Adjustable type wire cutting machining roller

A wire cutting and adjustable technology, applied in electric processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing installation and adjustment steps, inconvenient promotion and use, and increasing production costs, so as to improve accuracy and increase thickness. , the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

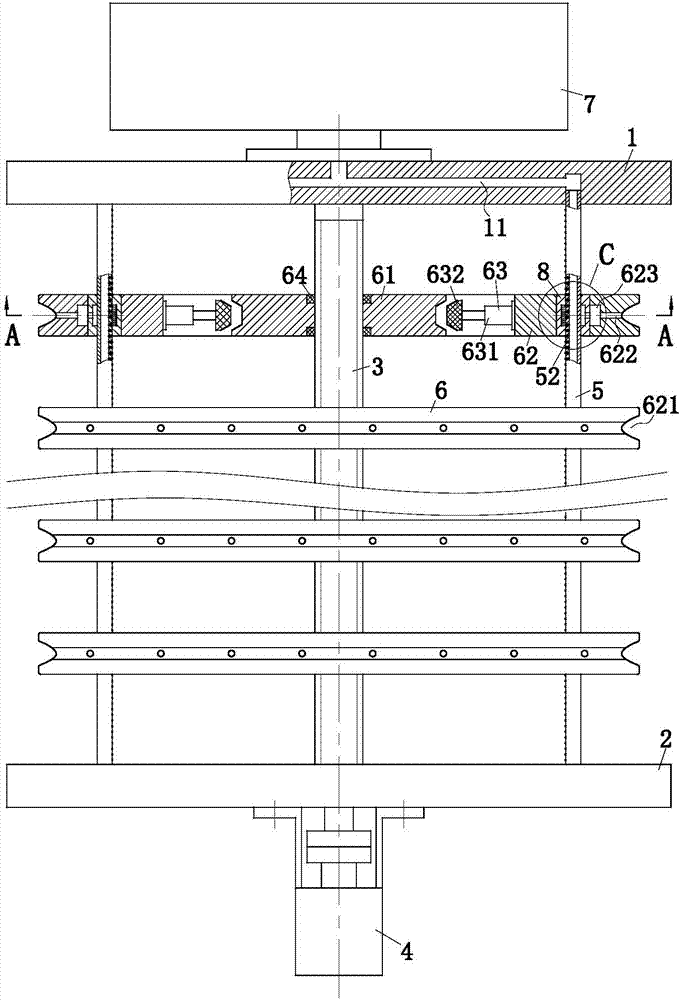

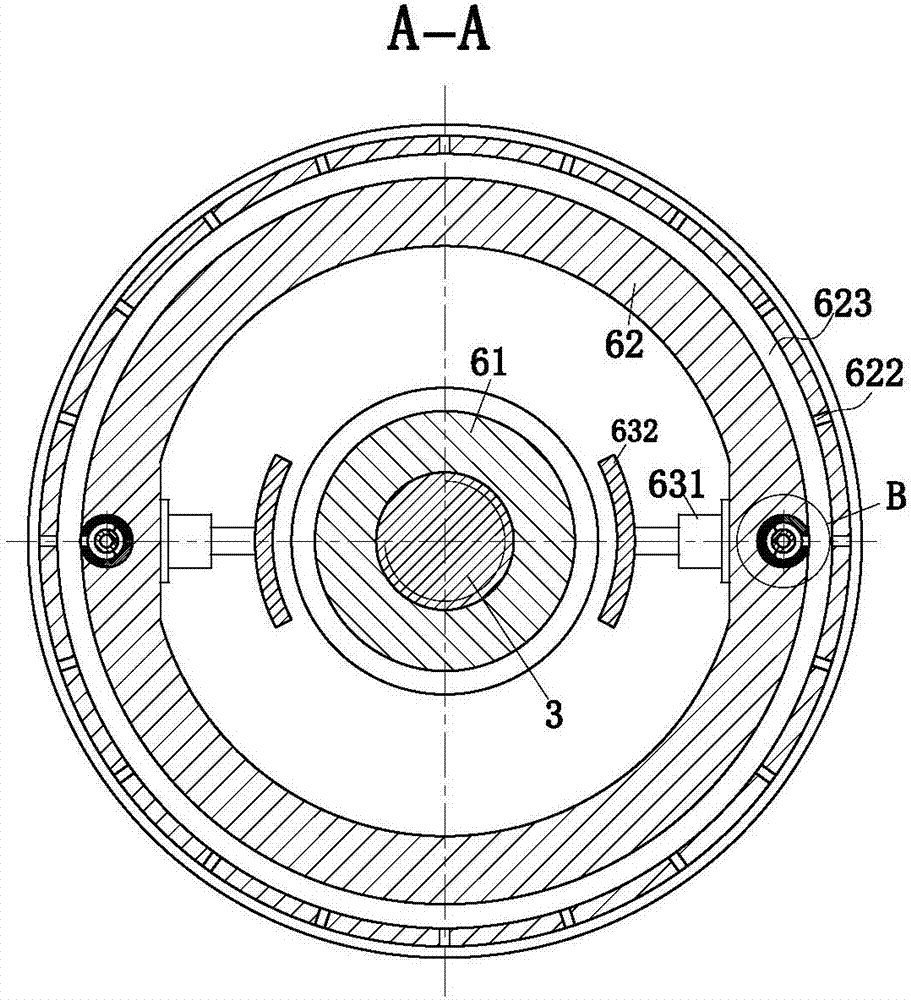

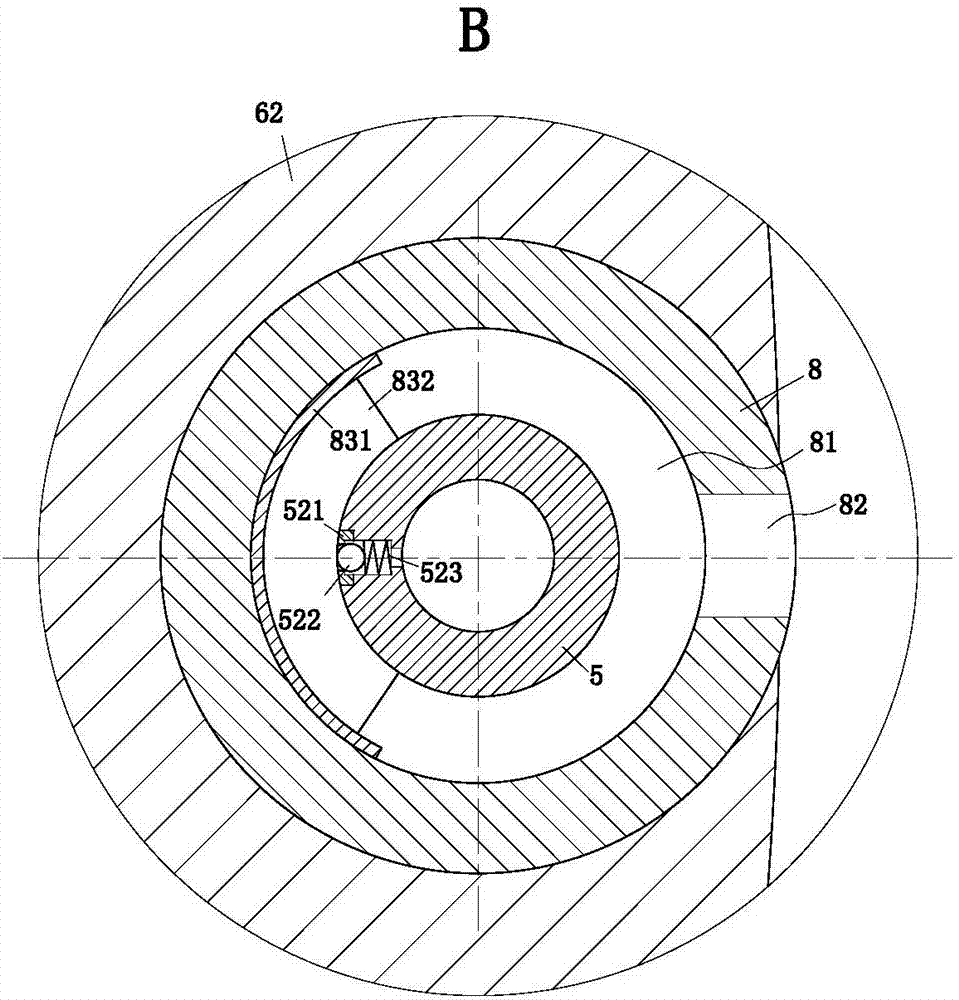

[0031] As an embodiment of the present invention, the guide rod 5 is a hollow rod, and the guide rod 5 is equidistantly provided with a plurality of water outlet holes 51 along its own length direction, and a pressing module 52 is installed in the water outlet hole 51, and the pressing module 52 is used for Discharge the coolant located in the guide rod 5. When the press module 52 is pressed, the coolant will be discharged from the water outlet hole 51. When the press module 52 is not pressed, the press module 52 will block the water outlet hole 51, and the coolant will be will not flow out; the fixed plate 1 is provided with a cooling channel 11, and the cooling channel 11 introduces the cooling liquid from the center of the fixed plate 1 into the guide rod 5; the bottom of the guide groove 621 of the guide wheel 62 is provided with a plurality of Cooling holes 622, a plurality of cooling holes 622 are evenly arranged along the circumferential direction of the guide wheel 62, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com