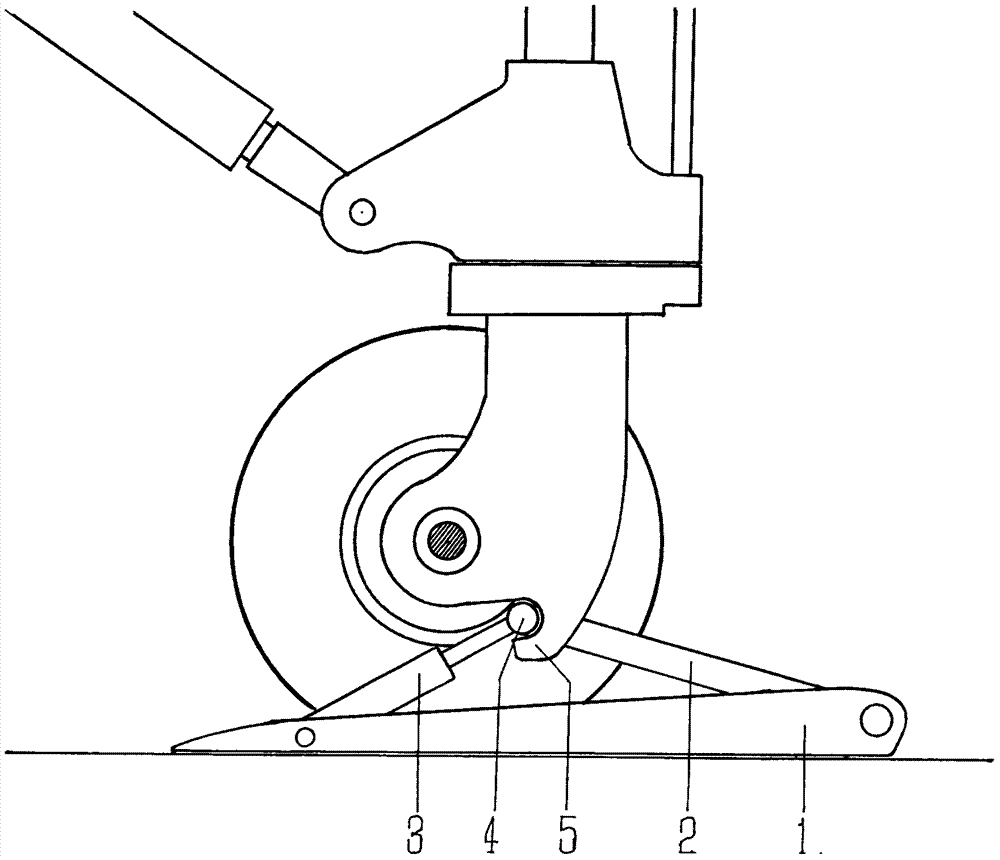

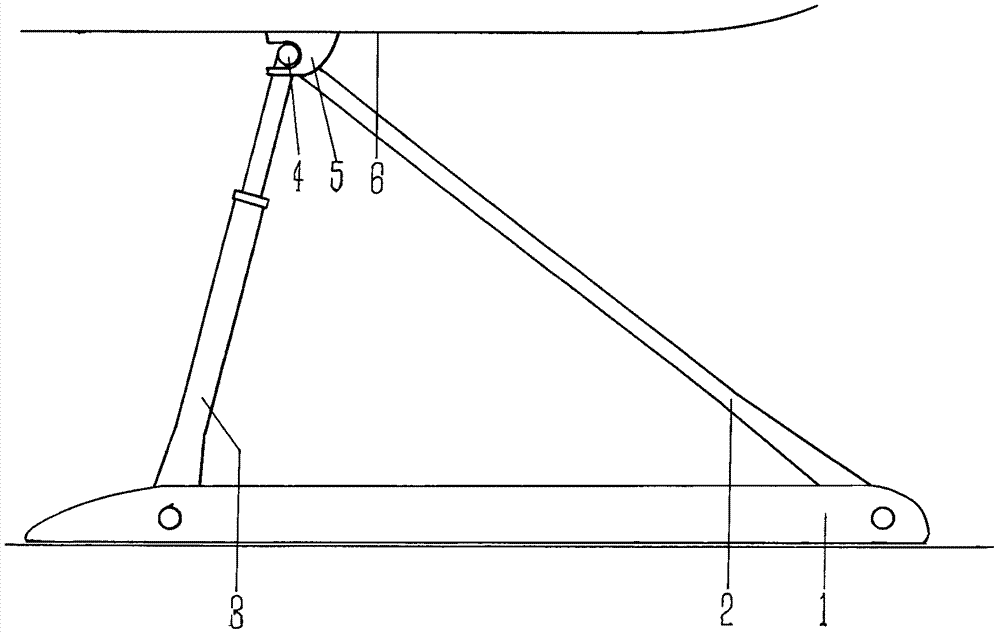

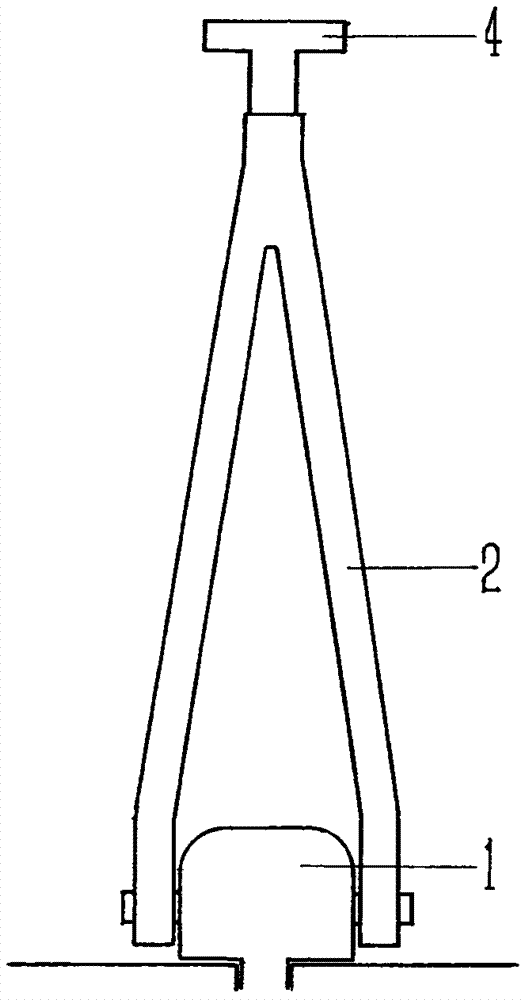

Tractive connection device between aircraft carrier catapult and carrier-based aircraft

InactiveCN107399441ASimple structureEasy to manufactureLaunching/towing gearCatapultAerospace engineering

The invention discloses a tractive connection device between an aircraft carrier catapult and a carrier-based aircraft. The device comprises a catapult gliding shuttle, a traction rod, a damping buffer rod, a hook and a hanging nose and is characterized in that the traction rod, the damping buffer rod and the hook are arranged on the catapult gliding shuttle, and the carrier-based aircraft is only provided with the hanging nose matched with the carrier-based aircraft. Compared with the prior art, the device has the beneficial effects of being simple in structure, firm, reliable, easy to manufacture, convenient to use and the like, the advantages of reducing the heavy and the space occupying of the catapult type carrier-based aircraft, reducing the manufacturing difficulty, the operation difficulty and maintaining difficulty of the carrier-based aircraft and the like are achieved, and the good popularization and application value is achieved.

