Large-diameter rotor assembling tool assembly and using method thereof

A technology of rotor assembly and large diameter, applied in aircraft parts, metal processing, manufacturing tools, etc., can solve the problem of inability to press the rotor in place, and achieve the effect of simple structure, anti-tilt, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

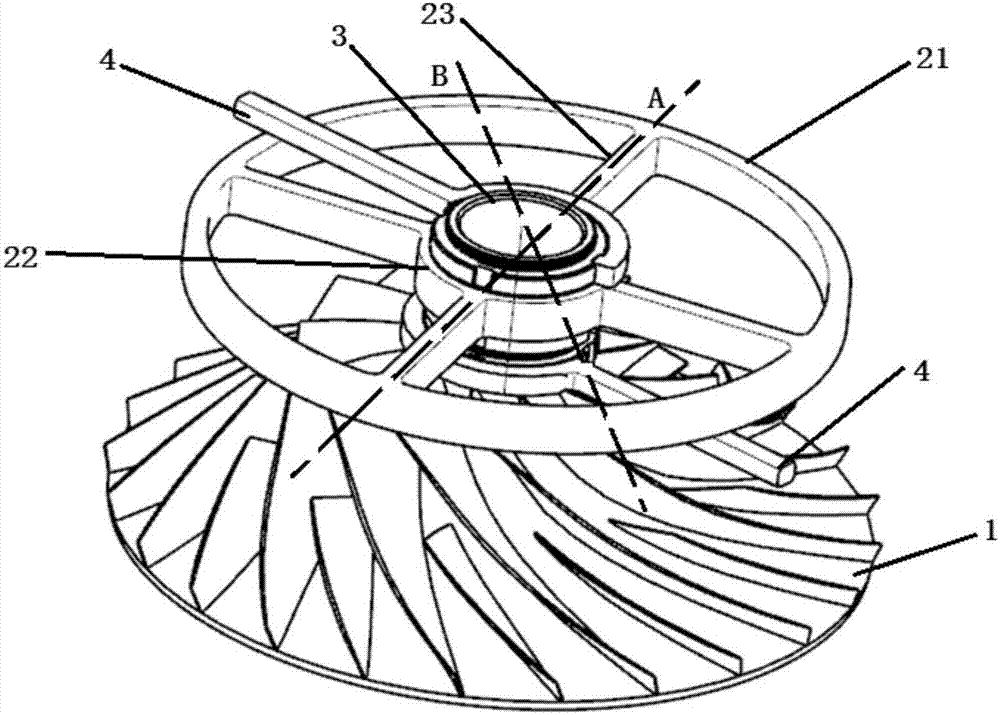

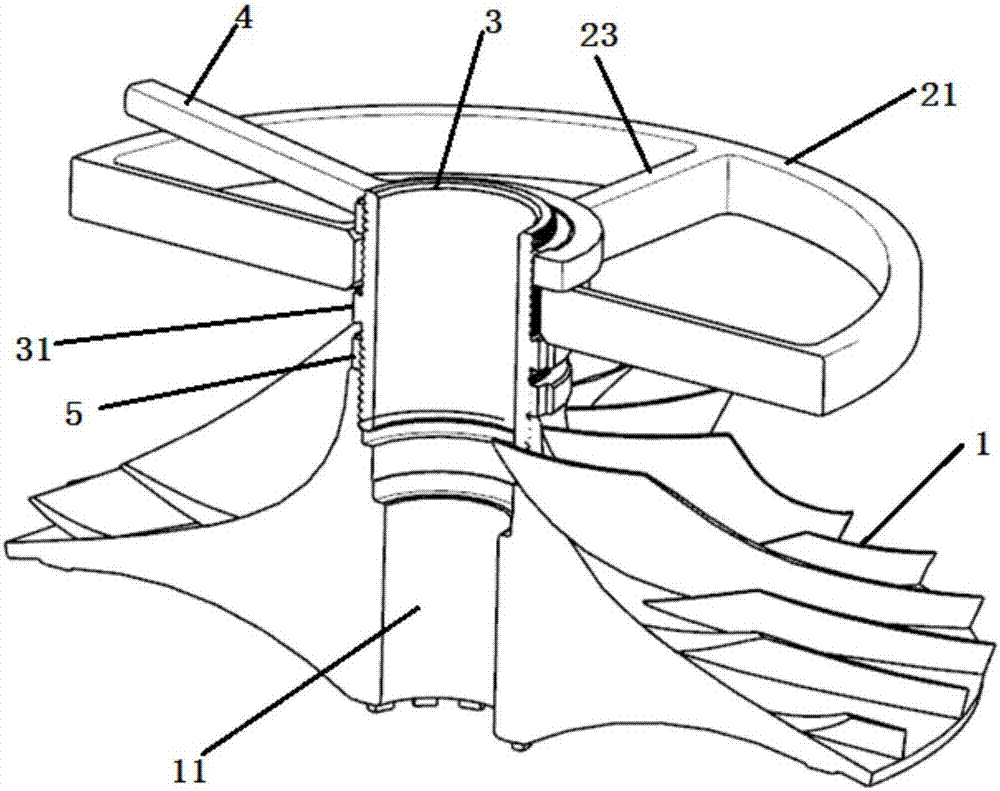

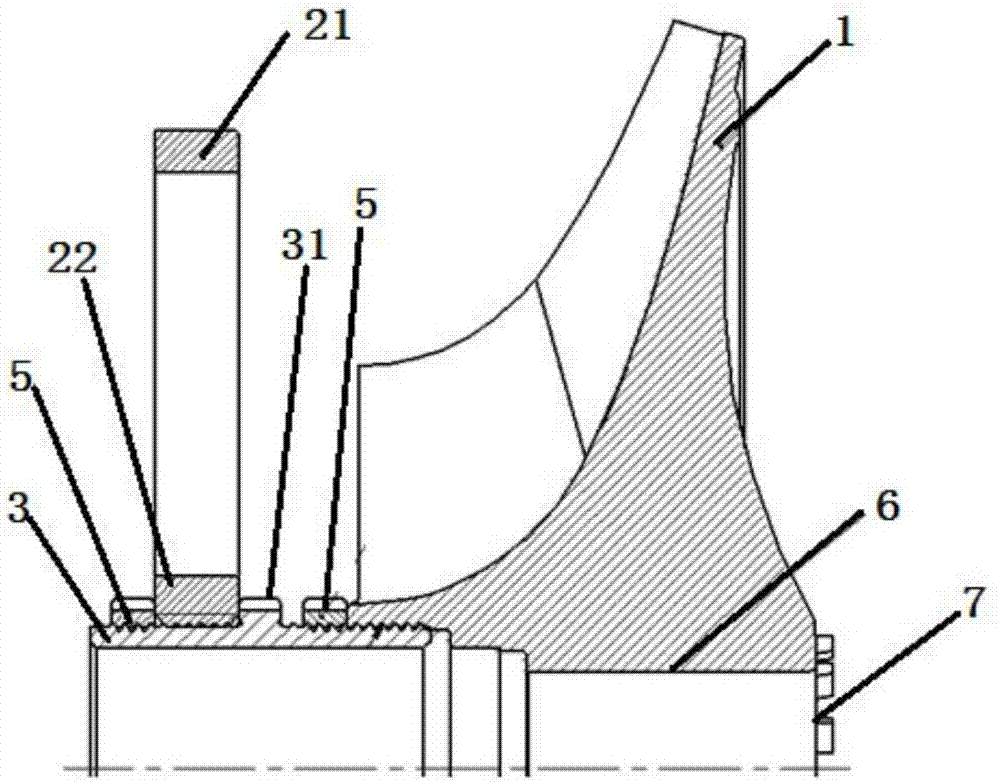

[0023] Example 1 as Figure 1 to Figure 3 As shown, the large-diameter rotor assembly tooling assembly of this embodiment includes a hollow sleeve 3 provided with external threads and a turntable arranged in the shape of a steering wheel. The turntable includes an inner ring 22 and an outer ring 21 arranged coaxially, and the outer ring 21 and the inner ring 22 are fixedly connected by four rigid spokes, the diameter of the outer ring 21 is half of the maximum diameter of the rotor 1, and the four rigid spokes 23 are evenly distributed on the circumference between the inner ring 22 and the outer ring 21, the The bottom of the hollow sleeve 3 is threadedly connected to the top of the assembly hole 11 of the rotor 1, and the lock nut 5 is used to limit the position; the inner ring 22 is threaded to the hollow sleeve 3, and the middle part of the hollow sleeve 3 is provided with a limiting part 31, the inner The ring 22 is fixed on the upper part of the hollow sleeve 3 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com