Automatic slicing mechanism for strip-shaped vegetables and fruits

A fruit and vegetable, slicing technology, applied in metal processing and other directions, can solve the problems of cumbersome mechanism, low cutting efficiency, inability to achieve complete cutting, etc., to achieve the effect of uncomplicated structure and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

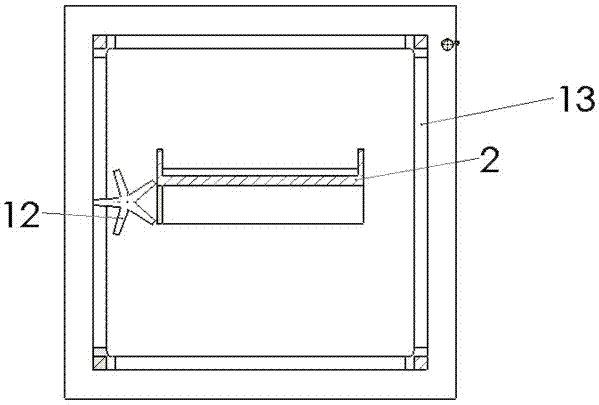

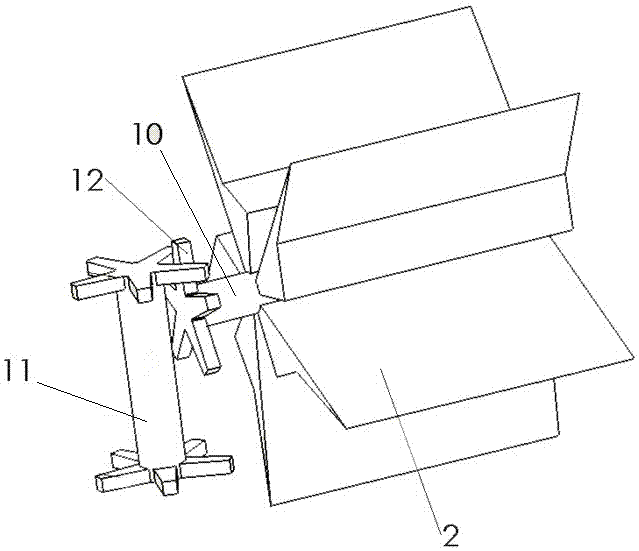

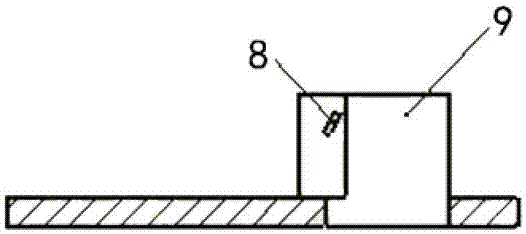

[0020] As shown in the figure: a strip-shaped fruit and vegetable automatic slicing mechanism, including a base 6, a workbench 3, a feeding slide 1, a fruit and vegetable limiting groove 5, a rotating blade 7, a slice baffle 9, a rotating baffle 2, and a transmission assembly And four sliding baffles 4. The workbench 3 is arranged above the base 6, and the workbench 3 is provided with a through hole for the blanking slideway 1 to pass through, and the lower end surface of the workbench 3 is provided with a rectangular slide rail 13. The feeding chute 1 is obliquely set through the through hole on the workbench 3, and the fruit and vegetable limiting groove 5 is arranged at the lower end discharge port of the feeding chute 1. V-shaped groove, and the V-shaped groove is located directly below the corresponding slide rail in the rectangular slide rail 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com