Fuel pump automatic assembly line and operating method thereof

A fuel pump and assembly line technology, which is applied to the automatic assembly line of fuel pumps and its operation field, can solve the problems of low efficiency of manual assembly, low adaptability, and inability to improve accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

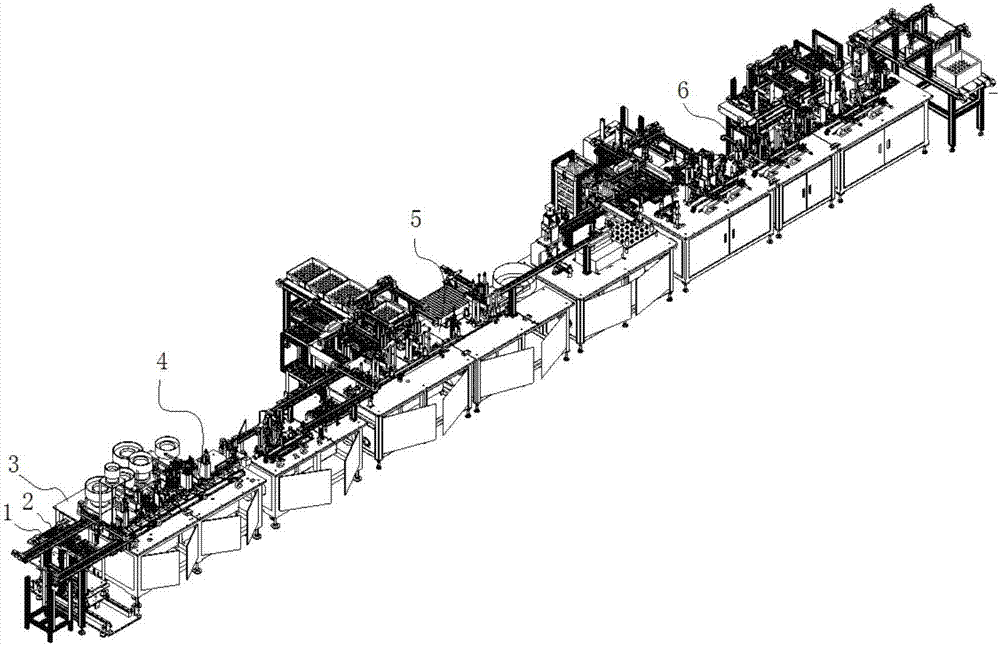

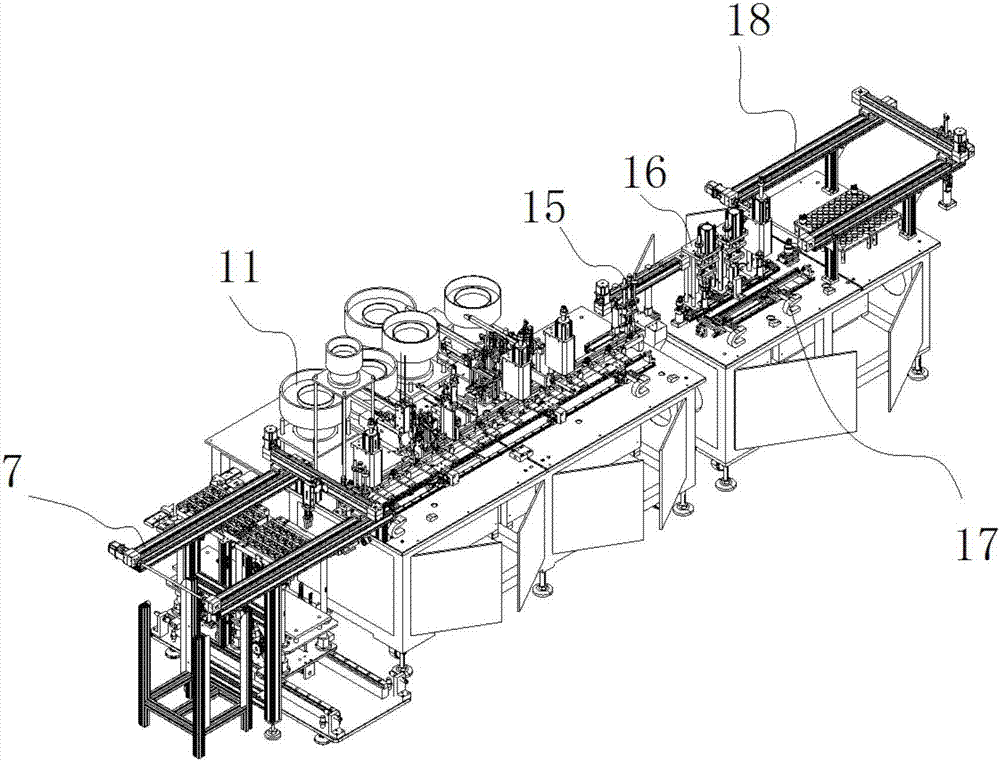

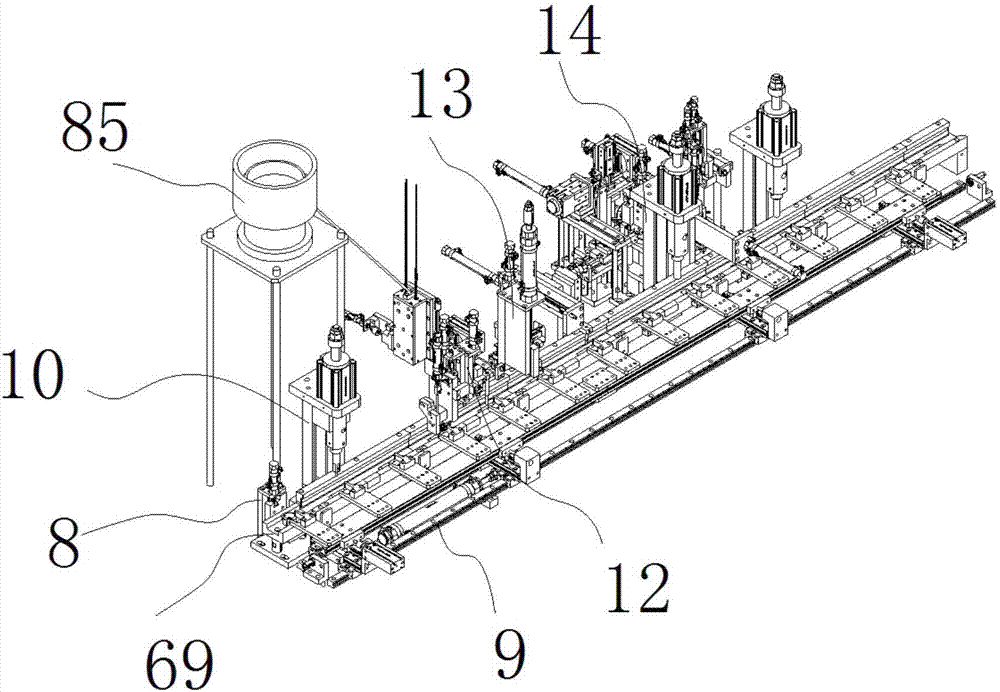

[0387] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 , Figure 22 , Figure 23 , Figure 24 , Figure 25 , Figure 26 , Figure 27 , Figure 28 , Figure 29 , Figure 30 , Figure 31 , Figure 32 , Figure 33 , Figure 34 , Figure 35 , Figure 36 , Figure 37 , Figure 38 , Figure 39 , Figure 40 , Figure 41 , Figure 42 , Figure 43 , Figure 44 , Figure 45 , Figure 46 , Figure 47 , Figure 48 , Figure 49 , Figure 50 , Figure 51 , Figure 52 , Figure 53 , Figure 54 , Figure 55 , Figure 56 , Figure 57 , Figure 58 , Figure 59 , Figure 60 , Figure 61 , Figure 62 , Figure 63 , Figure 64 , Figure 65 , Figure 66 , Figure 67 , Figure 68 , Figure 69 , Figure 70 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com