Crawler type lift vehicle

A crawler-type, lift truck technology, applied in the direction of lifting devices, vehicle components, control devices, etc., can solve the problems of difficult stepless speed change, poor controllability of mechanically driven work vehicles, etc., and achieve the effect of simple transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

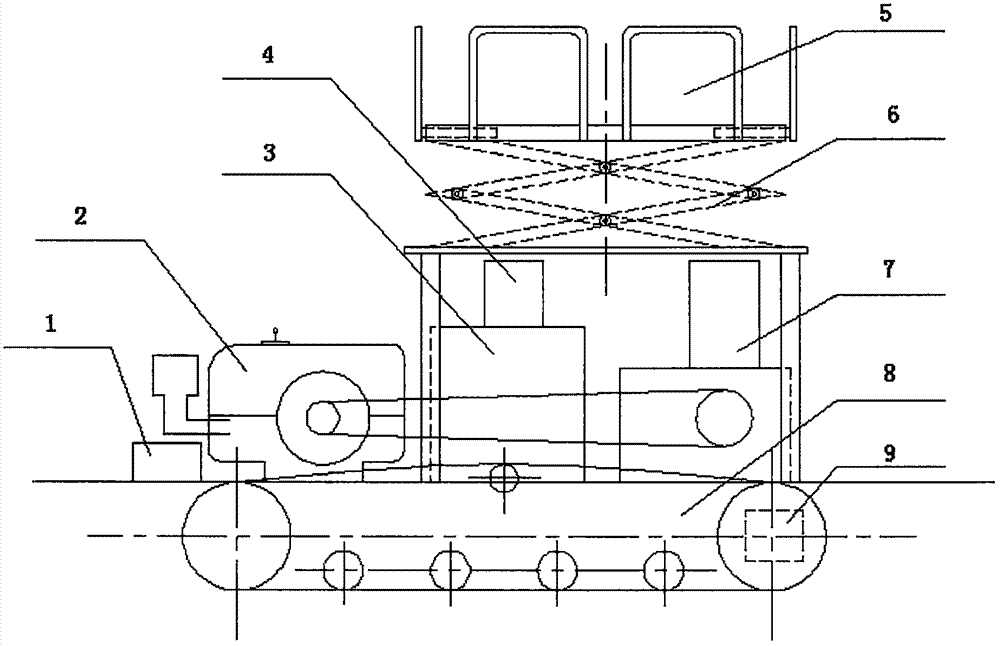

[0022] Below in conjunction with accompanying drawing, the crawler lift vehicle of the present invention will be described in further detail.

[0023] figure 1 The overall layout plan diagram of the crawler lift vehicle of the present invention is given, including a battery 1, an engine 2, a hydraulic oil tank 3, a hydraulic valve group 4, a working platform 5, a lifting mechanism 6, a hydraulic pump 7, a traveling mechanism 8, and a hydraulic motor 9 .

[0024] Described walking mechanism 8 is made up of rubber track, driving wheel, guide wheel, track roller, supporting pulley and hydraulic motor 9. After the engine 2 is started, the power is transmitted to the reducer through the V-belt, and the torque decelerated by the reducer is directly output to the hydraulic pump 7, and the hydraulic pump 7 converts mechanical energy into hydraulic energy and transmits it to the hydraulic motor through the hydraulic oil pipe and the hydraulic valve group 4 9, thus driving the hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com