A cyclone combustion boiler advanced air staged combustion denitrification system and method

An air staging and cyclone combustion technology, applied in the combustion method, the fuel burned in the melted state, the combustion type, etc., can solve the problems of increasing the difficulty of ammonia escape control, increasing the catalyst and reducing agent, and improving the emission limit level, etc. Overcome the effects of low denitration efficiency, elimination of catalyst use, and high denitration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

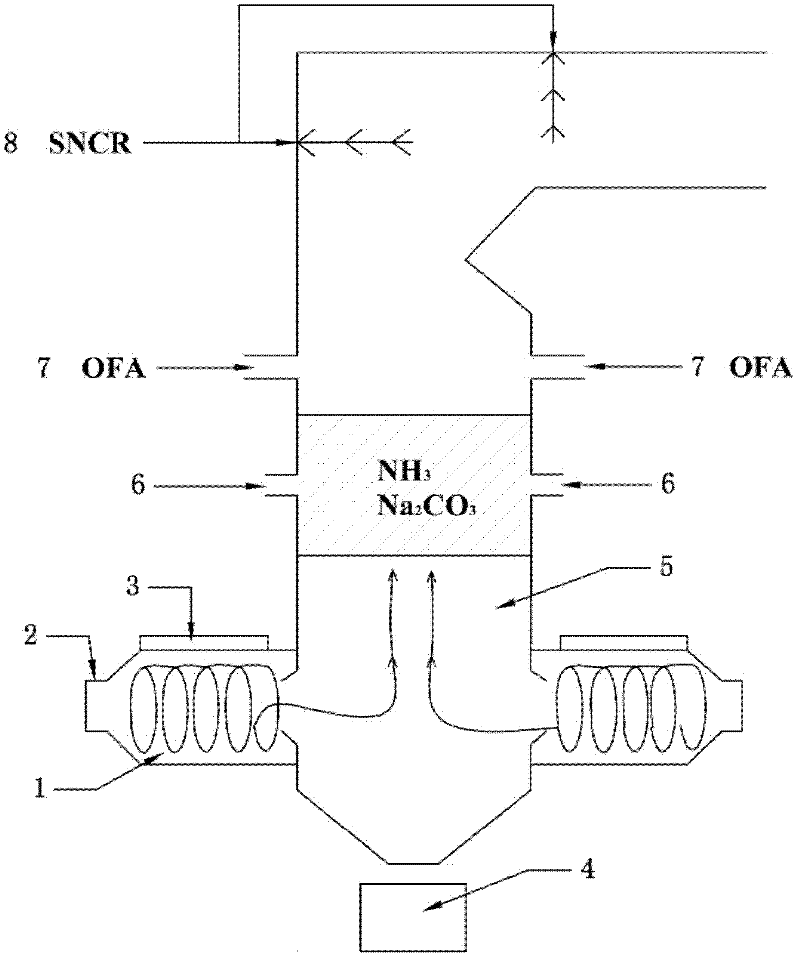

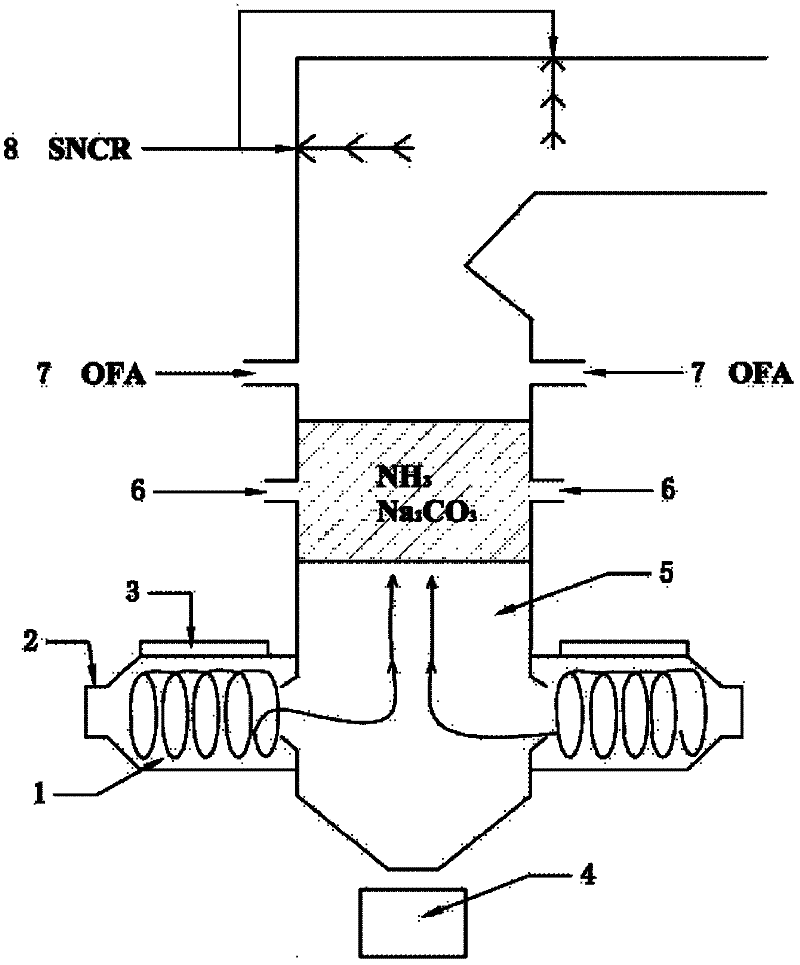

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

[0025] see figure 1 , a cyclone combustion boiler advanced air staged combustion denitrification method and system proposed by the present invention, specifically refers to:

[0026] (1) The fuel air flow sent into the cyclone from the primary air inlet is strongly mixed with the secondary air sent into the secondary air inlet, and then burned under the condition of excess air coefficient αx The flue gas has an excess air coefficient α of about 0.6 to 0.95. In the specific implementation process, according to the characteristics of actual coal combustion, the secondary air inlet can be fed with "oxygen-enriched" air (that is, air with an oxygen concentration greater than 21%) according to needs, so as to overcome the conventional air classification of cyclone combustion boilers. Compared with the normal combustion conditions, the combustion temperature in the cyclone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com