Elastic grouting counter-pressure sealing structure of expansion joint and construction method of elastic grouting counter pressure sealing structure

A technology of sealing structure and expansion joints, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of repeated leakage of sealing materials, falling, etc., achieve effective sealing, excellent anti-seepage ability, and solve repeated leakage. and the effect of falling sealing material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

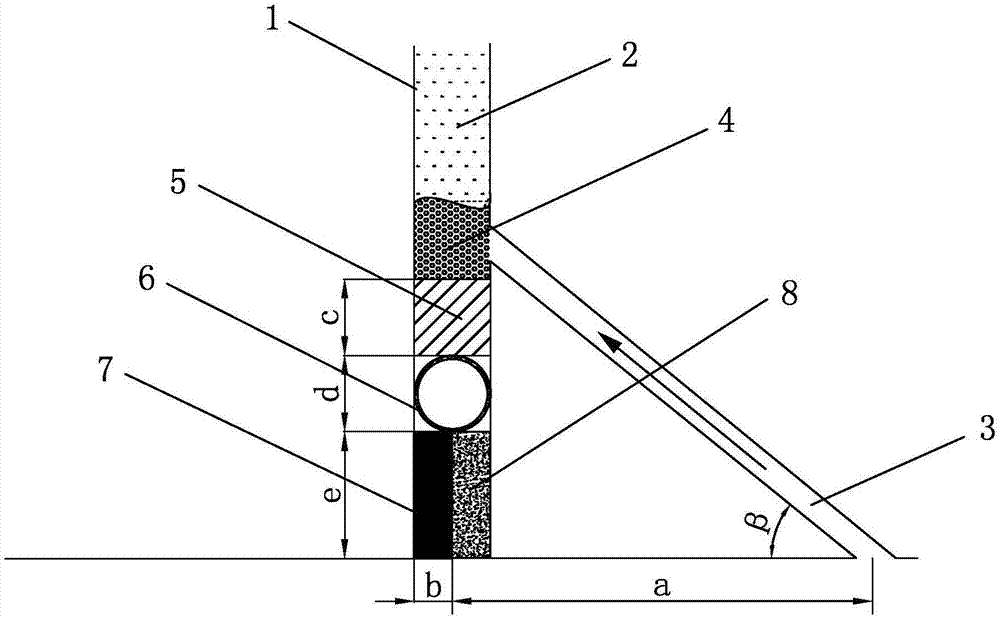

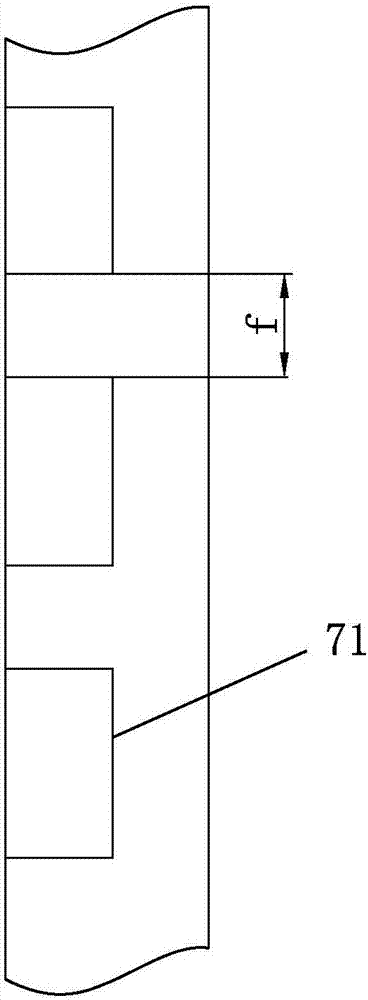

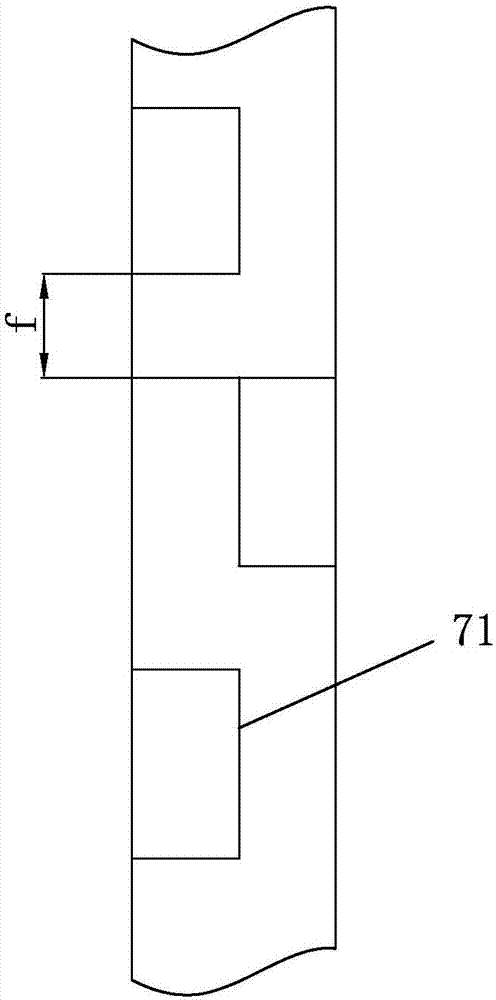

[0033] see figure 1 , the elastic grouting back pressure sealing structure of the expansion joint, including deformation joints located between two concrete interfaces in urban underground pipe galleries, high-speed rail tunnels, ordinary railway tunnels, highway tunnels and other structures and containing groundwater 2 or containing groundwater 2 in rainy seasons 1. A grouting material layer 4 , an elastic material layer 5 , an elastic tube 6 , and an epoxy mortar pedestal 7 are sequentially arranged inside the deformation joint 1 for blocking groundwater 2 .

[0034] Further, the concrete surface is provided with a grouting hole 3 connected to the inside of the deformation joint 1, and an aluminum tube is embedded in the grouting hole 3. After the grouting material layer 4 is grouted through the aluminum tube, the entrance of the aluminum tube is seal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com