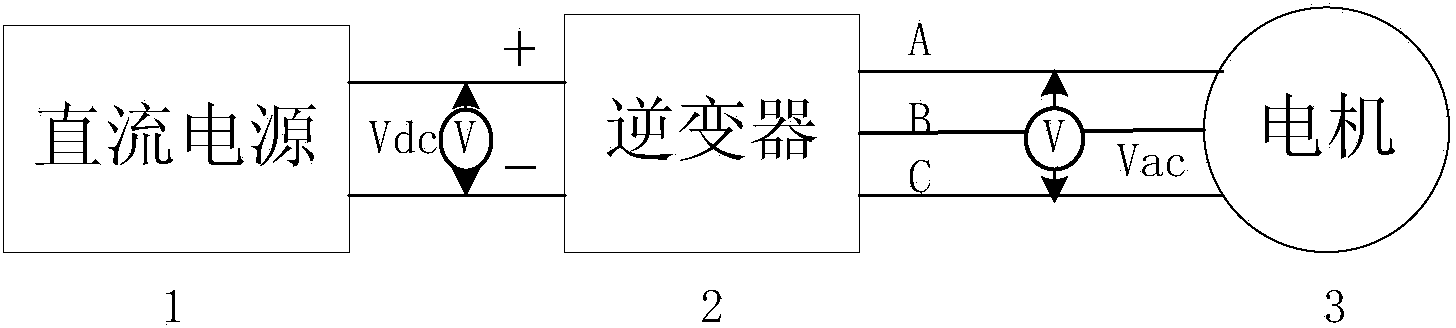

Motor terminal voltage measuring instrument of alternating current frequency conversion motor

A technology of terminal voltage and AC frequency conversion, which is applied in the direction of measurement using digital measurement technology, can solve the problems of large error, high digital sampling frequency, and inability to accurately consider inverter voltage drop, so as to avoid measurement voltage error and improve The effect of controlling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

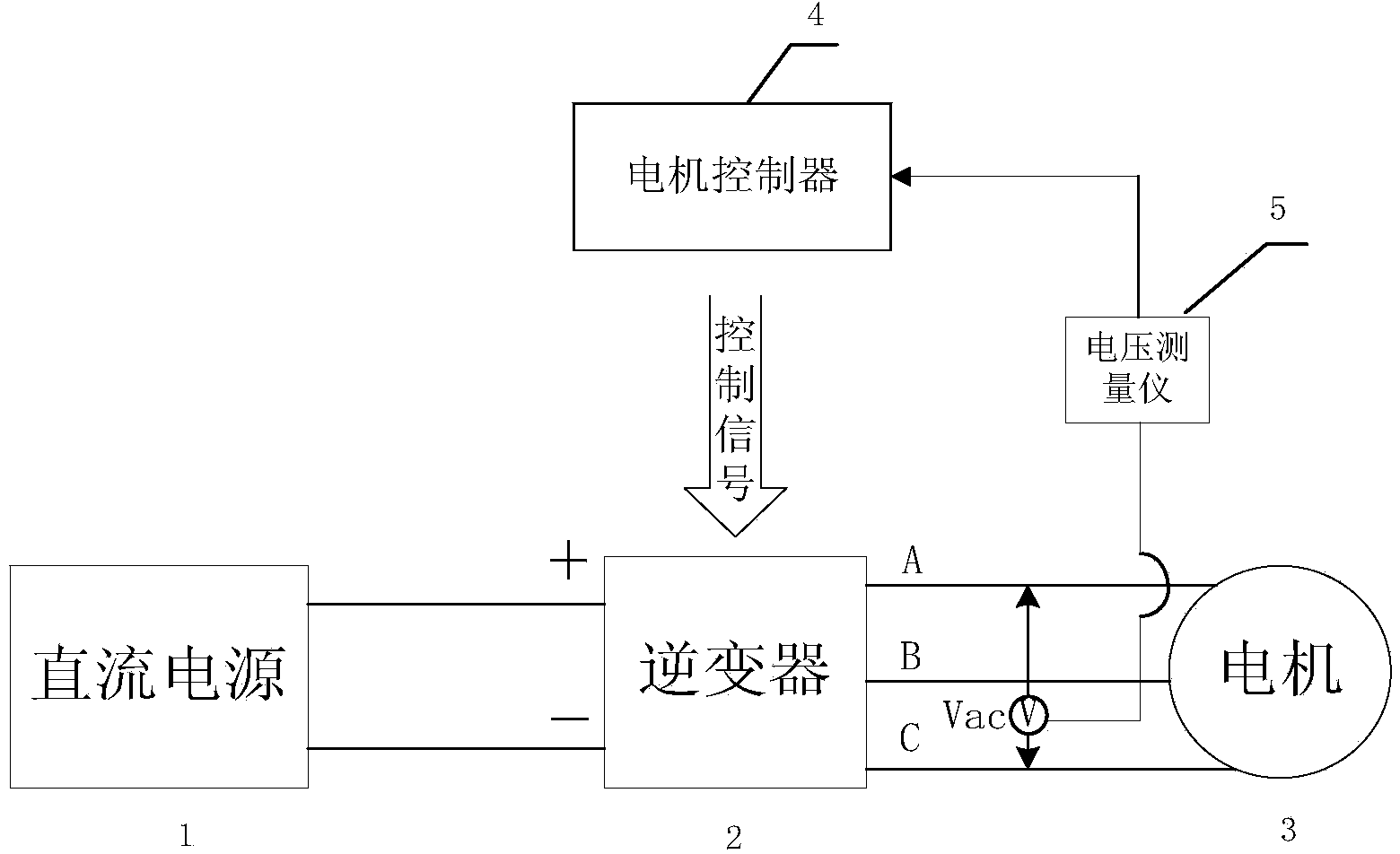

[0033] Embodiment 1, the output terminal Vc of the HV-C04 series sensor is connected to one end of the sampling resistor (chip resistor model 0201) with a wire, and the other end of the sampling resistor (chip resistor model 0201) is connected to the American AD company’s model. The Vi pin of the AD574A ADC chip, the R and D ports of the AD574A ADC chip are connected to the IN port of the FPGA, and the sampling resistor (the chip resistor of the model 0201), the ADC chip of the model AD574A, and the FPGA are welded on the same On one circuit board, the output port of the voltage measuring instrument is connected with the input end of the motor controller 4 with a signal line.

