Space sport mixer

A space movement and mixer technology, applied in the direction of mixers, jitter/oscillation/vibration mixers, mixers with rotating containers, etc., can solve problems such as slow speed, uneven mixing of materials, and reduced mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

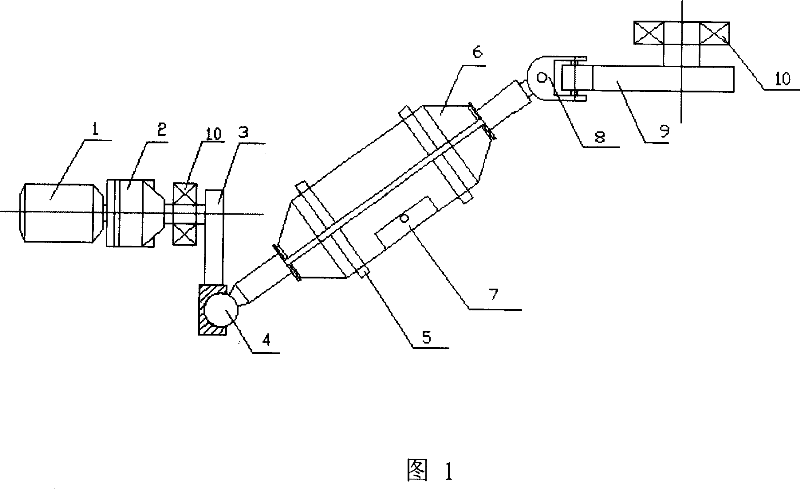

[0005] As shown in Figure 1, it can be used as one of the embodiments, the motor 1 makes the crank 3 rotate through the reduction device 2, and the mixing container 6 of the helical curve type "lifting board" is arranged in the cylinder and is installed in the container frame 5, and the discharge port is 7. One end of the container frame 5 is mechanically connected with the crank 3 by the ball pair 4, and the other end is connected with the universal joint 8 and the rocker 9, and the rocker 9 and the crank 3 are respectively connected with the frame 10 by the hinge rotation pair, and their The axes of rotation are perpendicular to each other, or they may not be arranged vertically. When the crank 3 rotates continuously, there is a quick return motion in the space mechanism, and any point on the mixing container generates a space trajectory, and the material in the container moves along with the container, which includes both translation and rotation with a large acceleration. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com