Owner:董兰田

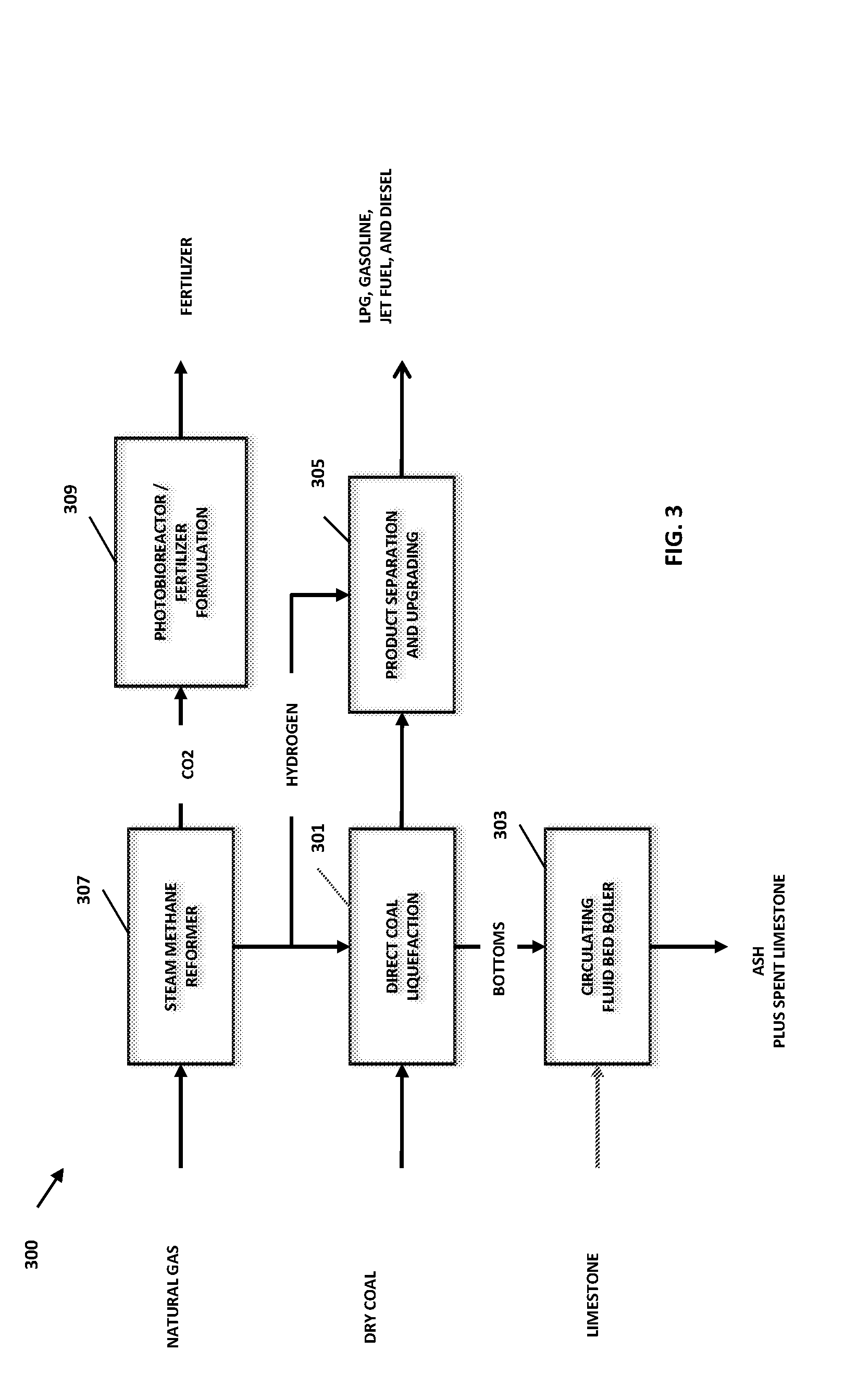

Integrated Coal To Liquids Process With Co2 Mitigation Using Algal Biomass

InactiveUS20170015602A1High thermal efficiencyReduced footprintBioreactor/fermenter combinationsBio-organic fraction processingMethane reformerGHG footprint

An ICBTL system and method having a low GHG footprint for converting coal or coal and biomass to liquid fuels and a biofertilizer in which a carbon-based feed is converted to liquids by direct liquefaction and optionally by indirect liquefaction and the liquids are upgraded to produce premium fuels. CO2 produced by the process is used to a produce cyanobacteria containing algal biomass and other photosynthetic microorganisms in a photobioreactor. Optionally, lipids extracted from the some of the algal biomass is hydroprocessed to produce fuel components and biomass residues and the carbon-based feed our gasified to produce hydrogen and syngas for the direct and indirect liquefaction processes. Some or all of the algal biomass and photosynthetic microorganisms are used to produce a natural biofertilizer. CO2 may also be produced by a steam methane reformer for supplying CO2 to produce the algal biomass and photosynthetic microorganisms.

Owner:ACCELERGY CORP

Display brightness adjustment

ActiveUS9412296B2Promote resultsLow costCathode-ray tube indicatorsInput/output processes for data processingSensor arrayDisplay device

A display comprising an array of pixels having individually adjustable brightness levels; an array of light sensors fixed relative to the pixel array; and a brightness controller for estimating a glare footprint on the pixel array from light level data provided by the sensor array and for adjusting the relative brightness levels of pixels that fall in the estimated glare footprint.

