Crusher driven by linear motor

A linear motor and crusher technology, applied in the field of construction engineering, can solve the problems of low crushing efficiency, complicated equipment maintenance, and heavy equipment.

Inactive Publication Date: 2017-10-24

JINGMEN CHUANGJIA MACHINERY TECH CO LTD

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The concrete floor crushers currently used in the field of construction engineering are not only heavy equipment, but the crushing efficiency is not high, and the equipment maintenance is complicated.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0009] Summary of the Invention The specific implementation of the lifting device has been described in detail and will not be repeated here. It should be explained that the crusher of the present invention is driven by a tubular linear motor. The working principle of this linear motor is a known technology and will not be repeated here. .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

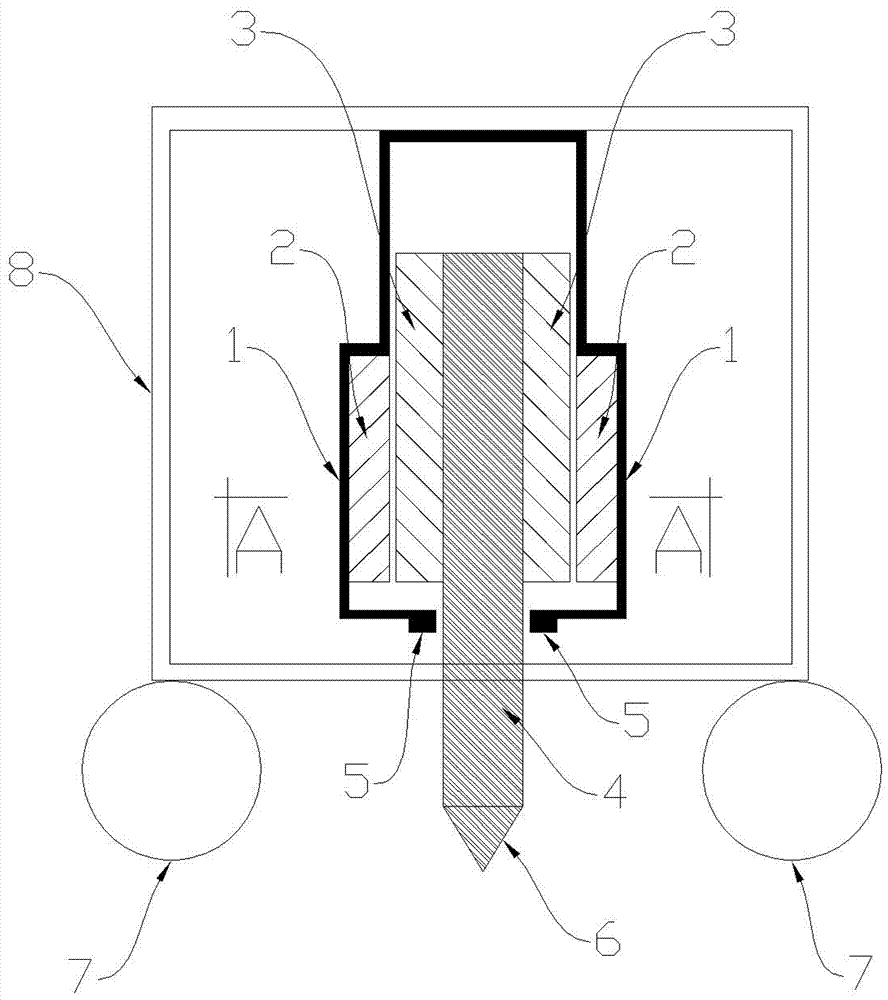

The invention provides a crusher driven by a linear motor. The crusher is mainly used for crushing concrete ground in the field of construction engineering, and is high in crushing efficiency and easy to maintain. The crusher mainly comprises a shell, a linear motor stator, a linear motor rotor, a center shaft, a bearing, a crushing head and a machine frame. According to the working principle, the linear motor rotor is connected with a forward power supply, and the linear motor rotor moves linearly and vertically upward along the linear motor stator and drives the central shaft and the crushing head to move linearly and vertically upward; when the linear motor rotor is connected with a reverse power supply, the linear motor rotor moves linearly and vertically downward along the linear motor stator and drives the central shaft and the crushing head to move linearly and vertically downward; the crushing head moves repeatedly to crush the concrete ground, and pushes the machine frame forward to crush the ground of the next place.

