Anti-sloughing hole device and construction method of anti-sloughing hole

A construction method and anti-collapse hole technology, which is applied in the direction of earthwork drilling, bolt installation, mining equipment, etc., can solve problems such as construction difficulties, hole collapse, unusability, etc., and achieve long service life, good effect, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

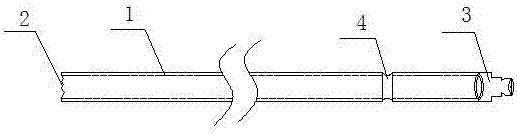

[0013] Such as figure 1 The anti-slump hole device shown includes a hollow tube 1, a drill tooth 2 and a connector 3, the front end of the hollow tube 1 is fixedly connected to the drill tooth 2, the rear end of the hollow tube 1 is equipped with a connector 3, and the hollow tube A through hole 4 penetrating through the hollow tube 1 is opened at a distance of 150-200 mm from the connecting head.

[0014] The length of the hollow tube 1 is 1100-1300mm, and the outer diameter of the hollow tube 1 is 45mm.

[0015] The diameter of the through hole 4 passing through the hollow tube 1 is 22mm.

[0016] A method for constructing an anti-slump hole utilizing an anti-slump hole device, comprising the following steps: 1. installing a drilling rig bracket and a cable anchor drill; The drilling rig constructs a 1100mm drilling hole; 3. Take out the anchor cable drilling rig and the solid drill pipe, install the anti-slump hole device on the anchor cable drilling rig, and perform seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com