Owner:INT BUSINESS MASCH CORP

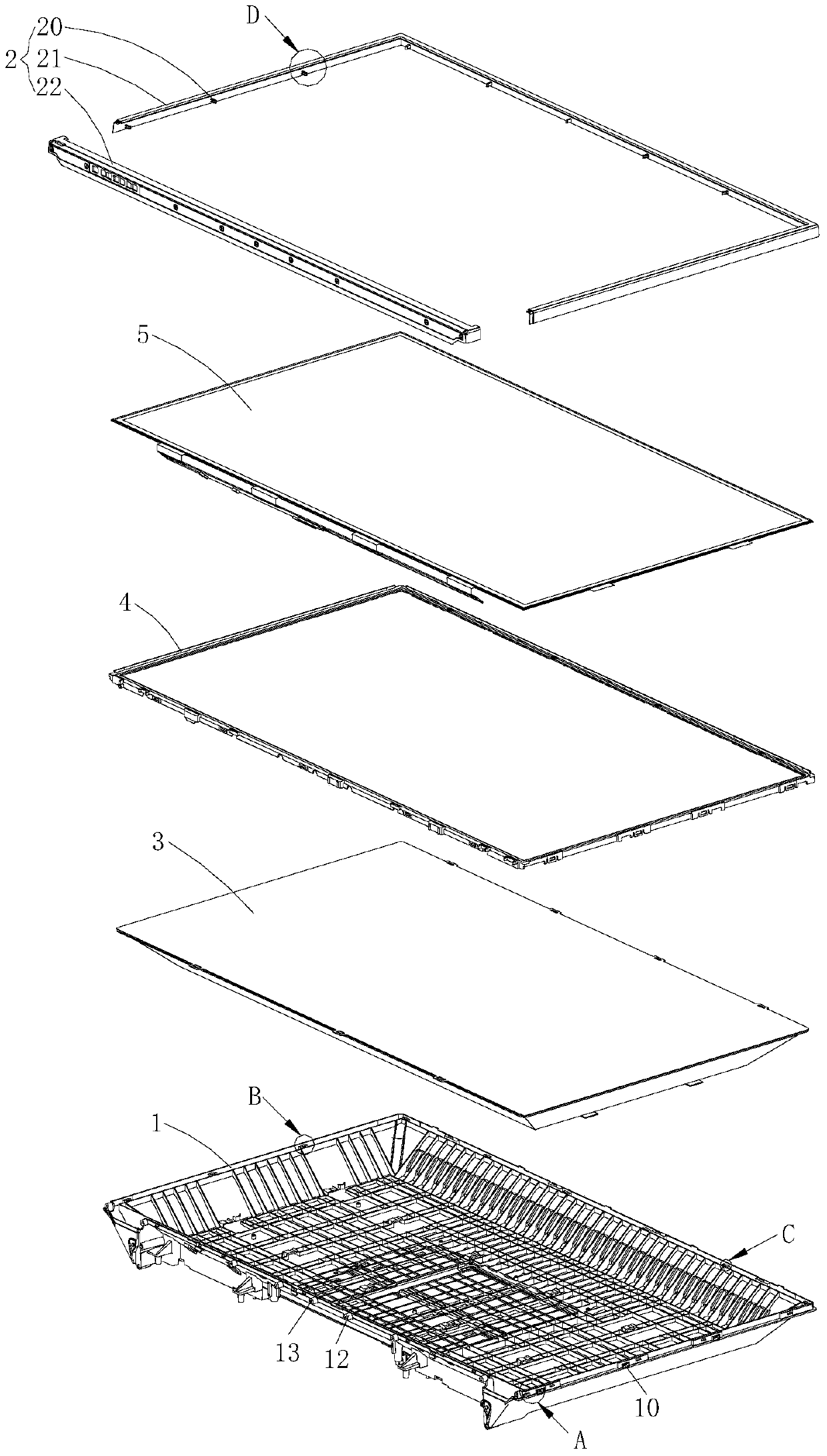

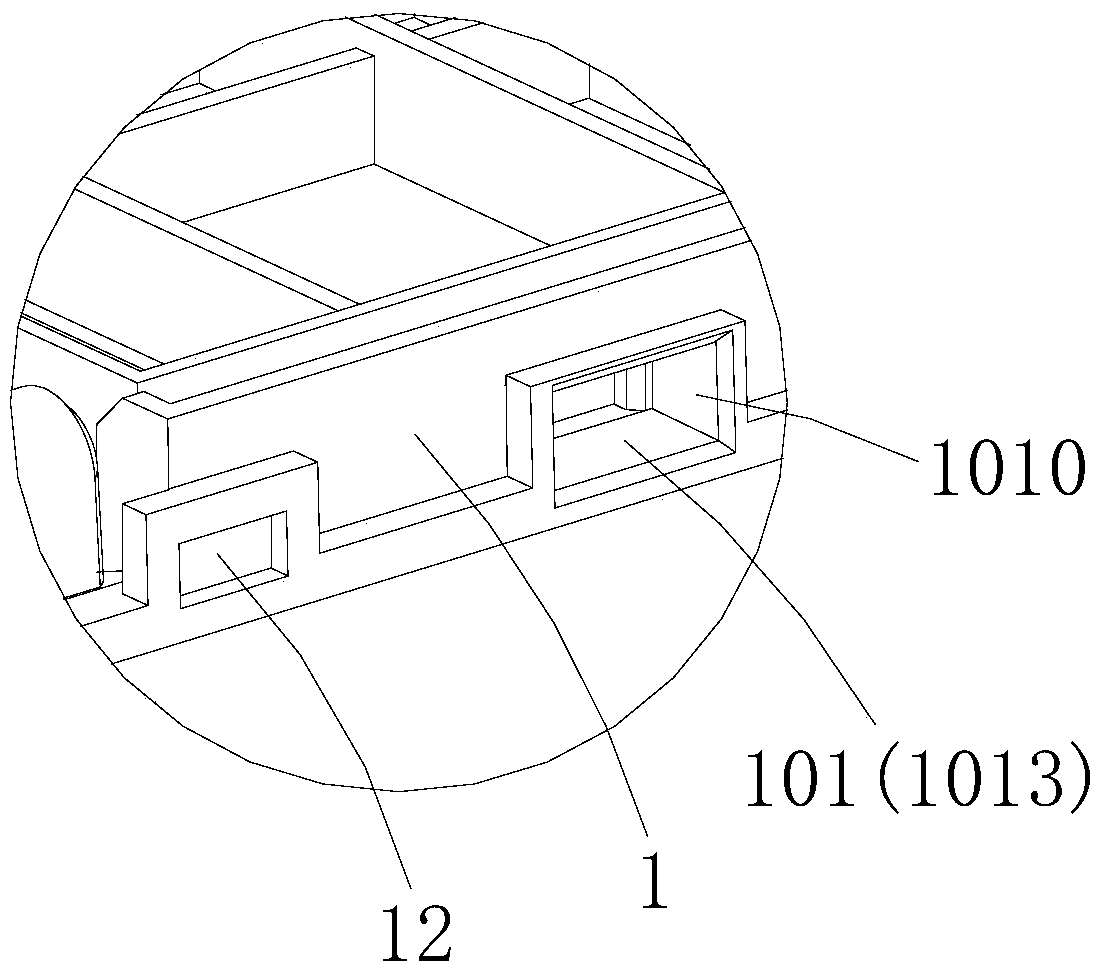

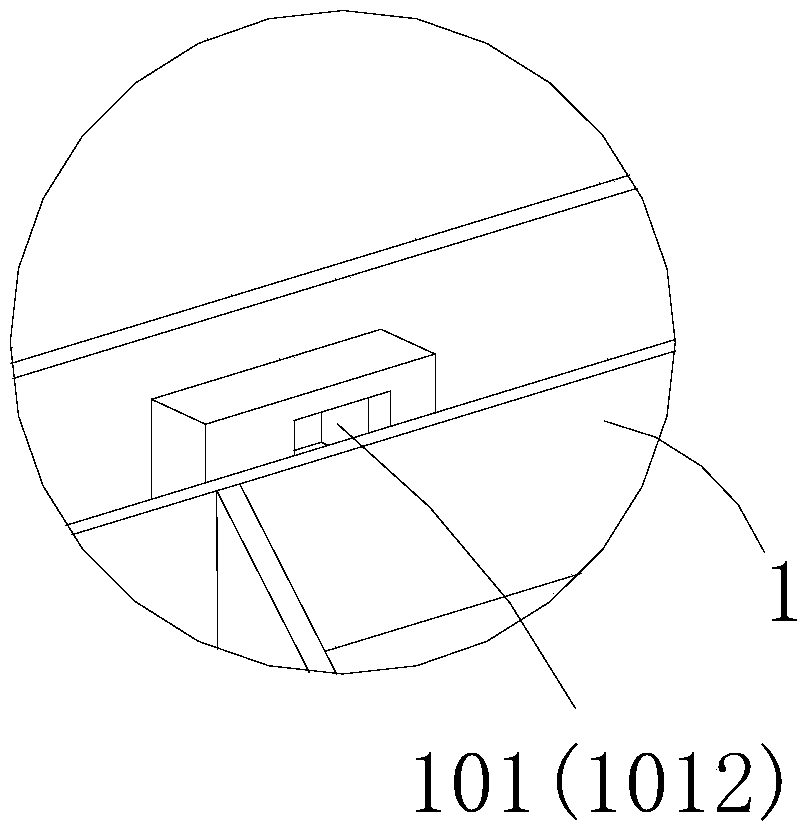

Surface frame installation structure of liquid crystal display device and liquid crystal display device

ActiveCN105652502BEliminate footprintReduce border widthNon-linear opticsLiquid-crystal displayEngineering

The invention is applicable to the field of liquid crystal display equipment and discloses a face frame installation structure of liquid crystal display equipment and the liquid crystal display equipment. The face frame installation structure of the liquid crystal display equipment comprises a main case shell and a face frame installed on the front side portion of the main case shell, a hole buckling structure is formed in the outer rim of the main case shell in the side direction, a hole locking structure is arranged on the inner wall of the face frame in the side direction in a protruding mode, and the hole locking structure is connected with the hole buckling structure in the side direction in a buckled mode. According to the face frame installation structure of the liquid crystal display equipment and the liquid crystal display equipment, connection between the face frame and the main case shell is achieved in a mode of conducting buckled connection in the side direction, the problem that when the face frame is connected with the main case shell in an existing mode of conducting buckled connection in the forward direction, occupied space is generated due to frame insertion limitation is effectively eliminated, thereby the frame width of a complete machine can be decreased to the greatest extent, meanwhile, the problem that when the face frame is connected with the main case shell in an existing mode of locking screws in the side direction, the screws are exposed in product appearance, so that a bad appearance effect is caused to the entire appearance of a product is solved fundamentally, and finally the effects of giving consideration to super narrowness and super thinness of the product and attractive appearance are finally achieved.

