Simple platform for climbing operation

A platform and simple technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of increasing work risks, affecting work progress, and unstable operators, etc., without affecting the working time, improving the structural strength, and being easy to transport and carry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

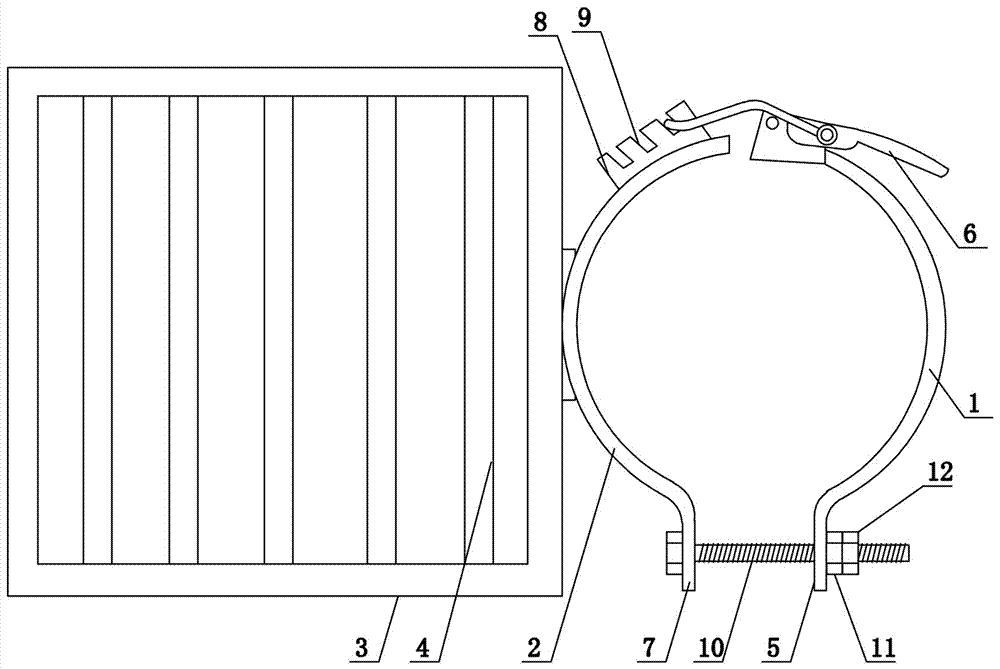

Embodiment 1

[0032] Such as figure 1 As shown, the present invention includes a first arc-shaped clamp 1, a second arc-shaped clamp 2 and a support mechanism. The support mechanism includes a rectangular frame 3 and a plurality of cross braces 4 welded on the rectangular frame 3. The first arc-shaped clamp One end of the hoop 1 is integrally formed with the first flange plate 5, the other end of the first arc-shaped hoop 1 is fixedly connected to the spring buckle 6, one end of the second arc-shaped hoop 2 is integrally formed with the second flange plate 7, and the second The other end of the arc-shaped clamp 2 is welded to a connecting plate 8, four card slots 9 are provided on the connecting plate 8, and a length adjustment mechanism is arranged between the first flange plate 5 and the second flange plate 7, and the length adjustment mechanism includes a screw rod 10 1. The positioning nut 11 and the back tightening nut 12 are clamped between the spring hasp 6 and the draw groove 9, and...

