Water meter measurement stabilizing method

A stabilization method, water meter technology, applied in the direction of volume measurement, measurement device, measurement capacity, etc., to achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

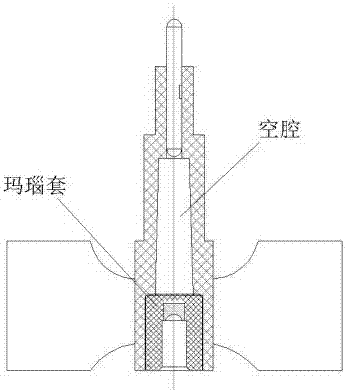

[0014] The method for stabilizing water meter measurement comprises the following process steps:

[0015] 1) Inject the paraffin wax with light specific gravity and low melting point into the injection-molded impeller cavity;

[0016] 2) Fill the cavity of the impeller;

[0017] 3) Press into the agate sleeve, so that the impeller has no cavity with uncertain specific gravity, and the specific gravity and buoyancy of the impeller in the water are fixed, so that the temperature change of the water cannot affect the flow speed ratio of the water meter, thus ensuring the stability of the measurement accuracy of the water meter .

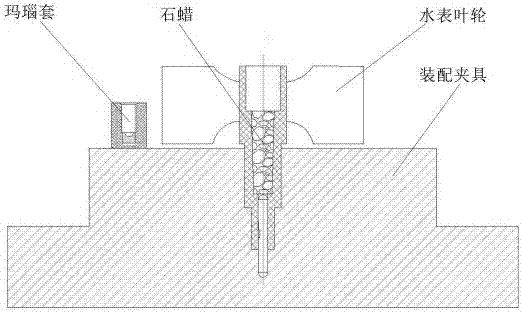

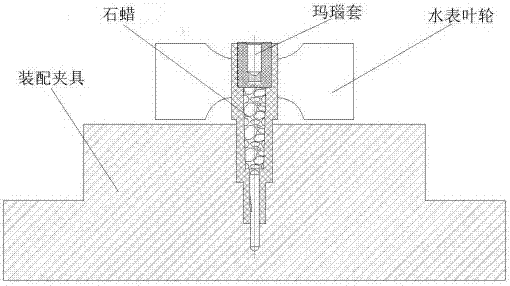

[0018] Further describe technical solution of the present invention in conjunction with accompanying drawing:

[0019] The method for stabilizing water meter measurement comprises the following process steps:

[0020] 1) if figure 2 Place the injection molded impeller part upside down on the work fixture table, as shown in ;

[0021] 2) According ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com