Embodiment approach 2

[0034] Embodiment 2, the output terminal OUT of the LV25-P series sensor uses a wire to connect one end of the sampling resistor (chip resistor model 0402), and the other end of the sampling resistor (chip resistor model 0402) is connected to the ADC model ADC0809 The IN0 and IN1 pins of the chip, the D0 port and the D1 port of the ADC chip of the model ADC0809 are connected to the IN port of the FPGA (Field Programmable Logic Gate Array), among which the sampling resistor (the chip resistor of the model 0402), the model of the ADC0809 The ADC chip and the FPGA are welded on the same circuit board, and the output port of the voltage measuring instrument is connected to the input end of the motor controller 4 with a signal line.

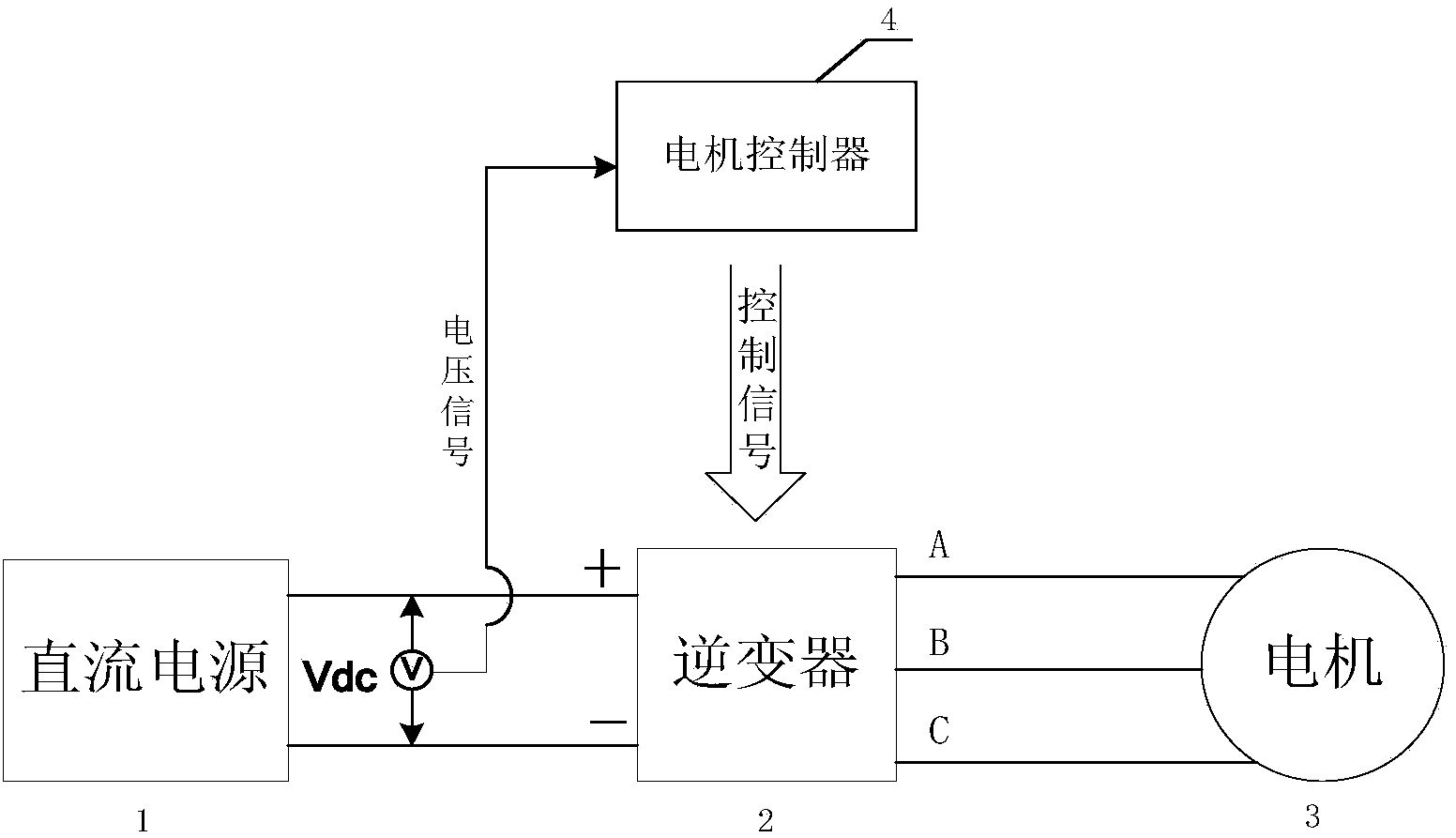

[0035] The working principle of the AC variable frequency motor control system using the terminal voltage measuring instrument of the AC variable frequency motor according to the present invention:

[0036] The DC power supply 1 outputs the DC voltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com