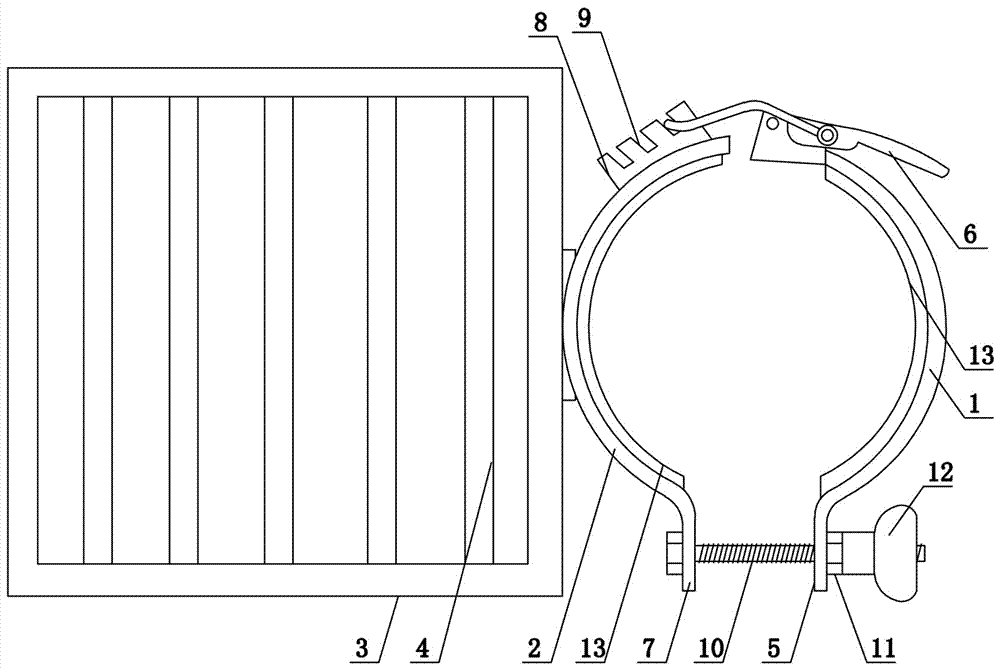

Embodiment 2

[0034] Such as figure 2As shown, the present invention includes a first arc-shaped clamp 1, a second arc-shaped clamp 2 and a support mechanism, and the inner walls of the first arc-shaped clamp 1 and the second arc-shaped clamp 2 are fixedly connected with anti-skid rubber pads 13, The support mechanism includes a rectangular frame 3 and a plurality of cross braces 4 welded on the rectangular frame 3. One end of the first arc-shaped clamp 1 is integrally formed with a first flange plate 5, and the other end of the first arc-shaped clamp 1 is fixedly connected to the Spring buckle 6, one end of the second arc clamp 2 integrally forms the second flange plate 7, the other end of the second arc clamp 2 is welded to the connecting plate 8, four card slots 9 are provided on the connecting plate 8, the second A length adjustment mechanism is arranged between a flange plate 5 and the second flange plate 7, and the length adjustment mechanism includes a screw rod 10, a positioning nu...

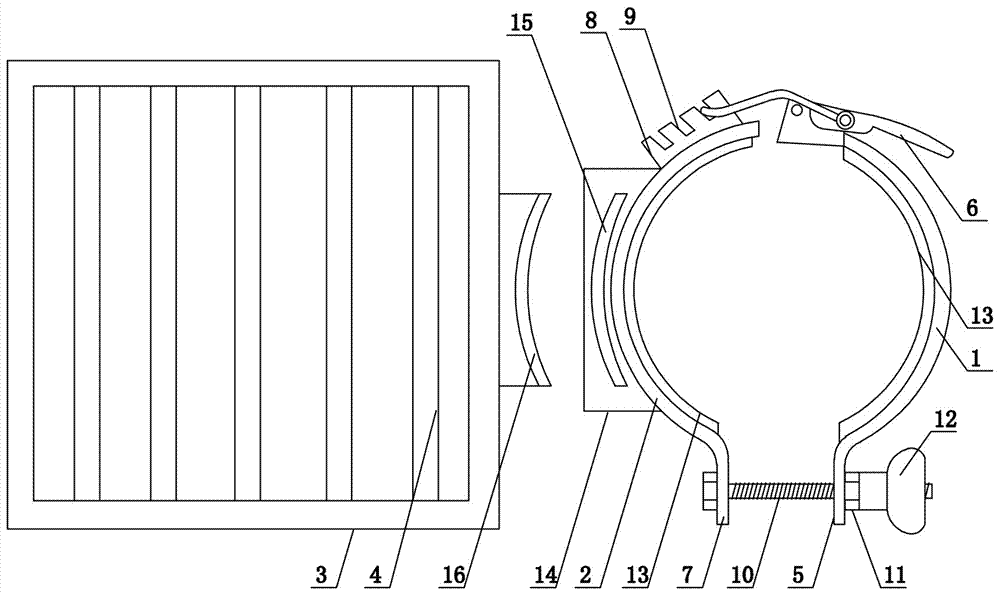

Embodiment 3

[0037] Such as image 3 As shown, the present invention includes a first arc-shaped clamp 1, a second arc-shaped clamp 2 and a support mechanism. The support mechanism includes a rectangular frame 3 and a plurality of cross braces 4 welded on the rectangular frame 3. The first arc-shaped clamp One end of the hoop 1 is integrally formed with the first flange plate 5, the other end of the first arc-shaped hoop 1 is fixedly connected to the spring buckle 6, one end of the second arc-shaped hoop 2 is integrally formed with the second flange plate 7, and the second The other end of the arc-shaped clamp 2 is welded to a connecting plate 8, four card slots 9 are provided on the connecting plate 8, and a length adjustment mechanism is arranged between the first flange plate 5 and the second flange plate 7, and the length adjustment mechanism includes a screw rod 10 , the positioning nut 11 and the back tightening nut 12, snap-fit between the spring hasp 6 and the slot 9, the outer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com