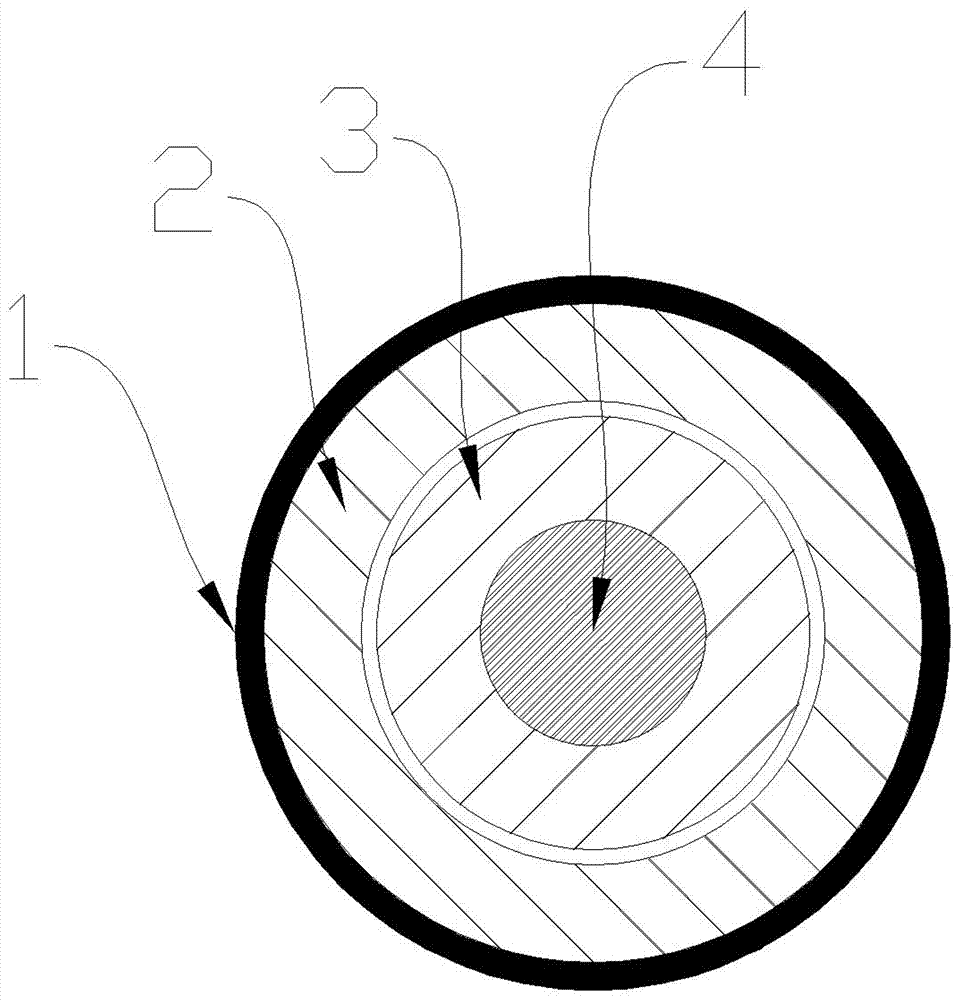

Description

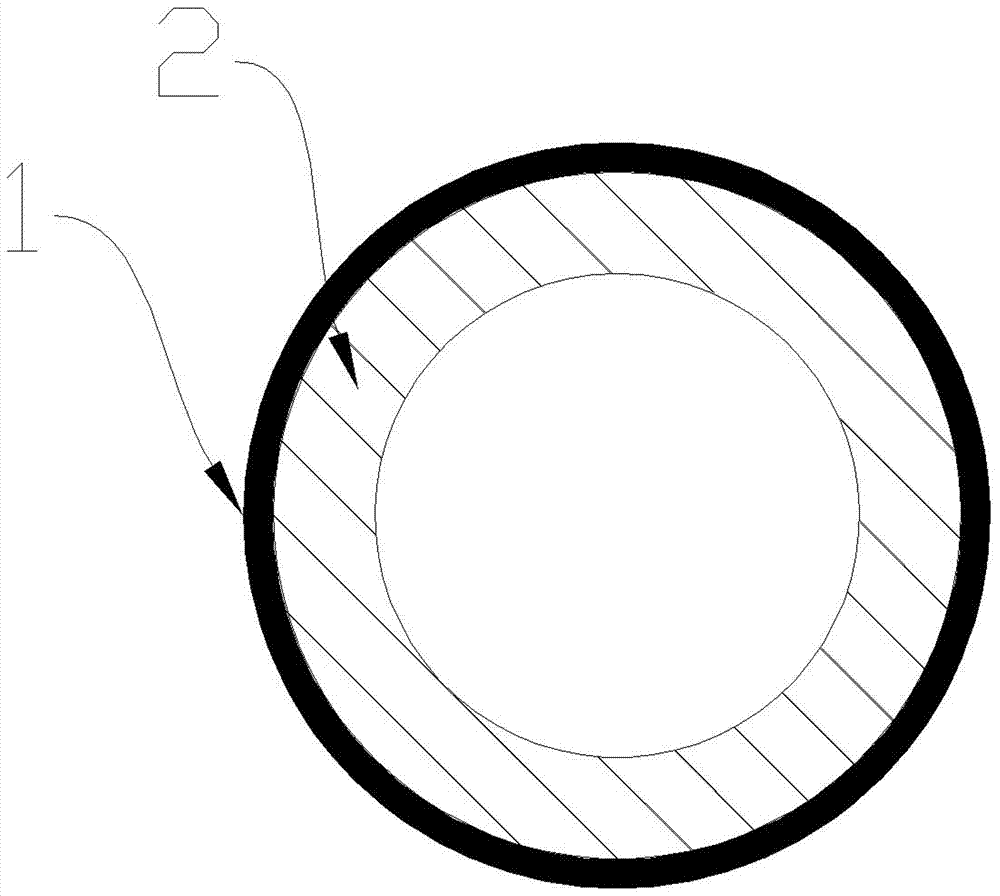

technical field [0001] The invention is mainly used for broken concrete ground in the field of construction engineering. Background technique [0002] The concrete floor crushers currently used in the field of construction engineering are not only heavy equipment, but also have low crushing efficiency and complicated equipment maintenance. Contents of the invention [0003] The present invention solves the above problems. It has high crushing efficiency and simple equipment maintenance; it mainly includes a casing (1), a linear motor stator (2), a linear motor mover (3), a central shaft (4), a bearing (5), The crushing head (6), the frame (8); the shell (1) is fixed to the frame (8), the frame (8) is fixed with wheels (7), the lower end of the shell (1) has a bearing (5), and the linear motor The stator (2) is fixed to the inner wall of the casing (1), the upper outer wall of the central shaft (4) is fixed to the inner wall of the linear motor mover (3), the lower part of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E01C23/12

CPCE01C23/124

Inventor 彭宝安

Owner JINGMEN CHUANGJIA MACHINERY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com