Automatic quick bending-die clamping device of reinforcement hoop bending machine

A steel bar bending hoop and bending technology, applied in the field of steel bar hoop bending machine, can solve the problems of low product quality and production efficiency, high labor intensity of operators, unsafe mold replacement, etc., to improve processing efficiency, save procedures, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

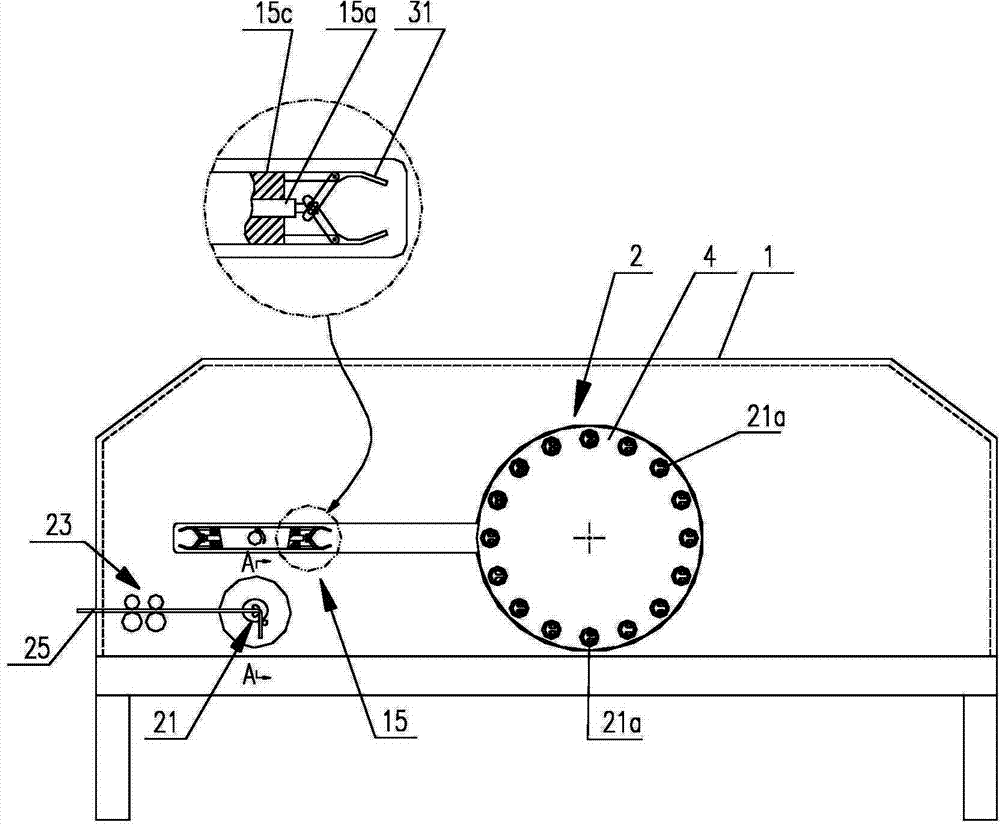

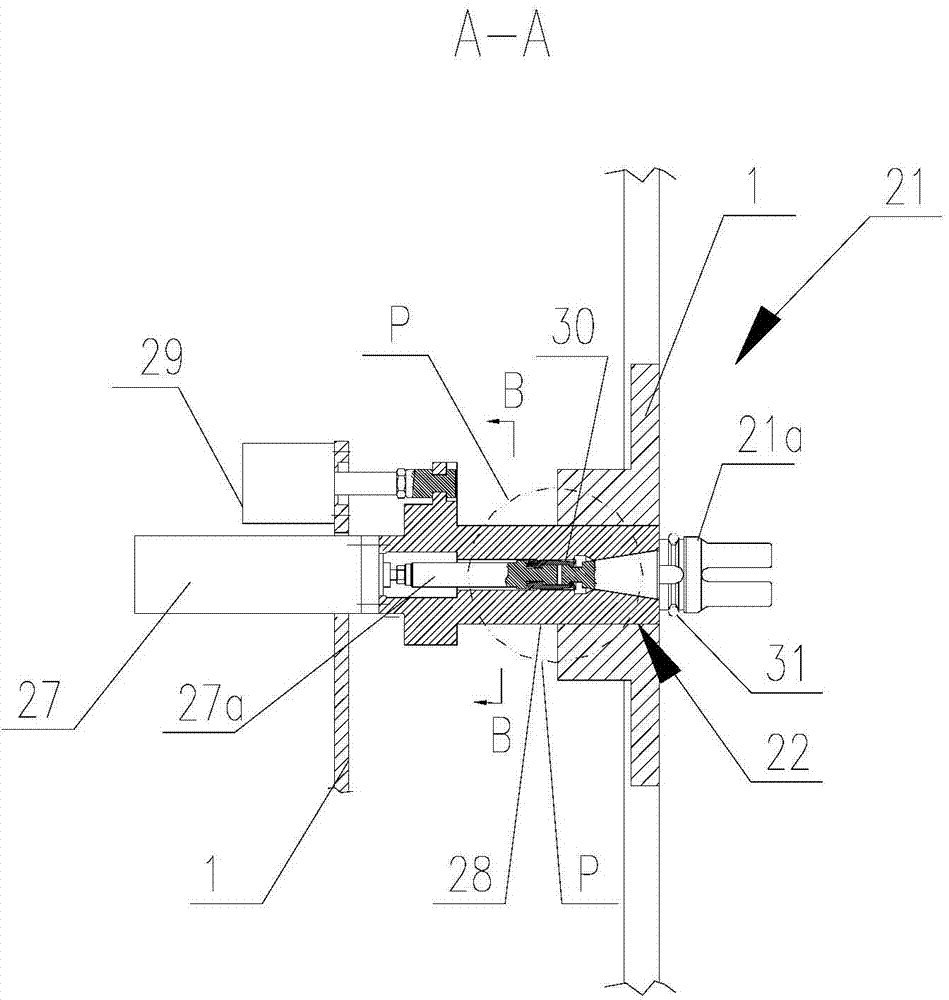

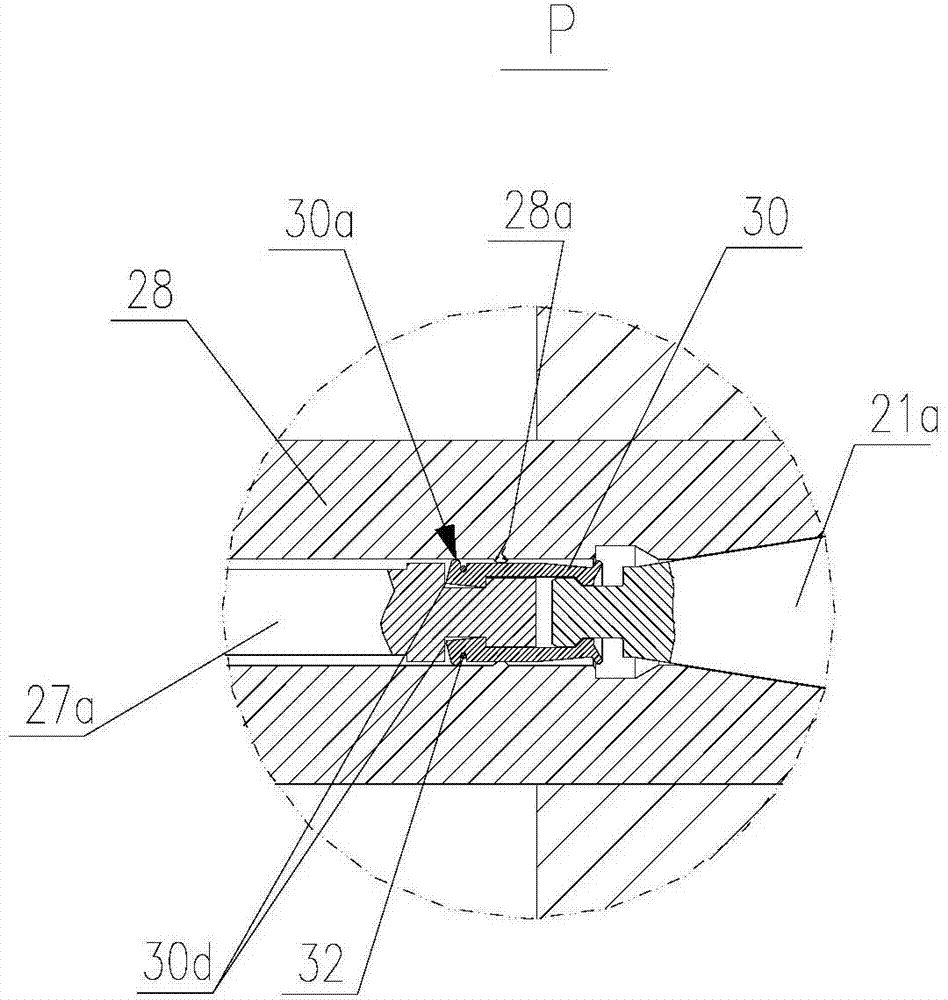

[0030] As shown in the figure, the present invention provides an automatic fast clamping bending mold device for a steel bar hoop bending machine. The automatic fast clamping bending head device includes: a frame 1 of a steel bar hoop bending machine, a bending machine head 21, and It includes a mold library 2 and a manipulator 15 arranged in the through hole of the frame 1 panel on one side of the bending machine head 21 .

[0031] A plurality of curved molds 21a with different specifications are installed on the outer surface of the mold turntable 4 in the mold library 2, and the mold turntable 4 is connected to a rotating mechanism that drives its rotation and a reciprocating movement mechanism that extends / retracts along its axis; the manipulator 15 It has an extension / retraction reciprocating movement mechanism and a rotation mechanism that automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com