Owner:HEFEI HUIKE JINYANG TECH

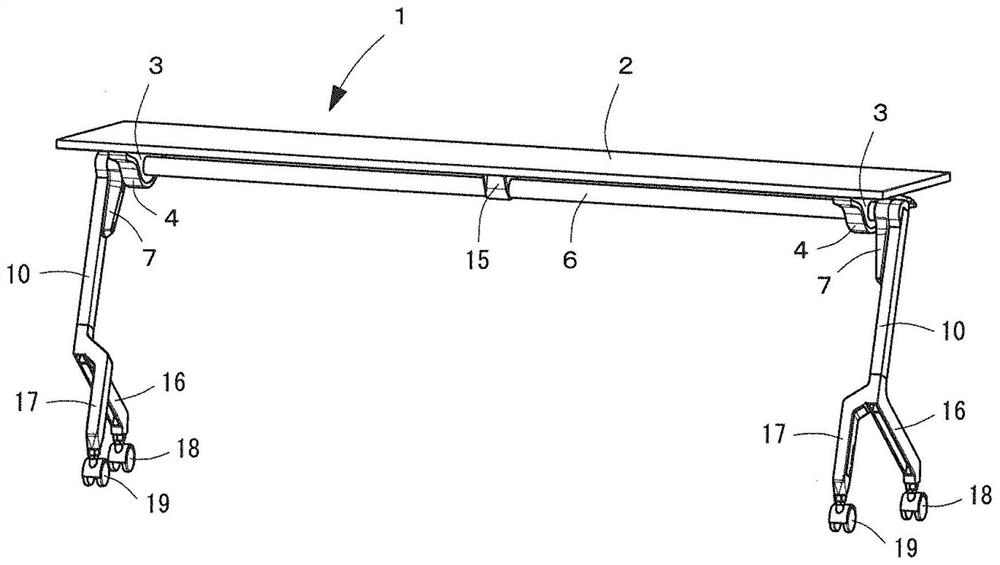

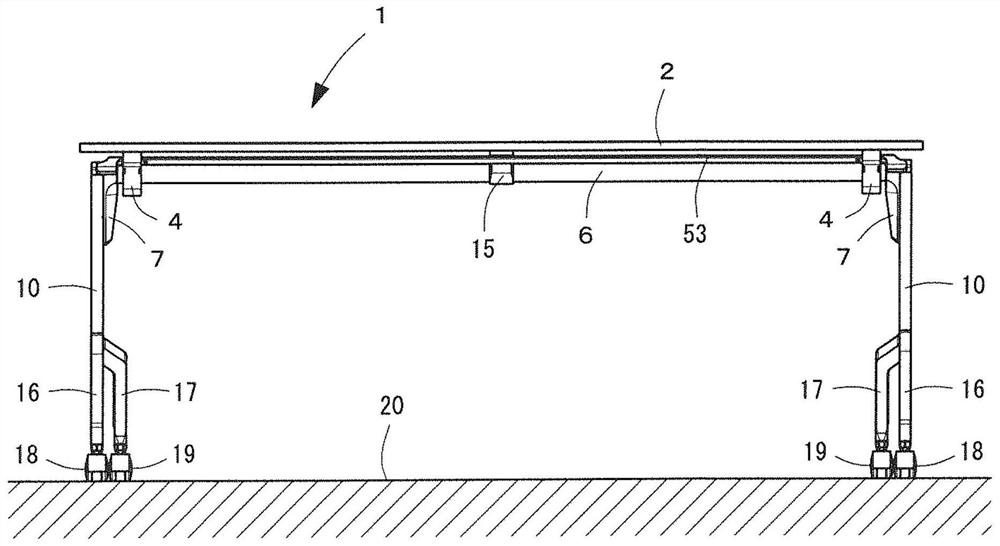

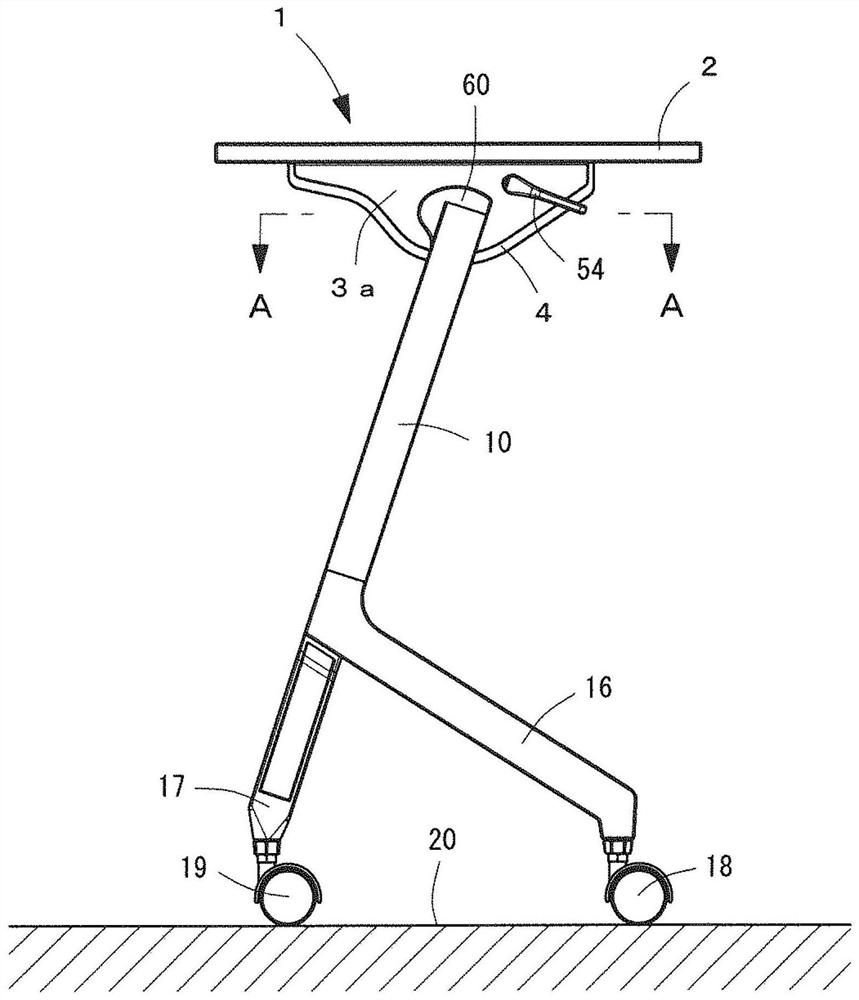

Folding table

InactiveCN111820588AAdjustable installation positionEasy to installFoldable tablesStowable tablesCamPhysics

The invention provides a folding table, which can simplify the structure, improve the appearance and improve the use safety, avoids complex welding, can be easily and reasonably manufactured, and caneasily and firmly fix a cam block and a supporting block on a rotating shaft which can rotatably support a table top and angle iron. Therefore, the folding action of the desktop can be stably and reliably carried out. The folding table is characterized in that angle iron (3) is fixed on the lower surface of a table top (2). A rotating shaft (6) is arranged in the angle iron (3), so that the angleiron (3) and the table top (2) are rotatably supported on the rotating shaft (6). A cam block (24) in which first and second cam grooves (32, 33) are formed is disposed in the angle iron (3). A lock cam (34) is rotatably disposed on the outside of the cam block (24). The locking cam (34) is engaged with the first and second cam grooves (32, 33). The cam block (24) is fixed to the rotating shaft (6).

Owner:HUIBIES FURNITURE

Space sport mixer

InactiveCN100462134CImprove mixing efficiencyIncrease load factorRotating receptacle mixersShaking/oscillating/vibrating mixersHelical lineUniversal joint

A space motion mixer comprises a crank arm, a rocking bar, a container frame, a mixing container, a machine frame, a speed reduction gearing, a motor, etc. The mixing container with a helical line-shape scraping blade therein is arranged inside the container frame, two ends of the container frame are mechanically connected to the crank arm via a ball pair and the rocking bar via a universal joint respectively, and the crank arm and the rocking bar are respectively connected with a rotary pair and the machine frame. When the crank arm rotates in a complete alternation, the rocking bar swings around the machine frame, and the mixing container has a space motion containing rotation and movement; because of the space quick return motion and helical curve scraping blade, the materials in the container can generate a three-D projecting motion along axial, radial and circumferential directions for driving materials to be in a conglomeration and diffusion motion alternately for thorough mixing to have a good mixing effect and a high mixing efficiency, additionally, the invention is provided with simple structure, and can be controlled conveniently and manufactured easily.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

