Milk powder cover in-mold labeling delayed ejection mold structure

A milk powder and labeling technology, which is applied to home appliances, other home appliances, household components, etc., can solve problems that affect product quality, error-prone, product appearance scratches, etc., to reduce defective rate and labor costs, improve quality, and optimize The effect of texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

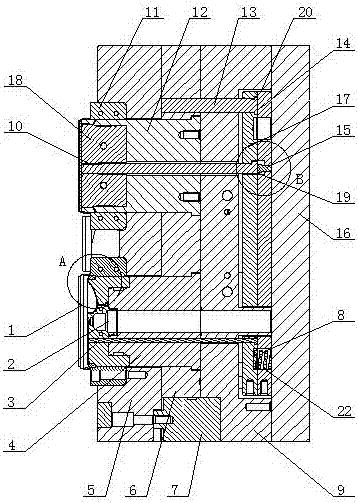

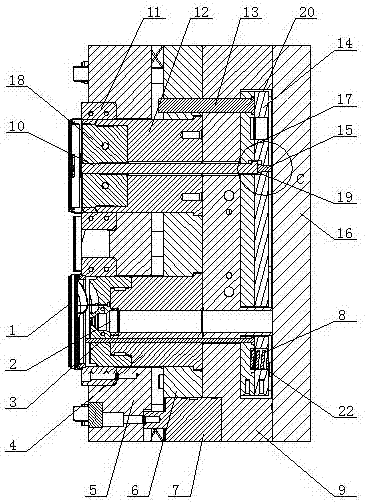

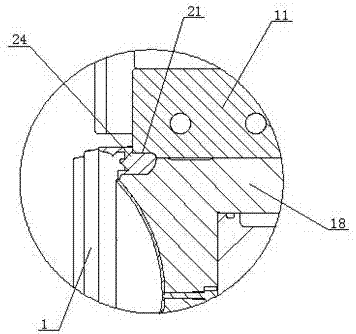

[0024] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0025] Such as figure 1 , figure 2 As shown, a delayed ejection mold structure for realizing in-mold labeling of milk powder caps includes a front mold and a rear mold. The front mold and the rear mold are provided with a product cavity, and the finished product 1 of the milk powder cap obtained by injection molding is located on one side of the front mold The cover surface of the milk powder cover finished product 1 can be directly labeled, and the front mold includes a back plate 16, a supporting plate 9, a solid core plate 6, a push plate 5, a reset plate 17, a synchronous ejection mechanism and a delayed ejector arranged in sequence. One side of the solid core plate 6 is provided with a first core 4 and a second core 12, the other sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com