Intermediate supporting structure for rigidity improving and shock absorption

A technology of intermediate support and rigidity, which is used in control devices, non-rotational vibration suppression, transportation and packaging, etc., can solve the problems of difficult assembly of intermediate support components, difficult technical realization, and unfavorable vibration reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] An intermediate support structure for improving stiffness and shock absorption of the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

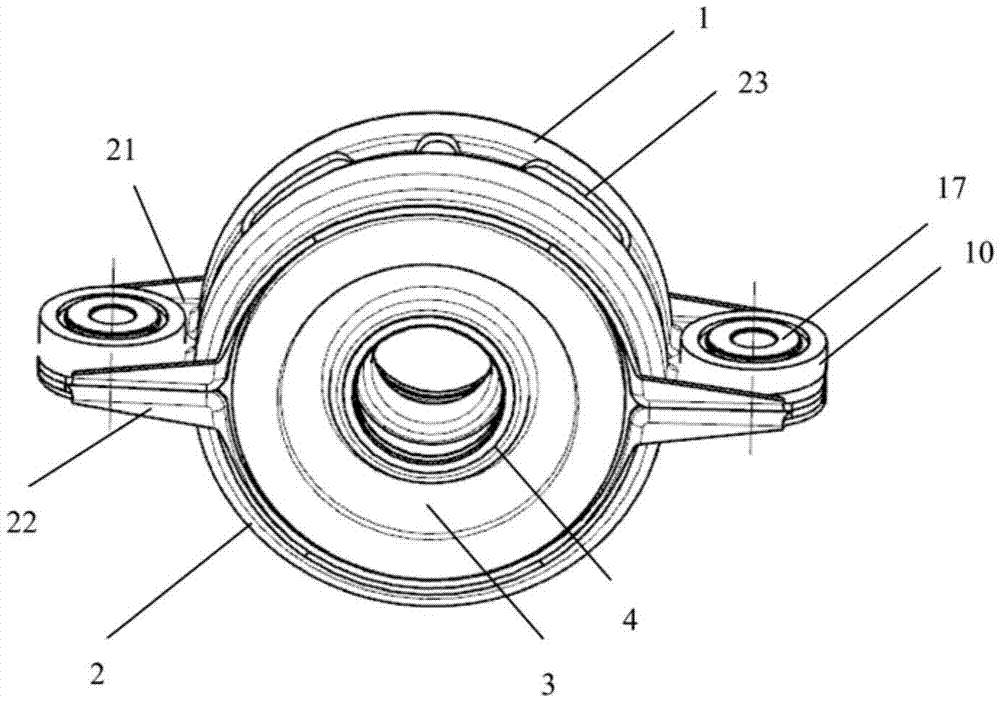

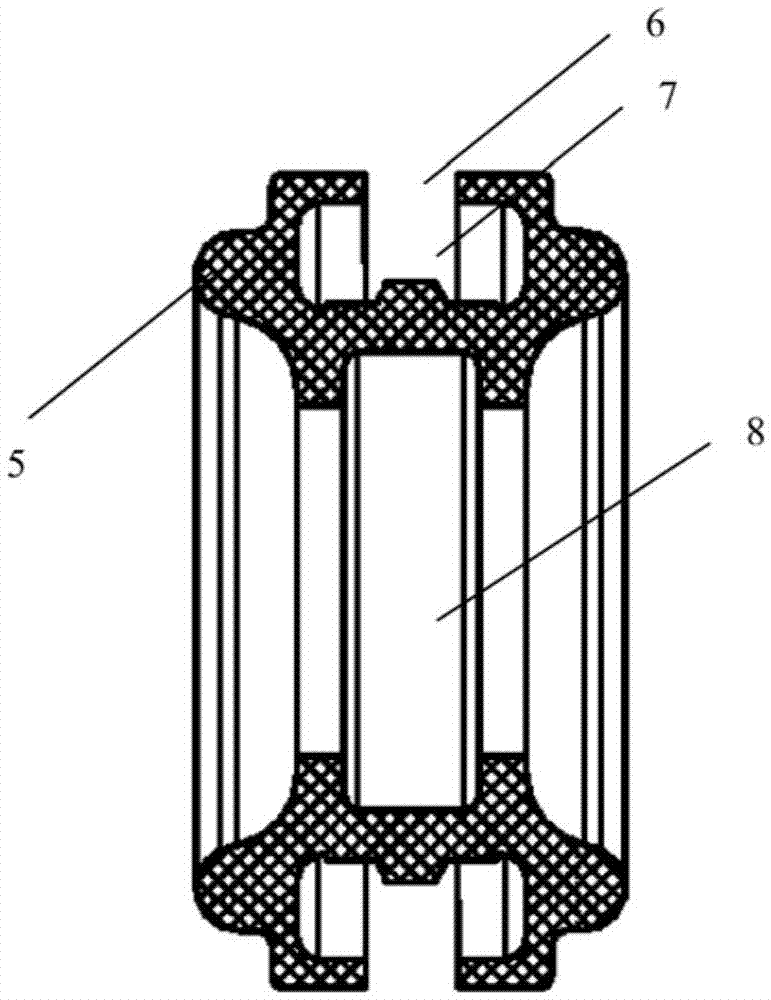

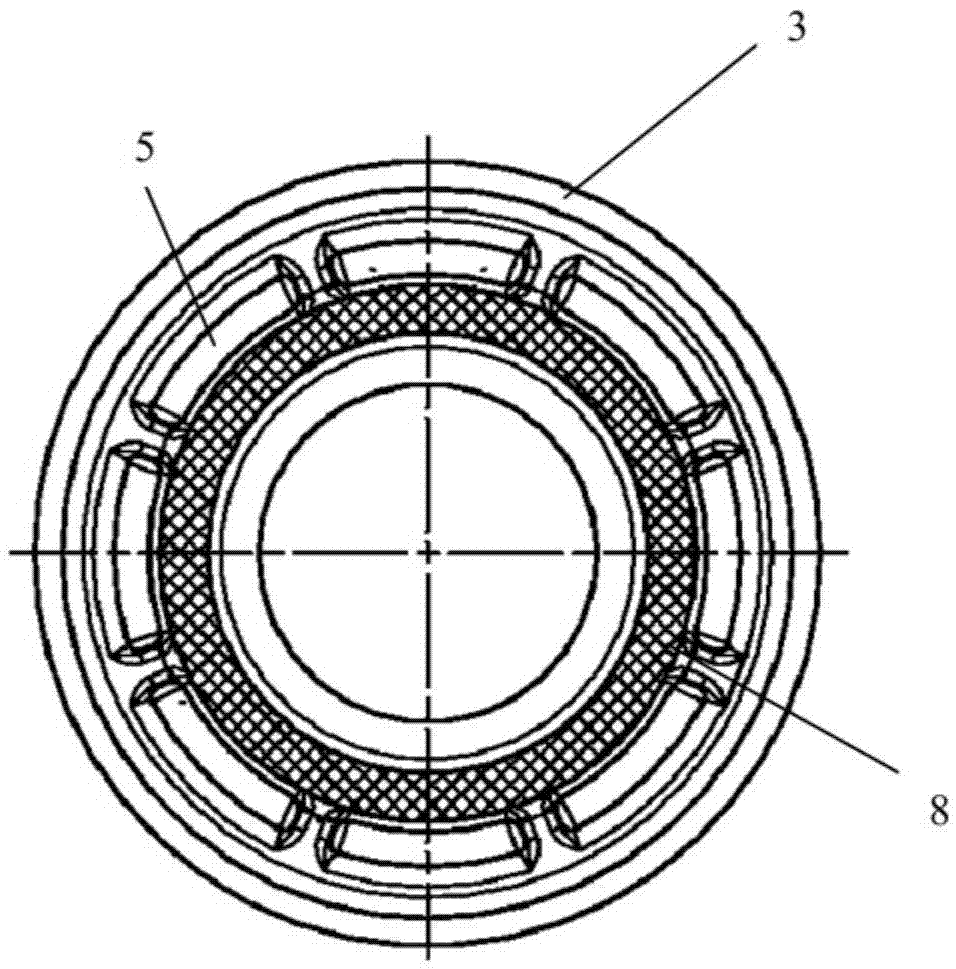

[0029] like Figure 1-7 As shown, an intermediate support structure for improving stiffness and shock absorption includes an upper bracket 1, a lower bracket 2, a rubber pendant 3 and a bearing 4, and the upper bracket 1 and the lower bracket 2 are semicircular and fastened together Set, the rubber pendant 3 is ring-shaped, the outer ring surface of the rubber pendant 3 is clamped in the circular space formed after the upper bracket 1 and the lower bracket 2 are fastened, and the rubber pendant 3 The inner ring surface is provided with a first groove 8, the bearing 4 is assembled in the first groove 8, and the rubber pendant 3 is evenly provided with raised ribs between the inner ring surface and the outer ring surface 5. Compared with the prior art, in the technica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com