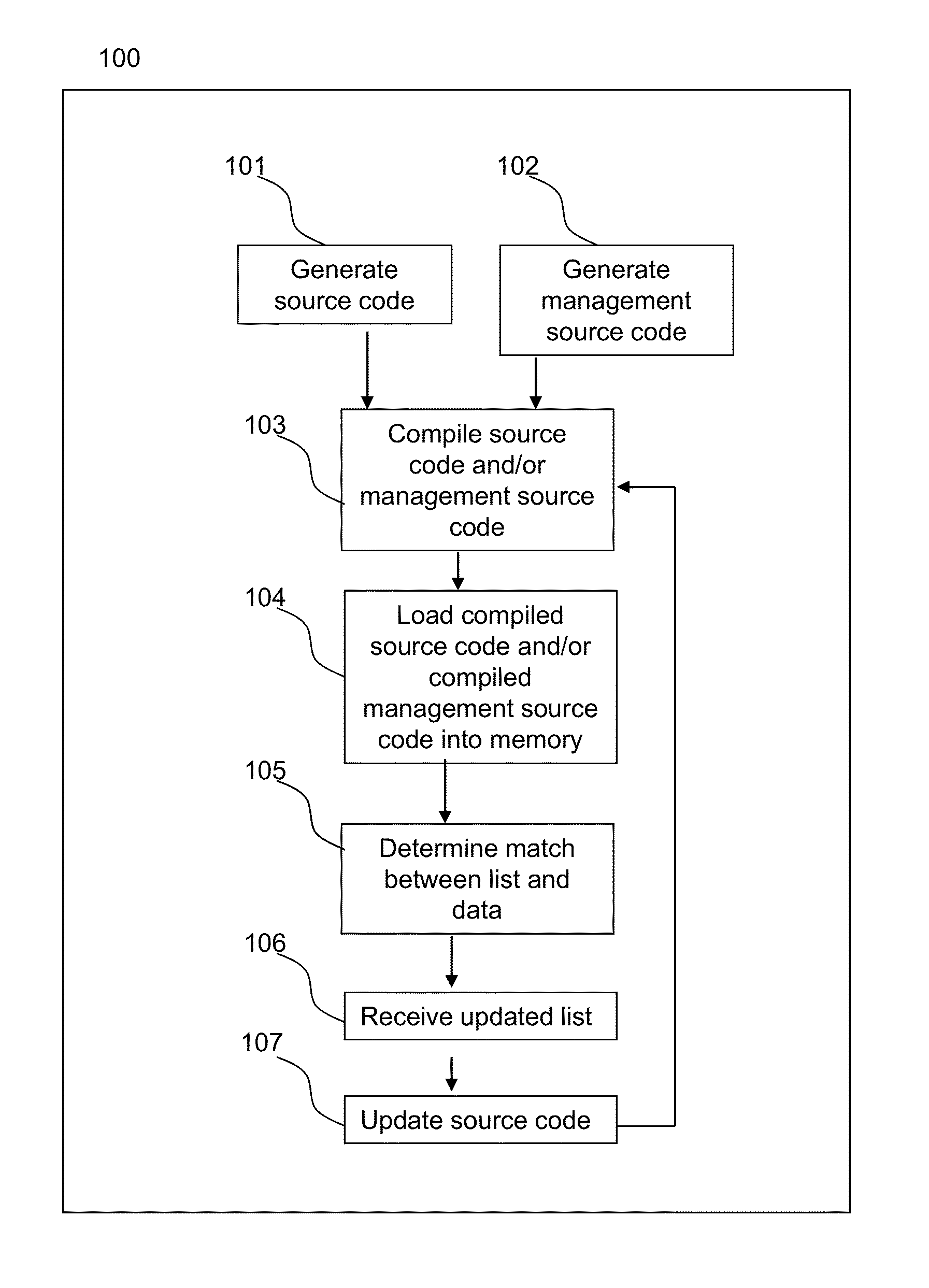

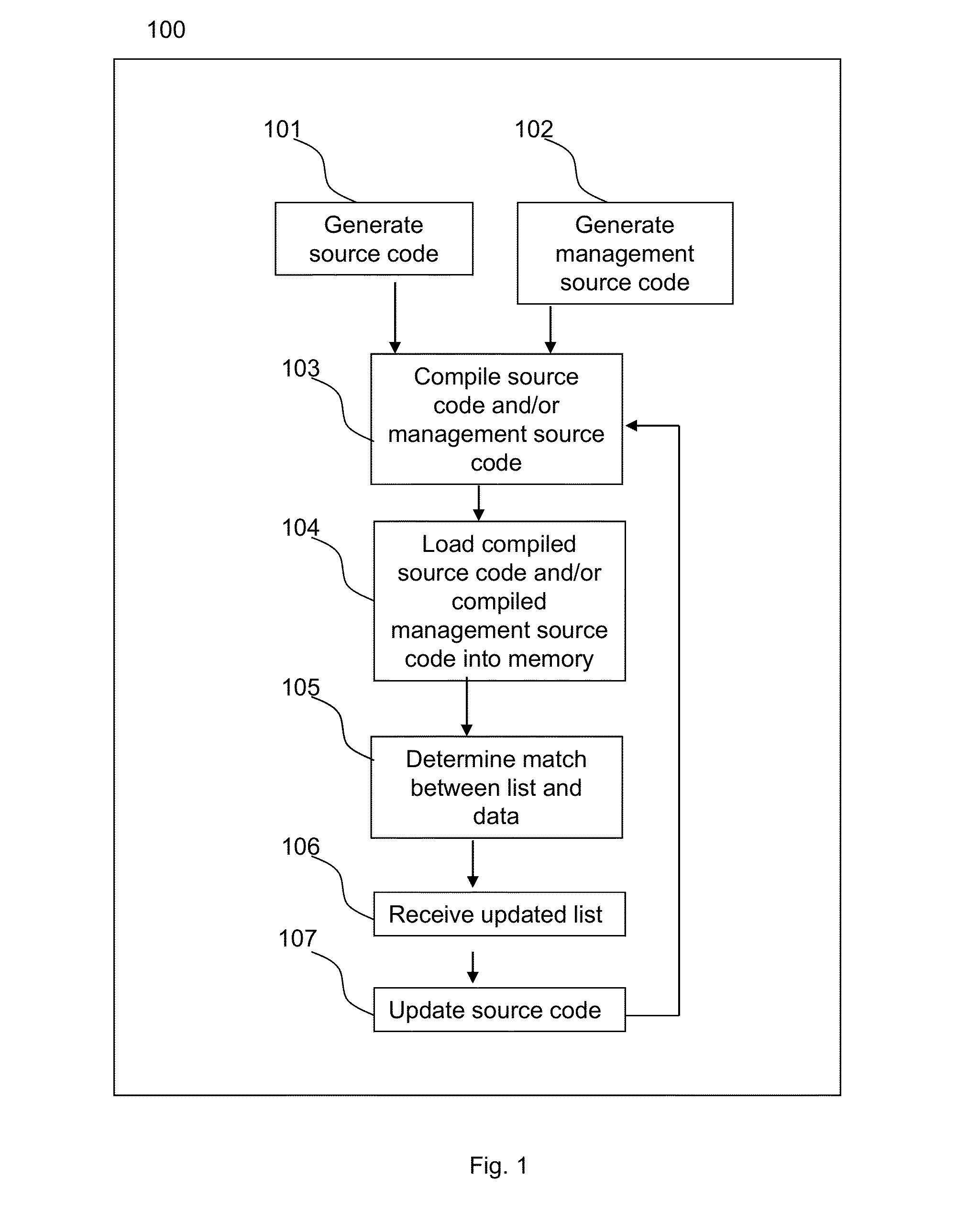

Matching an entry of a list to data

InactiveUS8595244B2Eliminate footprintEliminate overheadDigital data information retrievalDigital data processing detailsData matchingTheoretical computer science

A method, system and computer program product for matching an entry of a list to data. The method includes the steps of: generating source code which matches at least a part of said list with said data; compiling said source code into binary code; and determining a match between said list and said data using said compiled binary code wherein at least one of the steps is carried out using a computer device.

