Miniaturized substrate integration waveguide duplexer

A substrate-integrated waveguide and duplexer technology, which is applied to waveguide-type devices, electrical components, circuits, etc., can solve the problems of high processing cost, large duplexer volume, and difficulty in integration, and achieves fast processing cycle and eliminates area. , easy-to-integrate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

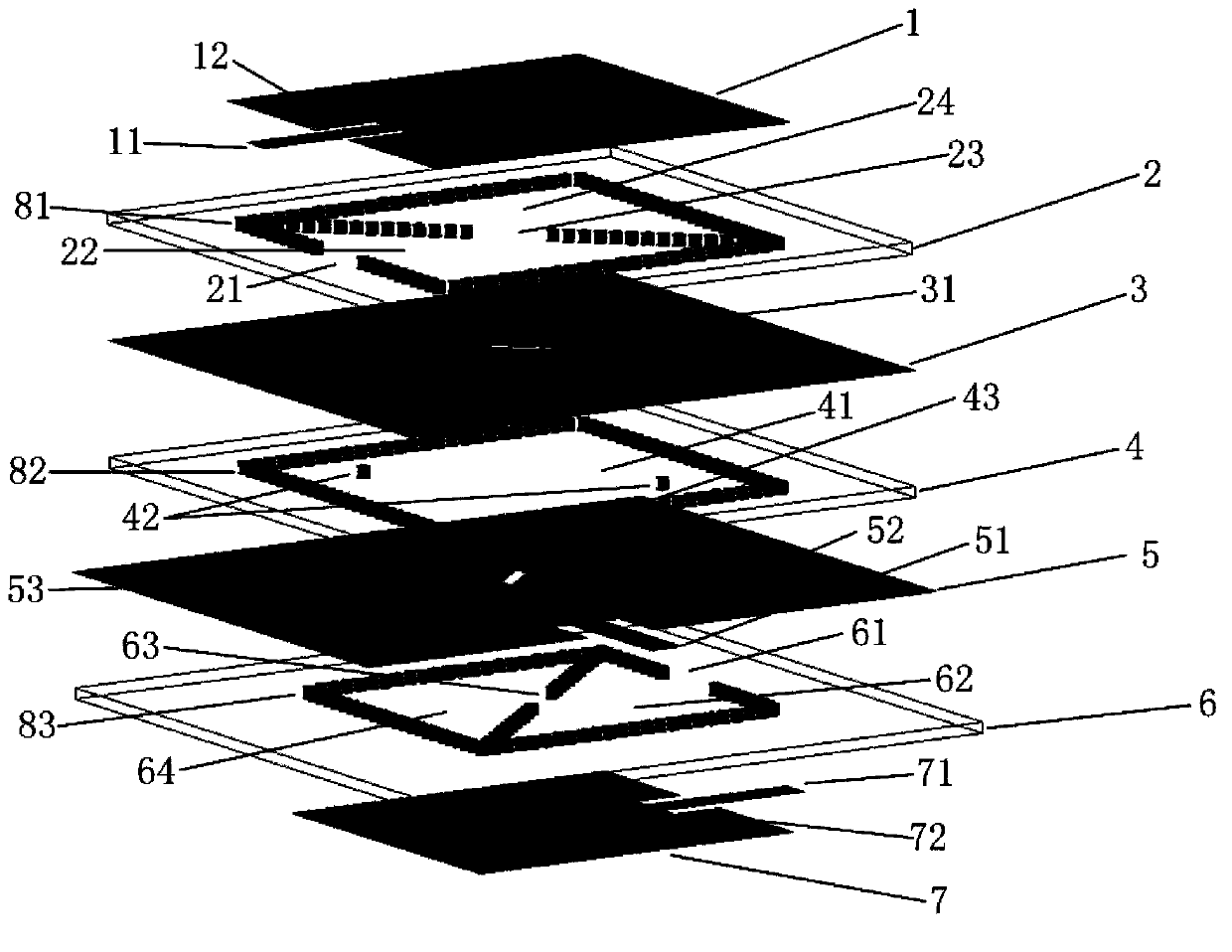

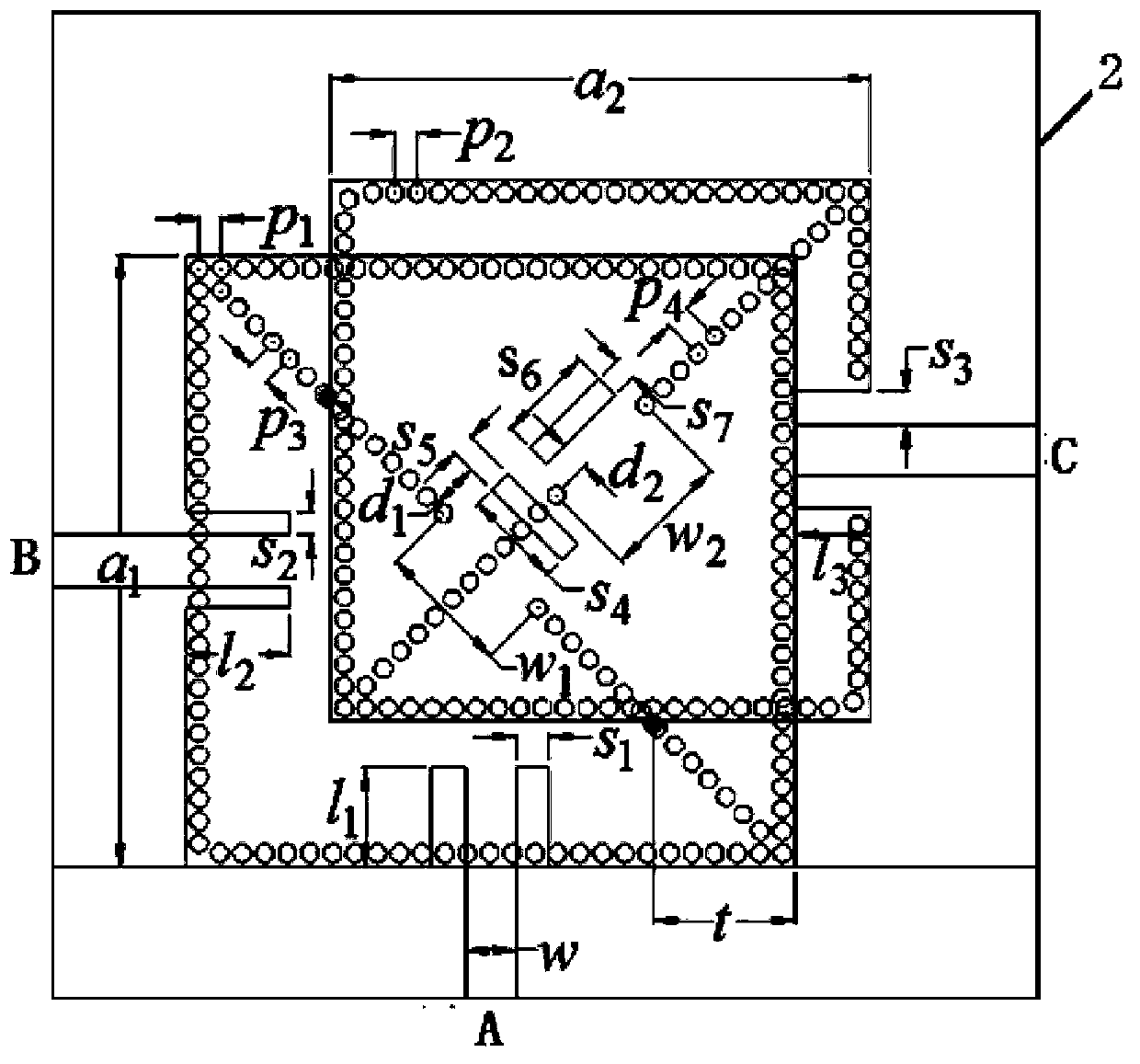

[0013] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment: figure 1 As shown, the miniaturized substrate-integrated waveguide duplexer is characterized in that it includes a first metal copper clad layer 1, a first dielectric layer 2, a second metal copper clad layer 3, and a second dielectric layer stacked sequentially from top to bottom. Layer 4, the third metal copper clad layer 5, the third dielectric layer 6, the fourth metal copper clad layer 7; the metallized through hole array 81 runs through the first metal copper clad layer 1, the first dielectric layer 2, the second metal clad layer The second metal clad copper layer 3 forms a triangular resonant cavity 1 22 and a triangular resonant cavity 2 24 of the same size. These two triangular resonant cavities are isosceles right triangles; Metallized through-holes 42 penetrate the second metal copper-clad layer 3, the second dielectric layer 4, and the thir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| isolation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com