Plasterboard manufacturing system with distribution bridge parking device

A technology of gypsum board and tensioning device, which is applied in the field of gypsum board, can solve the problems of increased fatigue coefficient, elongated chain, inaccurate docking position, etc., and achieve industrialized production, improve the accuracy of board feeding, and simple operation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

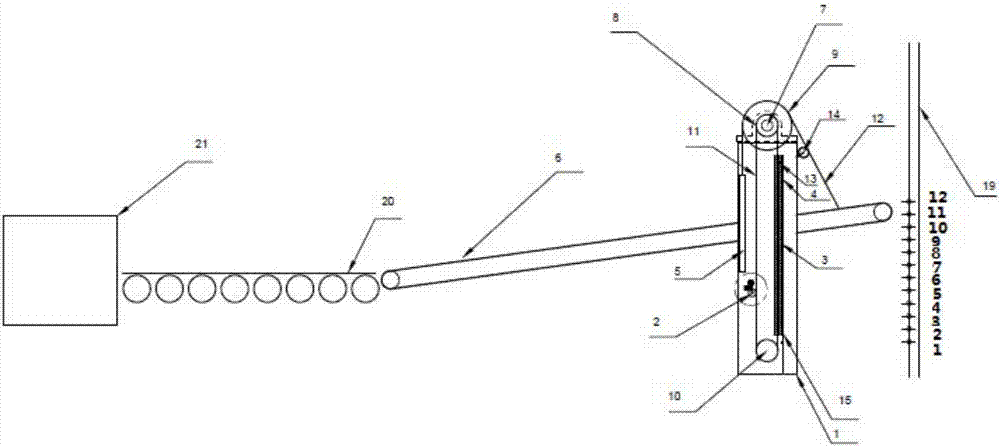

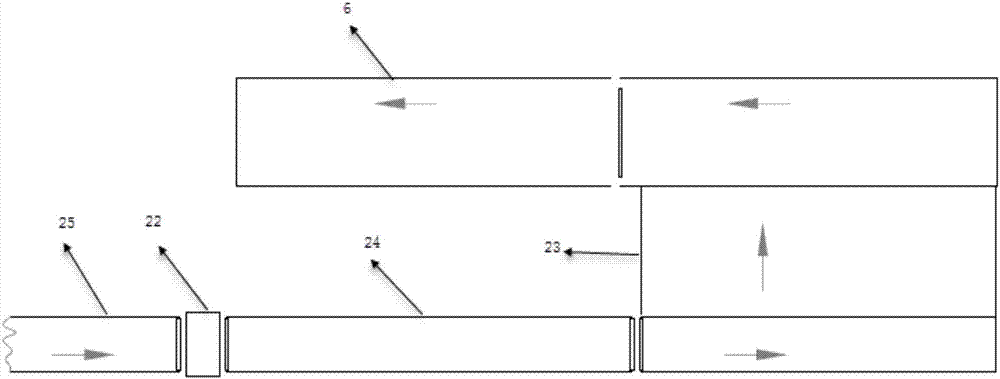

[0029] Such as figure 1 As shown, a system for preparing gypsum boards with a distributing bridge docking device includes a distributing bridge docking device, a board making device 21, a dryer 19, and a board delivery roller table 20; The distribution bridge 6 is set at the right end of the plate delivery roller table 20; the docking device transports the gypsum board delivered by the plate delivery roller table 20 to the dryer 19 on the right for drying.

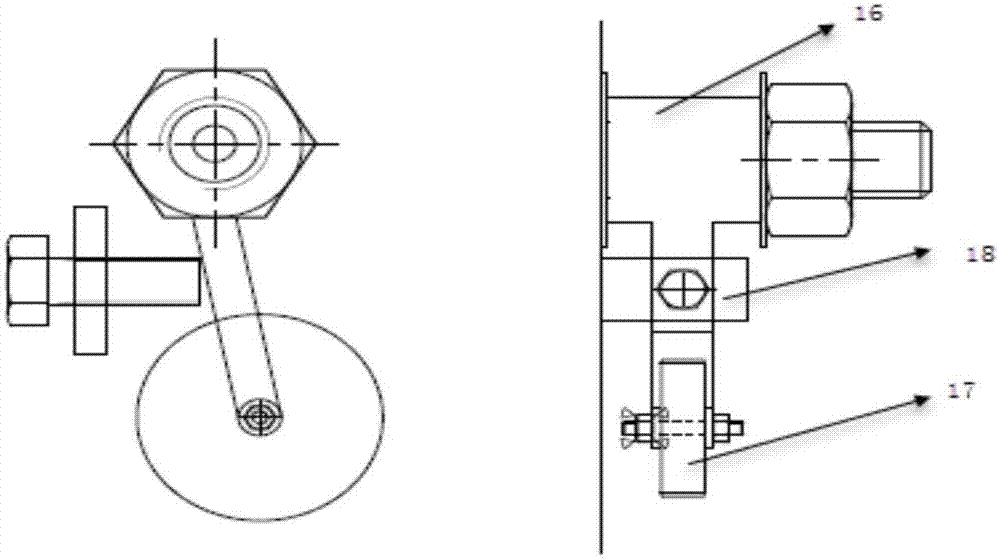

[0030] The distributing bridge docking device includes a housing 1, a tensioning device 2, a chain baffle 3, an inductor 4, a counterweight 5 and a distributing bridge 6; a transmission shaft 7 is arranged directly above the housing 1, and on the transmission shaft 7 A small sprocket 8 and a large sprocket 9 are provided; the small sprocket 8 and the inner bottom sprocket 10 of the housing 1 form a closed loop through the first chain 11; the tensioning device 2 is arranged on the outside of the first chain 11 on the left; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com