Glass feeding and discharging device for glass edge grinding machine

A glass edging and edging machine technology, which is applied to machine tools suitable for grinding workpiece edges, parts of grinding machine tools, grinding machines, etc., can solve problems affecting production efficiency and difficult handling, and achieve simple structure and easy promotion And the effect of novelty in use and design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

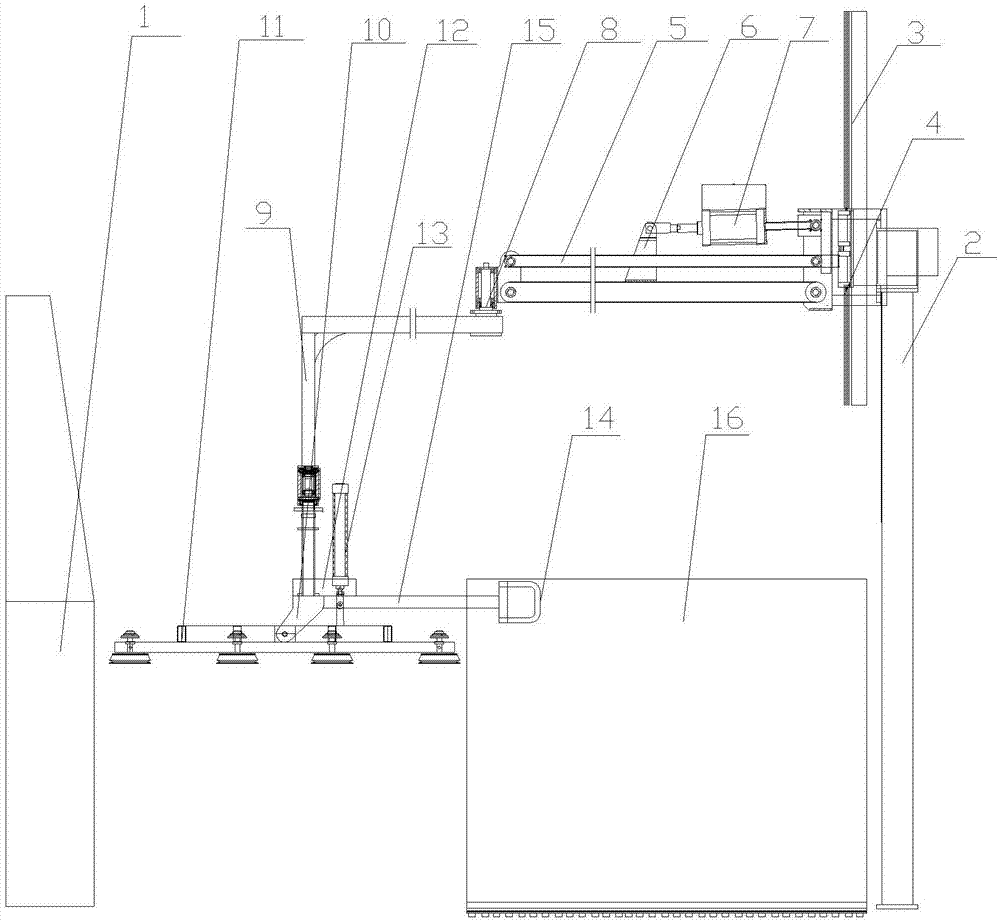

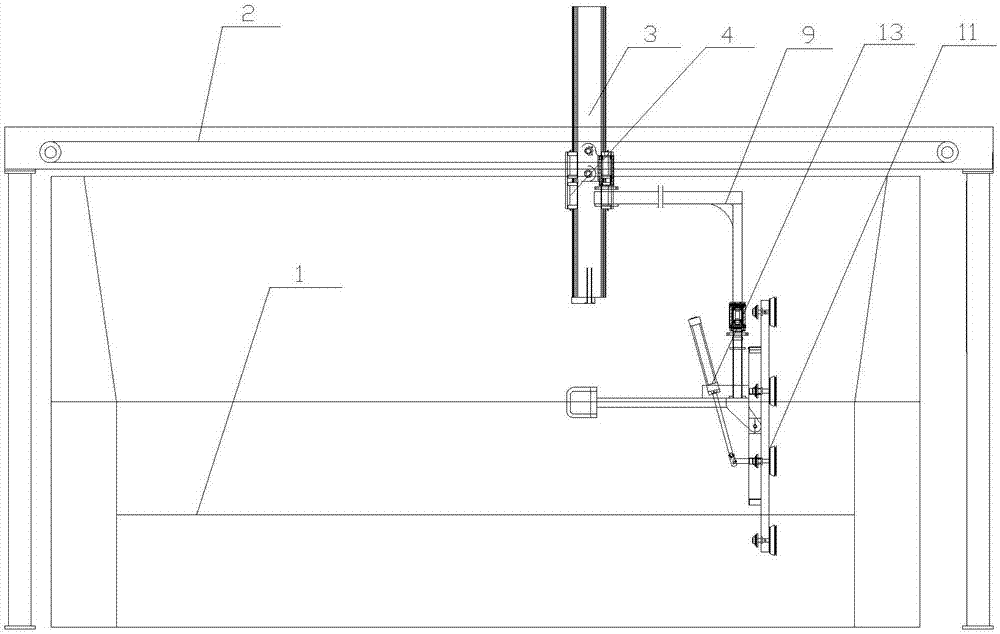

[0018] Such as figure 1 , figure 2 As shown, a glass loading and unloading device for glass edging machine, the front end of the glass edging machine 1, the main body is a gantry 2, and the vertical guide rail 3 that is arranged on the top of the gantry 2 and can move laterally A ferrule 4 that can move up and down on the vertical guide rail 3 is installed on the vertical guide rail 3. A crossbeam 5 that is movably connected with the ferrule 4 is installed on the ferrule 4. The top of the ferrule 4 and the middle part of the crossbeam 5 are all provided with Ear plates 6, and a jacking cylinder 7 is movably connected between the two ear plates 6, a shaft 8 is installed at the end of the beam 5, and an angular shaft 9 that can rotate around the shaft 8 is set on the supporting shaft 8, and the bottom of the angular shaft 9 is Connected with an angled plate 10, a glass suction cup 11 is installed on the angled plate 10, a positioning plate 12 is arranged between the angled pla...

Embodiment 2

[0020] Such as figure 1 , figure 2 As shown, a glass loading and unloading device for glass edging machine, the front end of the glass edging machine 1, the main body is a gantry 2, and the vertical guide rail 3 that is arranged on the top of the gantry 2 and can move laterally A ferrule 4 that can move up and down on the vertical guide rail 3 is installed on the vertical guide rail 3. A crossbeam 5 that is movably connected with the ferrule 4 is installed on the ferrule 4. The top of the ferrule 4 and the middle part of the crossbeam 5 are all provided with Ear plates 6, and a jacking cylinder 7 is movably connected between the two ear plates 6, a shaft 8 is installed at the end of the beam 5, and an angular shaft 9 that can rotate around the shaft 8 is set on the supporting shaft 8, and the bottom of the angular shaft 9 is Connected with an angled plate 10, a glass suction cup 11 is installed on the angled plate 10, a positioning plate 12 is arranged between the angled pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com