A kind of preparation technology of glass bottle with three-dimensional pattern of virtual reality and near reality

A preparation process and three-dimensional effect technology, which is applied in glass manufacturing equipment, manufacturing tools, glass blowing, etc., can solve the problems of poor image expression and inability to form a three-dimensional effect, etc. Rich variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

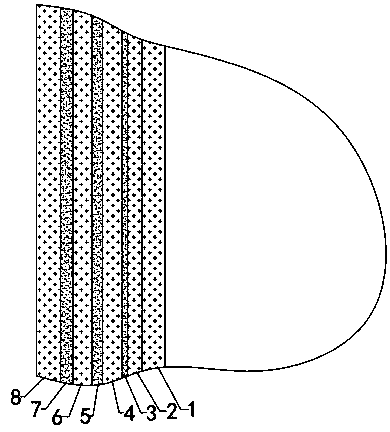

Image

Examples

Example Embodiment

[0026] Example 1

[0027] Composition by weight: 40 parts of soda ash, 97 parts of quartz powder, 2 parts of fluorite powder, 1 part of alumina, 3 parts of sodium nitrate, 1 part of clarifying agent, 10 parts of calcium carbonate, prepared crystal material, and melted into crystal material molten glass liquid;

[0028] Composition by weight: 40 parts of soda ash, 90 parts of quartz powder, 0.5 part of clarifying agent, 1 part of zinc oxide, 15 parts of alumina, 3 parts of sodium nitrate, 5 parts of barium carbonate, 4 parts of sodium fluorosilicate, 4 parts of sodium chloride Parts, 2 parts of borax, prepared white jade material, and melted into molten glass of white jade material;

[0029] 1) Take the 1425℃ crystal material molten glass and blow it into glass bubbles. After the glass bubbles are cooled to 860℃, dip the 1425℃ white jade molten glass to cover the white jade to form a double glass bubble;

[0030] 2) The double-layer glass bubble is immersed in the melted pigment paste...

Example Embodiment

[0035] Example 2

[0036] Composition by weight: 41 parts of soda ash, 99 parts of quartz powder, 1.7 parts of fluorite powder, 0.9 parts of alumina, 2.8 parts of sodium nitrate, 0.9 parts of clarifying agent, 11 parts of calcium carbonate, prepared crystal material, and melted into crystal material molten glass liquid;

[0037] Components by weight: 39 parts of soda ash, 89 parts of quartz powder, 0.6 parts of clarifying agent, 1.1 parts of zinc oxide, 17 parts of alumina, 2.7 parts of sodium nitrate, 6 parts of barium carbonate, 3.5 parts of sodium fluorosilicate, 4.2 parts of sodium chloride Parts, 2.3 parts of borax, prepared white jade material, and melted into molten glass of white jade material;

[0038] 1) Take the molten glass of crystal material at 1430°C and blow into glass bubbles, cool the glass bubble to 875°C, then dip the molten glass of white jade material at 1430°C to cover the white jade to form a double glass bubble;

[0039] 2) The double-layer glass bubble is im...

Example Embodiment

[0044] Example 3

[0045] Composition by weight: 39 parts of soda ash, 96 parts of quartz powder, 2.2 parts of fluorite powder, 1.1 parts of alumina, 3.2 parts of sodium nitrate, 1.1 parts of clarifying agent, 9 parts of calcium carbonate, prepared crystal material, and melted into crystal material molten glass liquid;

[0046] Composition by weight: 41 parts of soda ash, 91 parts of quartz powder, 0.45 parts of clarifying agent, 0.9 parts of zinc oxide, 15 parts of alumina, 3.2 parts of sodium nitrate, 5 parts of barium carbonate, 5.2 parts of sodium fluorosilicate, 3.5 parts of sodium chloride Parts, 1.7 parts of borax, prepared white jade material, and melted into molten glass of white jade material;

[0047] 1) Take the 1420℃ molten glass of crystal material and blow it into a glass bubble. After the glass bubble is cooled to 800℃~900℃, dip the molten glass of 1420℃ white jade material into the white jade to form a double glass bubble;

[0048] 2) The double-layer glass bubble is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com