Electric-hoist walking mechanism of bridge crane

A technology for bridge cranes and traveling mechanisms, applied in the direction of traveling mechanisms, cranes, load hanging components, etc., can solve problems such as broken axles, unstable operation, dirty tracks, etc., to facilitate disassembly and maintenance, ensure smooth operation, The effect of reducing the number of motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

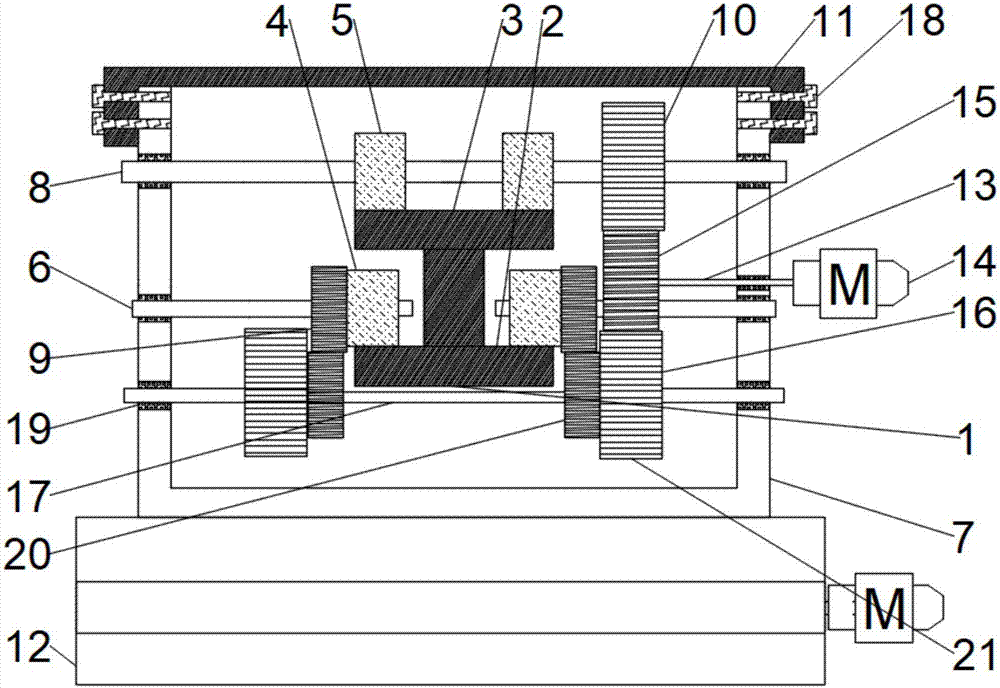

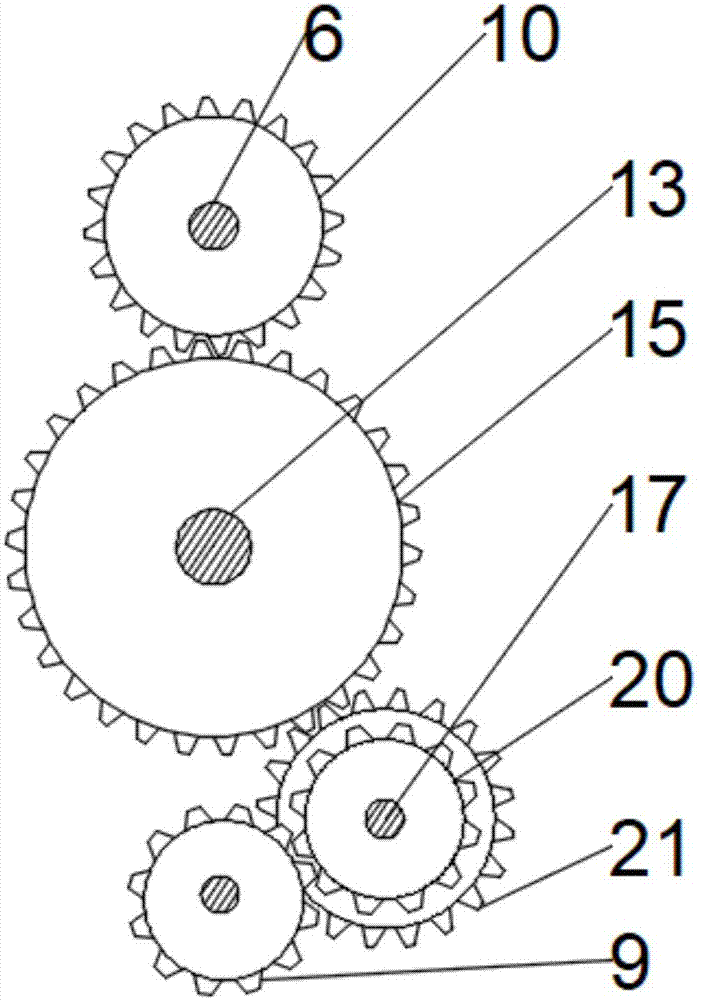

[0026] Such as figure 1 As shown, the present invention provides an electric hoist traveling mechanism of a bridge crane, which includes an I-beam 1. Generally, the running tracks of the electric hoist are arranged in the grooves on the left and right sides of the I-beam 1, that is, the I-beam 1 The upper surface of the lower horizontal steel is a track; the I-beam 1 includes a first track 2 and a second track 3, and the first track 2 is located directly below the second track 3, and the second track 3 is newly added. Track 2 is located on the original track, that is, the upper surface of the lower horizontal steel of I-beam 1, and the second track 3 is located on the top surface of I-beam. The design of double-layer tracks makes the bearing force of I-beam 1 more uniform, and the The word steel 1 is more difficult to deform.

[0027] Such as figure 1 As shown, the top surfaces of the first track 2 and the second track 3 are respectively connected with a first road wheel 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com