Baked type Xinyang Maojian tea and processing technology thereof

A Xinyang Maojian and processing technology, which is applied in the field of baked Xinyang Maojian and its processing technology, can solve the problems of mixed soup, weak taste, small buds and leaves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

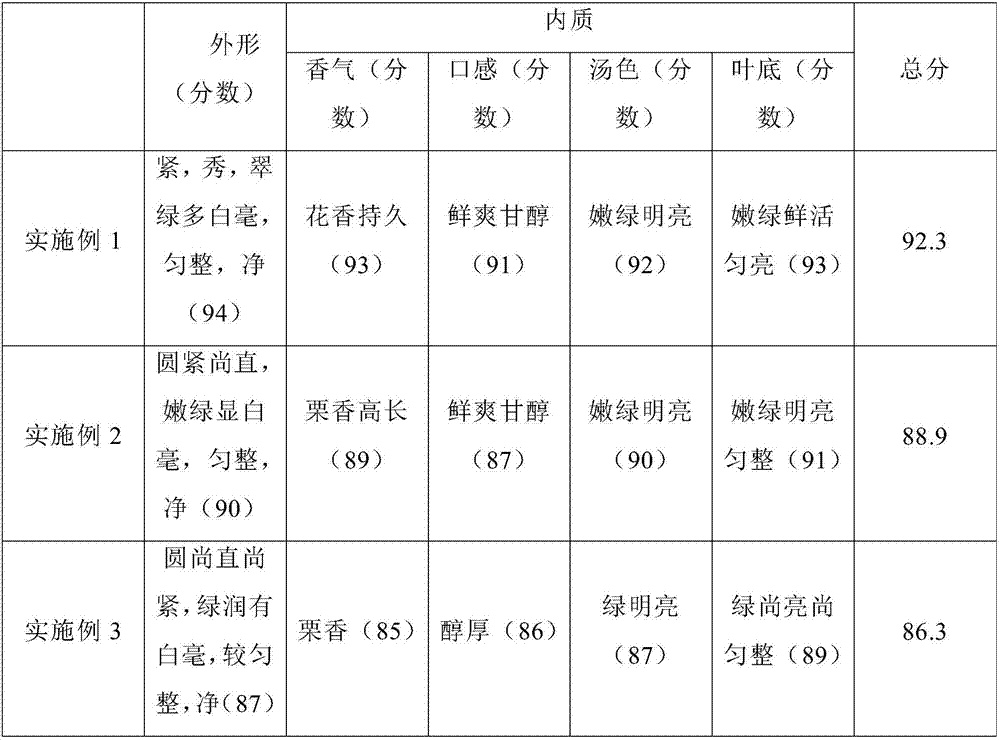

Embodiment 1

[0023] A baking type Xinyang hair tip processing technology, which comprises the following steps:

[0024] Grading: Classify Xinyang Maojian fresh leaves according to picking standards, and separate Xinyang Maojian fresh leaves with one bud and half leaf, one bud and one leaf, and one bud and two leaves;

[0025] For cleaning, a bubble cleaning machine is used to clean the Xinyang Maojian fresh leaves with one bud and a half. After cleaning, the Xinyang Maojian fresh leaves are placed on a vibrating track to ventilate and dry the surface moisture to obtain clean Xinyang Maojian fresh leaves. ;

[0026] Fixing: Under the conditions of 220°C and infrared light, put the clean fresh leaves of Xinyang Maojian in the fixing bamboo tank for 3 minutes to get the fixing leaves with a moisture content of 23%;

[0027] Knead and first place described green leaves on the airing sieve and spread out until the thickness is 12cm to carry out airing and remoistening treatment, the water cont...

Embodiment 2

[0031] A baking type Xinyang hair tip processing technology, which comprises the following steps:

[0032] Grading: Classify Xinyang Maojian fresh leaves according to picking standards, and separate Xinyang Maojian fresh leaves with one bud and half leaf, one bud and one leaf, and one bud and two leaves;

[0033] Cleaning Using a bubble cleaner to clean the Xinyang Maojian fresh leaves with one bud and one leaf, the cleaned Xinyang Maojian fresh leaves are placed in a washing bucket to remove surface moisture to obtain clean Xinyang Maojian fresh leaves;

[0034] Fixing: Under the conditions of 250°C and infrared light, put the clean Xinyang Maojian fresh leaves in the fixing bamboo tank for 1.5 minutes to get the fixing leaves with a moisture content of 20%;

[0035] Kneading: first spread out the de-enzyming leaves in the airing sieve until the thickness is 8cm and remoisturize. After re-wetting, the moisture content of the de-enzyme leaves is 24%; then carry out kneading tr...

Embodiment 3

[0039] A baking type Xinyang hair tip processing technology, which comprises the following steps:

[0040] Grading: Classify Xinyang Maojian fresh leaves according to picking standards, and separate Xinyang Maojian fresh leaves with one bud and half leaf, one bud and one leaf, and one bud and two leaves;

[0041] Cleaning Using a bubble cleaner to clean the Xinyang Maojian fresh leaves with one bud and two leaves, the cleaned Xinyang Maojian fresh leaves are placed in a washing bucket to remove surface moisture to obtain clean Xinyang Maojian fresh leaves;

[0042] Fixing: Under the conditions of 223°C and infrared light, put the clean Xinyang Maojian fresh leaves in the fixing bamboo tank for 2 minutes to get the fixing leaves with a moisture content of 22%;

[0043] Kneading: first spread the de-enzyming leaves to a thickness of 10cm for remoistening, after re-wetting, the moisture content of the de-enzyming leaves is 24%; then kneading treatment for 20min, to obtain the kne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com