Digital motor power saver

A technology for electric motors and power savers, which is applied in the direction of motor generator control, electrical components, power factor control, etc., and can solve problems such as unbalanced three-phase terminal voltage, easy drift of capacitance value, and influence on operating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

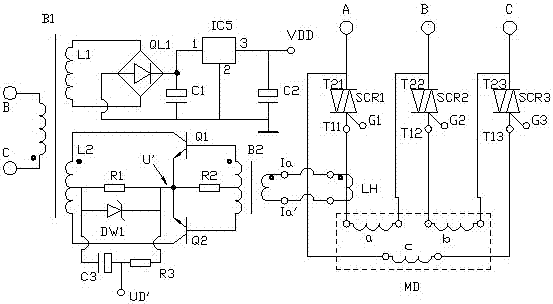

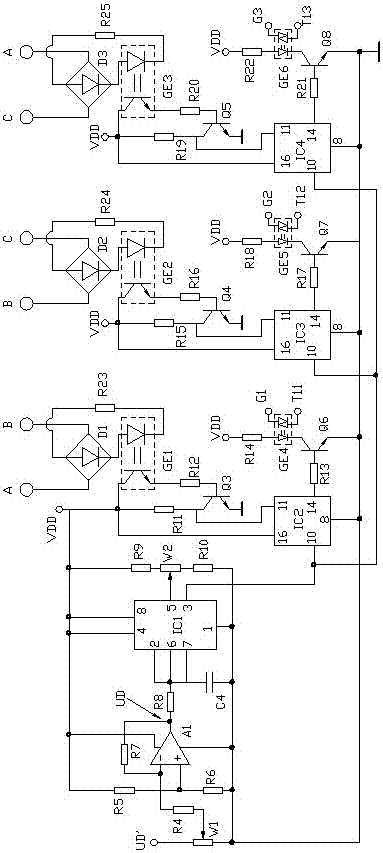

[0008] The specific embodiment of the present invention will now be described in conjunction with the accompanying drawings.

[0009] A digital motor saver, which includes three bidirectional thyristors connected in series between the windings of a three-phase motor MD and the mains, wherein the first bidirectional thyristor is controlled by the first trigger control circuit, the second The bidirectional thyristor is controlled by the second trigger control circuit, and the third bidirectional thyristor is controlled by the third trigger control circuit. It is characterized in that each trigger control circuit has the same circuit structure, which includes a counter and a synchronous pulse acquisition circuit. , flip-flop; the counting pulse input to the counter in each trigger control circuit comes to a voltage-controlled oscillator, and when the control voltage of the voltage-controlled oscillator control terminal changes, the counting pulse frequency of its output changes ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com