Owner:INT BUSINESS MASCH CORP

Automatic fast clamping bending die device for steel bar hoop bending machine

Owner:TJK MACHINERY TIANJIN

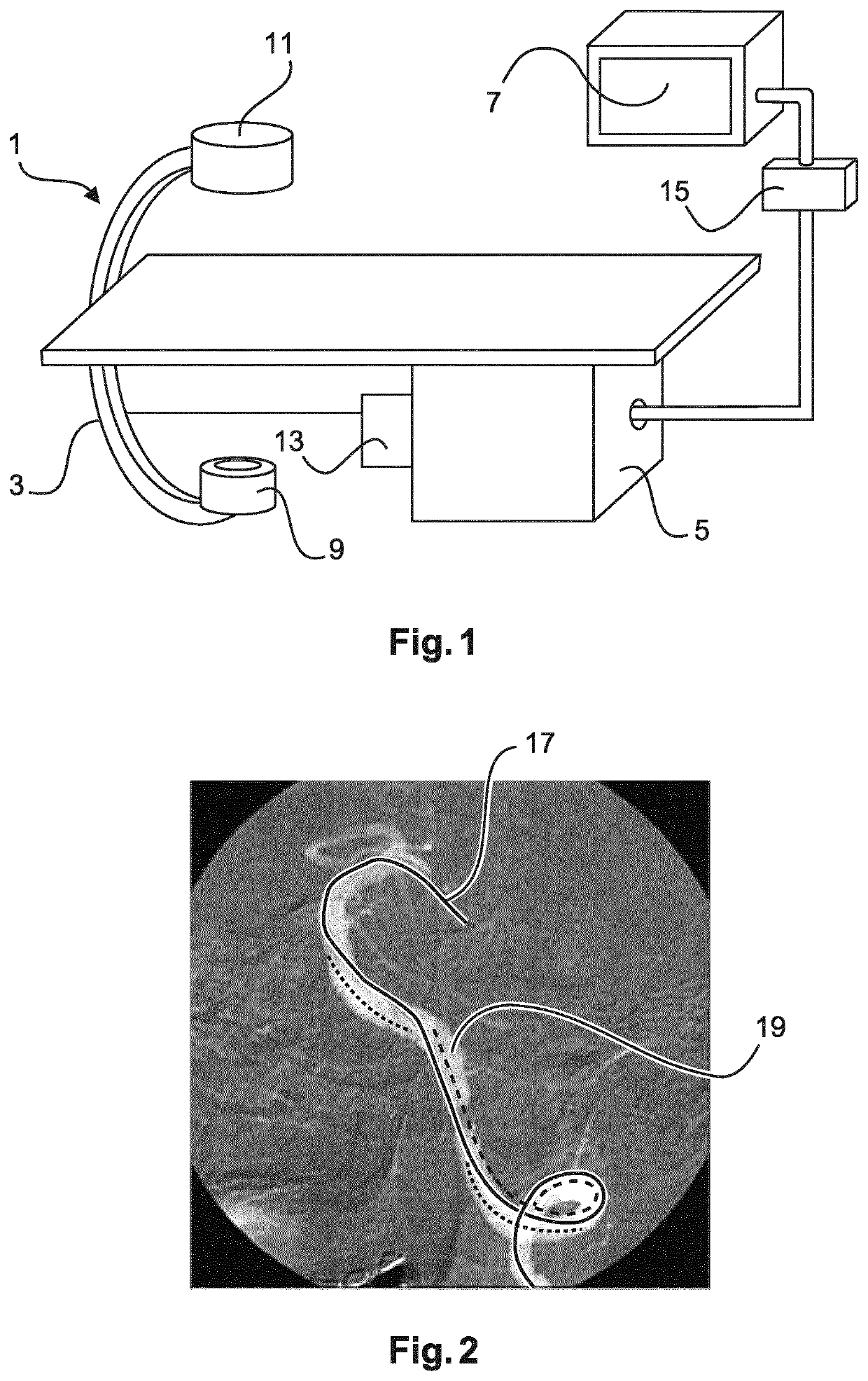

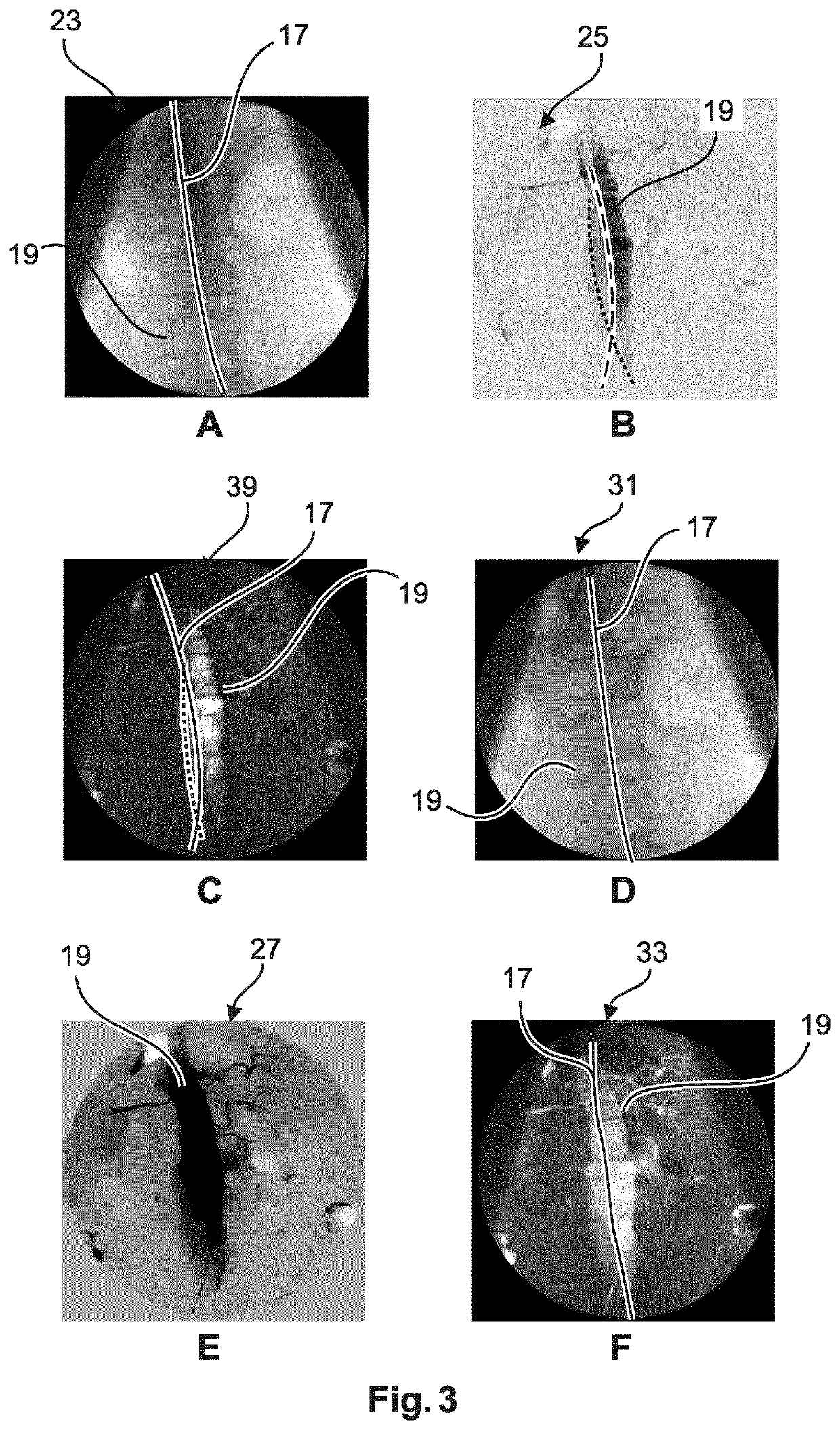

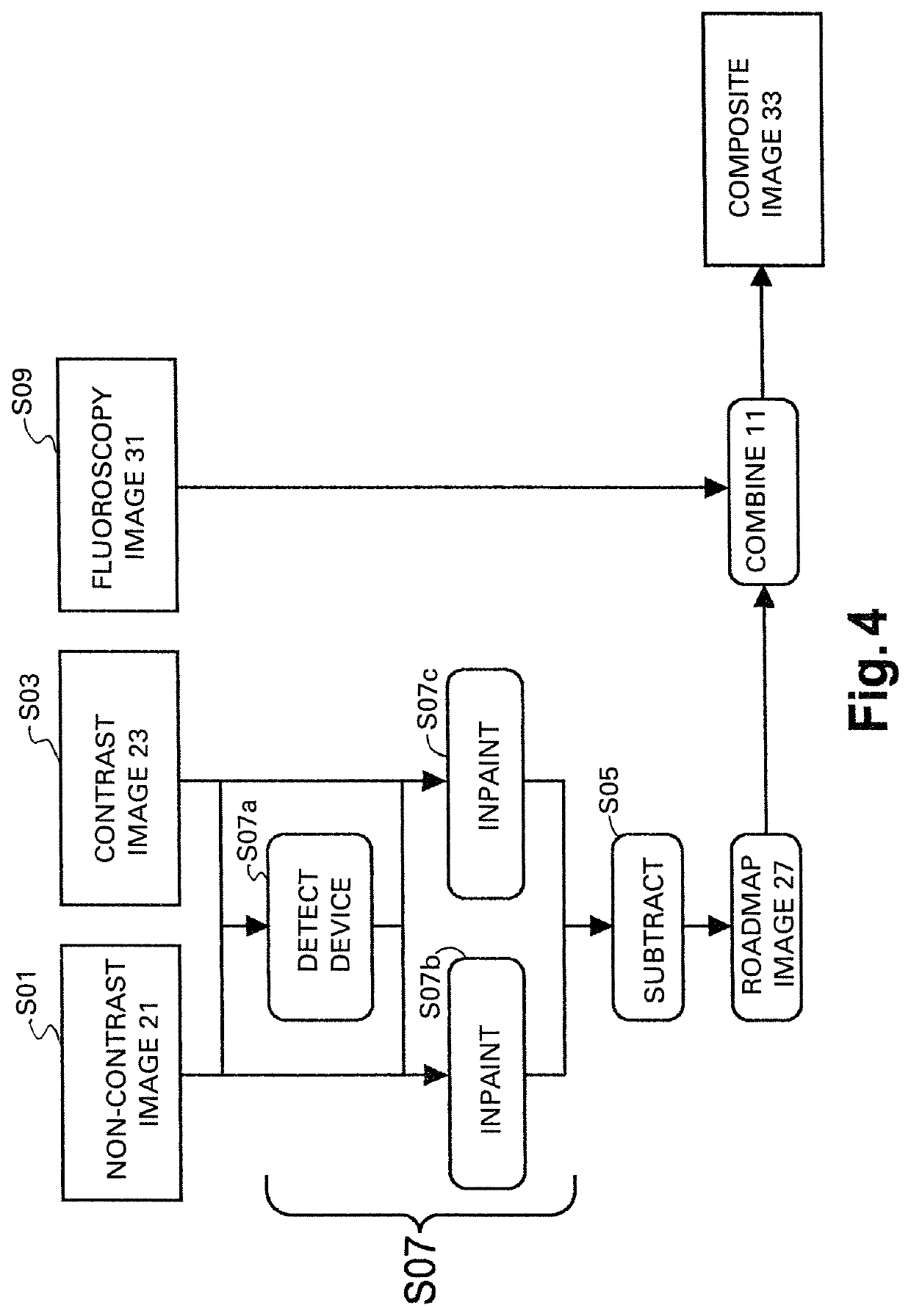

Automatic device-footprint-free roadmapping for endovascular interventions

ActiveUS10820874B2Improve visualizationMinimize visibilityPatient positioning for diagnosticsTomographyEndovascular interventionsComputer vision

A system (1) and a corresponding method enable an enhanced roadmapping visualization without unnecessary device-footprints. The system (1) includes an x-ray imaging device (3) for acquiring x-ray images and a calculation unit (5). The x-ray imaging device (3) is adapted for acquiring a first x-ray image (21) with an interventional device (17) present in the vessels (19) while no contrast agent is present in the vessels (19) and a second x-ray image (23) with the interventional device (17) present in the vessels (19) while contrast agent is present in the vessels (19). The calculation unit is adapted for creating a roadmap image (27) by subtracting the first x-ray image (21) from the second x-ray image (23) and automatically minimizing the visibility of the interventional device (17) in the roadmap image (27). A display unit (7) is adapted to display the roadmap image (27) or an overlay of a current fluoroscopy image (31) with the roadmap image (27).

Owner:KONINKLJIJKE PHILIPS NV

An easy-to-disassemble steel pipe motor assembly

ActiveCN107276284BFlexible installationImprove installation stabilityMagnetic circuit stationary partsSupports/enclosures/casingsEngineeringSteel tube

The invention discloses an easily-assembled and disassembled steel tube motor assembly, which comprises a shell and a mounting frame for external connection and fixing, wherein the axial end surface of the shell is provided with connection lugs for external connection of the end surface; the shell comprises a sleeve; the sleeve is internally provided with at least two arc magnets; thrust plates for tensioning and keeping the arc magnets apart are arranged between the circumferential end parts of the arc magnets; the inner wall of the sleeve is provided with assembling holes with thread; piercing holes are arranged in an interval area between the arc magnets; and fastening bolts in thread connection with the assembling holes are arranged in a penetrating mode on the circumferential surface of the sleeve supported by the mounting frame. The easily-assembled and disassembled steel tube motor assembly has the advantages of multiple auxiliary mounting, high mounting flexibility and good motor stability.

Owner:余姚市驰力电机有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com