Method for predicting dynamic open-flow capacity of fractured horizontal wells for tight sandstone gas reservoirs

A tight sandstone gas reservoir and open flow technology, applied in the field of gas field development and research, can solve the problems of not considering the time of open test, low practicability and reliability, and not considering the influence of the average permeability of the matrix in the fracturing area of the gas well, etc. Achieve the effect of good promotion and use value, strong practicability and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

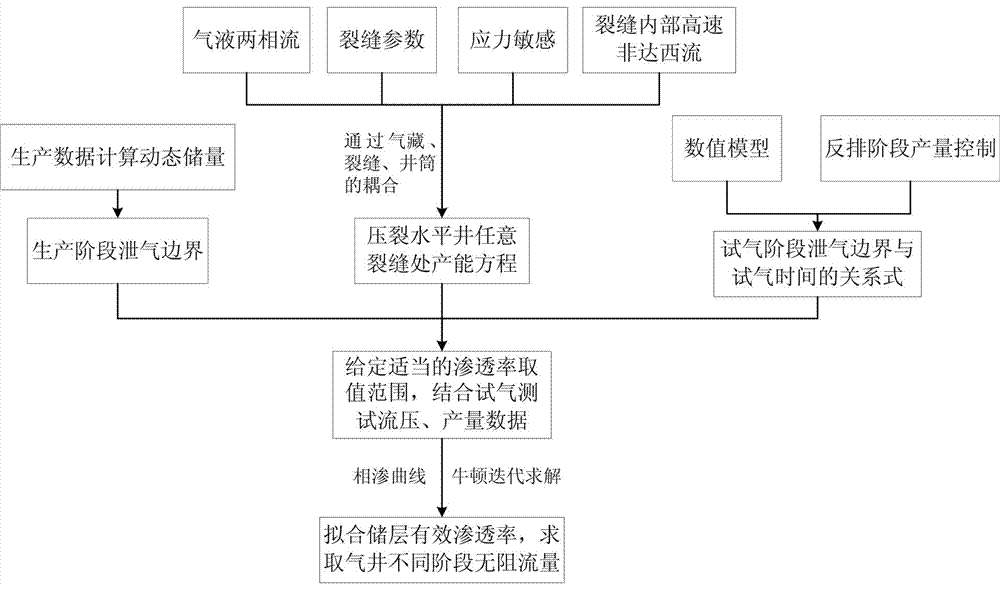

[0027] Such as figure 1 As shown, a dynamic open flow prediction method for fracturing horizontal wells in tight sandstone gas reservoirs includes the following steps:

[0028] 1) Based on the gas-liquid two-phase seepage theory, considering the influence of reservoir stress sensitivity and high-speed non-Darcy flow inside the fracture, using the principle of potential function superposition and the generalized pseudo-pressure of gas-water two-phase, the pressure is obtained through the coupling of gas reservoir, fracture and wellbore. The productivity equation of gas-liquid two-phase flow in any fracture of a fractured horizontal well:

[0029]

[0030] in: ψ e —The gas-water two-phase quasi-pressure corresponding to the boundary pressure, the unit is ×1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com