A large equipment installation system

A technology for installing systems and large-scale equipment, which is applied in the field of transportation systems, can solve problems such as increasing the construction period of offshore platforms, delaying the construction time of offshore platform equipment compartments, and affecting the construction of offshore platforms in sections, so as to shorten the construction period and make the system applicable strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

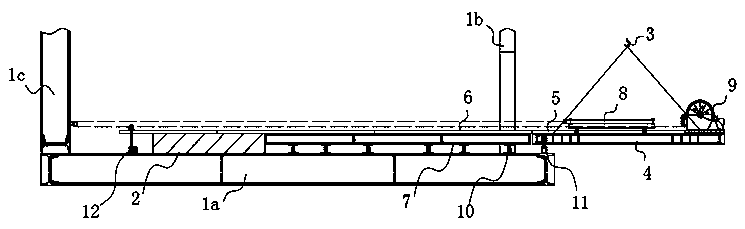

[0037] The offshore platform equipment installation system of the present invention is used to transport power equipment to the equipment fixing base 2 on the upper surface of the equipment cabin deck 1a. One side of the equipment cabin deck 1 is the rear side wall 1c of the equipment cabin, and the other side is the equipment cabin. The cabin front side wall 1b has an equipment cabin entrance on the front side wall.

[0038] Such as figure 1 As shown, the installation system mainly includes a suspension base 4, a first linear guide rail 5, a second linear guide rail 6, a second linear guide rail bracket 7, a movable platform 8, a movable platform driving mechanism 9, a rail bracket height adjustment mechanism 10, a base The seat end supports a buffer mechanism 11 and an anti-warping mechanism 12 .

[0039] The suspension base 4 is suspended by the hoisting system 3 on the edge side of the deck 1a of the equipment compartment of the offshore platform, and is located at the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com