Full-automatic tube cutter

A tube sawing machine, fully automatic technology, applied in the direction of sawing machine, metal sawing equipment, metal processing, etc., can solve the problems of high defective rate, low processing efficiency, slow processing speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

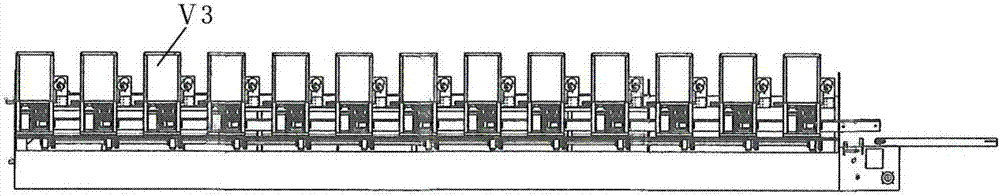

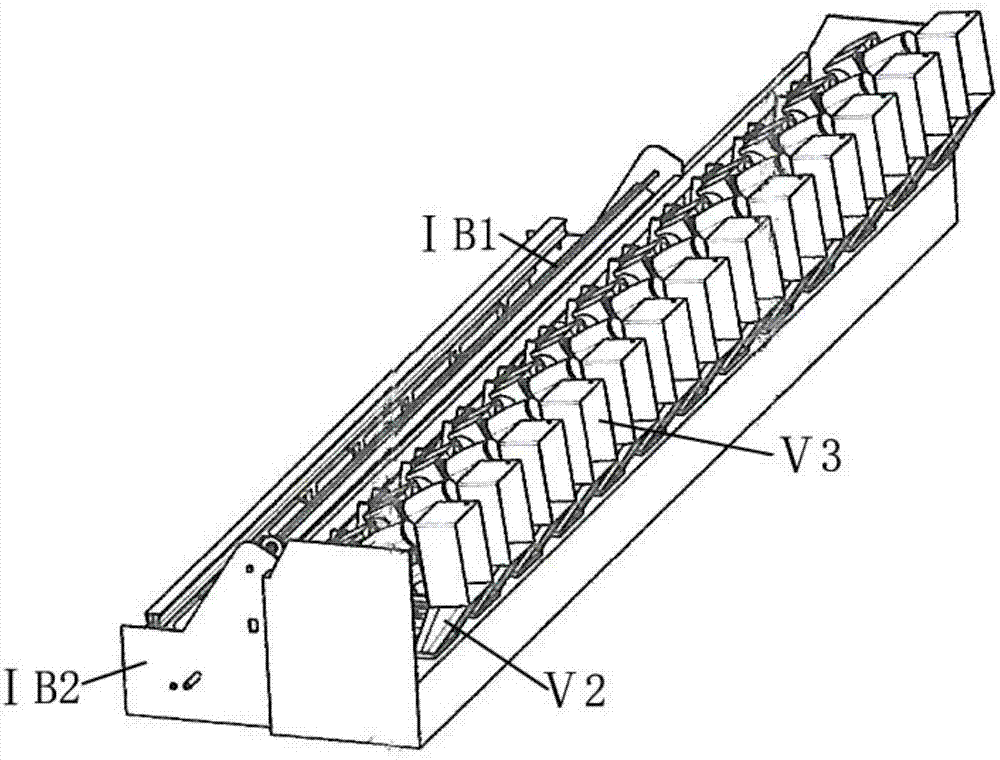

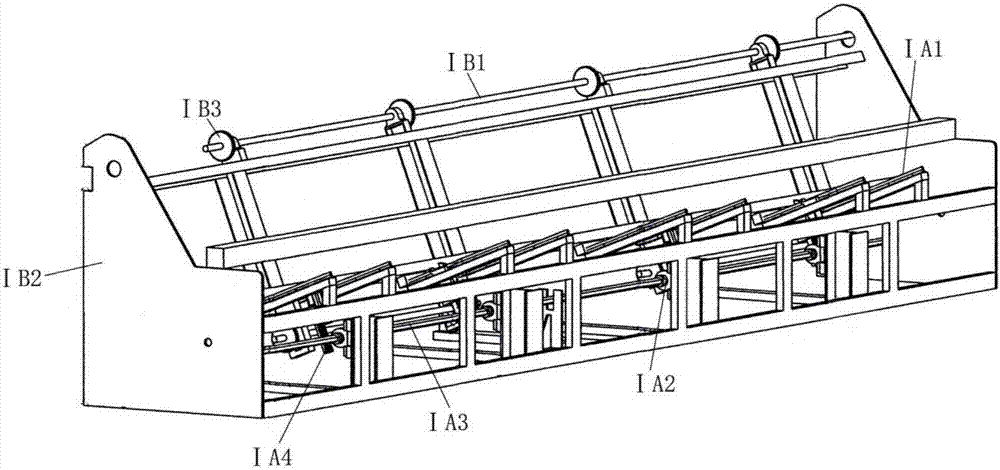

[0048] Such as figure 1 , figure 2 As shown, the fully automatic pipe sawing machine is composed of a pipe fitting jacking and feeding device, a horizontal base plate Ⅴ1, a main seat, a main control box Ⅴ3, a pipe fitting clamping device, an obliquely moving sawing device, and a lateral distance adjustment device. , characterized in that,

[0049] The main seat is welded to the middle of the top surface of the transverse base plate V1. The main seat includes the main seat III6 and the auxiliary seat II1. The auxiliary seat II1 is set on the left side of the main seat III6. Both the auxiliary seat II1 and the main seat III6 are made of thick steel plates A square frame structure formed by welding, four inclined steel plates V2 are welded on the top and front side of the transverse base plate V1, the top of the four inclined steel plates V2 is welded with the main control box V3, and the bottom surface of the transverse base plate V1 is welded with two Guide sleeve Ⅴ4, the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com