Concrete mixing equipment for hydraulic engineering construction

A technology for water conservancy projects and mixing equipment, applied in cement mixing equipment, clay preparation equipment, chemical instruments and methods, etc., can solve problems such as dust splashing, waste of manpower, uneconomical, etc., to reduce noise, speed up removal, and reduce investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

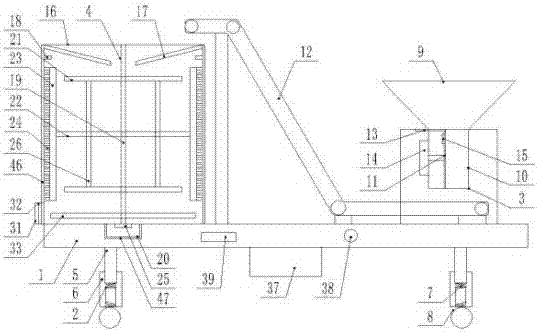

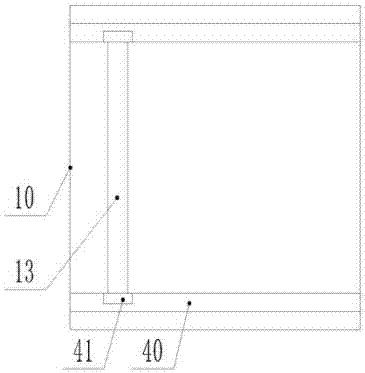

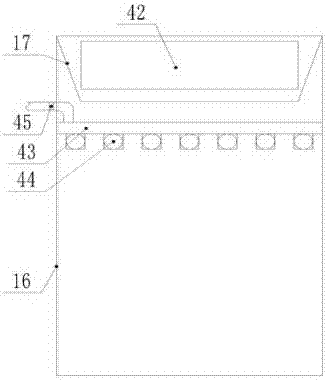

[0022] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6As shown, a concrete mixing equipment for water conservancy construction includes a basic rectangular bottom plate 1, the lower end of the basic rectangular bottom plate 1 is provided with a cushioning device 2, and the upper end is provided with a material delivery device 3 and a stirring device 4, and the cushioning device 2 is composed of the support feet 5 arranged at the four corners of the lower end surface of the basic rectangular bottom plate 1, the shock absorber 6 provided at the lower end of the support leg 5, the shock absorber spring 7 and the shock absorber 6 provided in the shock absorber 6 The moving wheel 8 that is provided with at the lower end is composed of, and the upper surface of the front end of the basic rectangular base plate 1 is provided with a material transport device 3, and the material transport device 3 is composed of a rectangula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com