Light guide arm used for laser shock wave technology

A technology of shock wave and light guide arm, applied in the field of light guide arm, can solve the problems of poor flexibility and low efficiency, achieve the effect of convenient installation and disassembly, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, specific implementations are now described in detail.

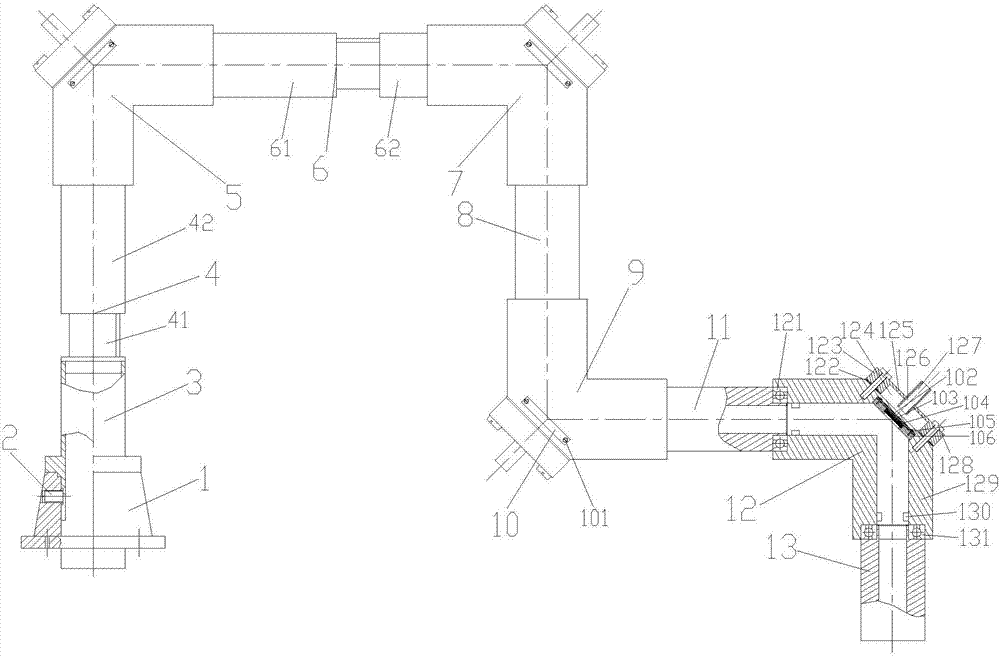

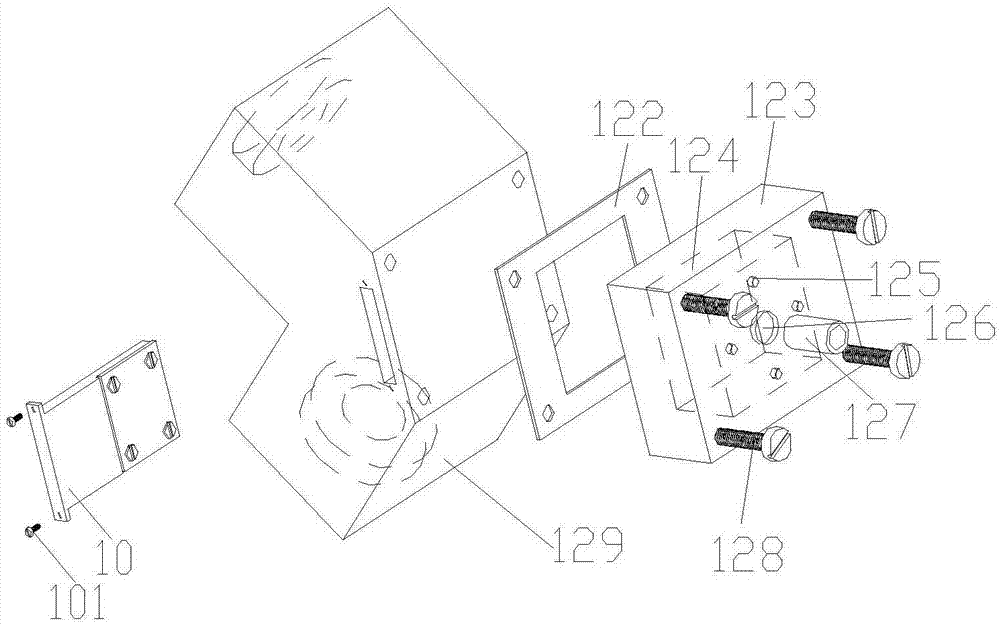

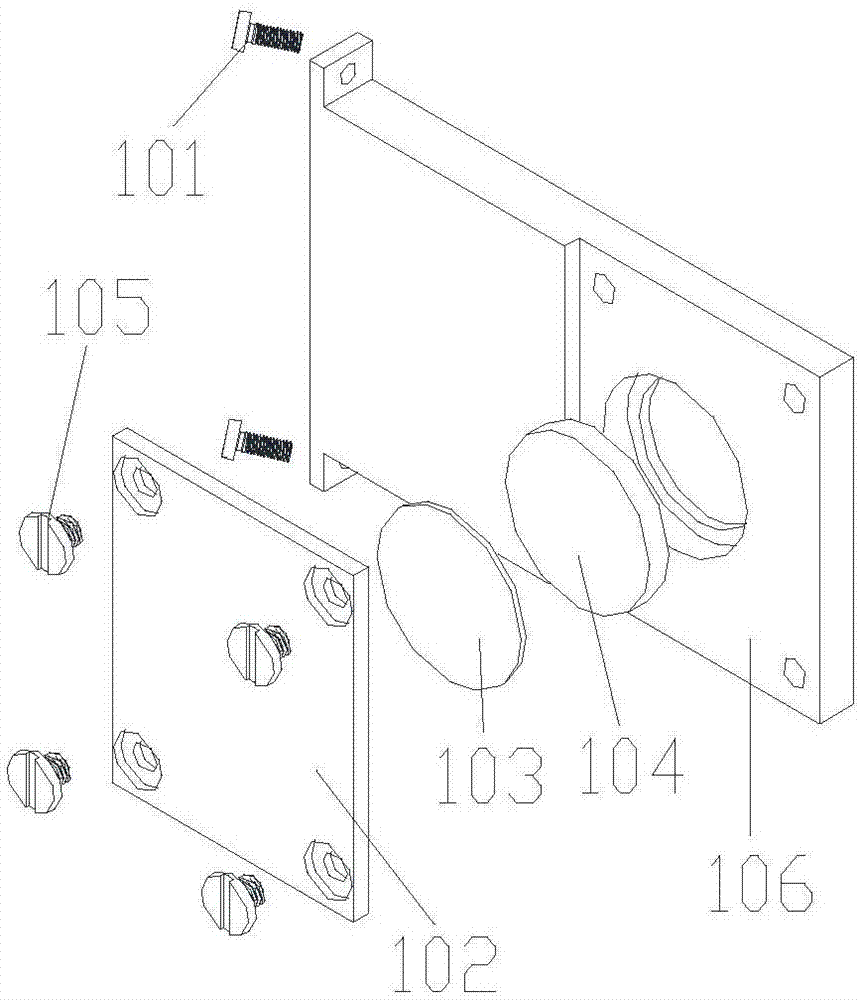

[0032] Such as Figure 1~3 As shown, the light guide arm for laser shock wave technology, including:

[0033] Base 1 for receiving laser light, connected with external equipment;

[0034] The base connecting pipe 3 for transmitting the optical path is fixedly connected with the base 1 through the fastening screw 2, and is fixedly connected with the longitudinal first telescopic pipe 41 of the longitudinal telescopic pipe 4 for increasing the processing range;

[0035] The first articulated arm 5 used for laser transmission is fixedly connected to the second longitudinal telescopic tube 42 of the longitudinal telescopic tube 4 through the first bearing, and is fixedly connected to the first horizontal telescopic tube 61 of the horizontal telescopic tube 6 through the second bearing;

[0036] The secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com