A catalyst for immobilized MPV reaction, its preparation method and its application in the production of nerol and geraniol

A catalyst and reaction technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, catalytic reaction, etc., can solve the problems of poor reaction selectivity, inability to quickly and effectively separate and reuse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

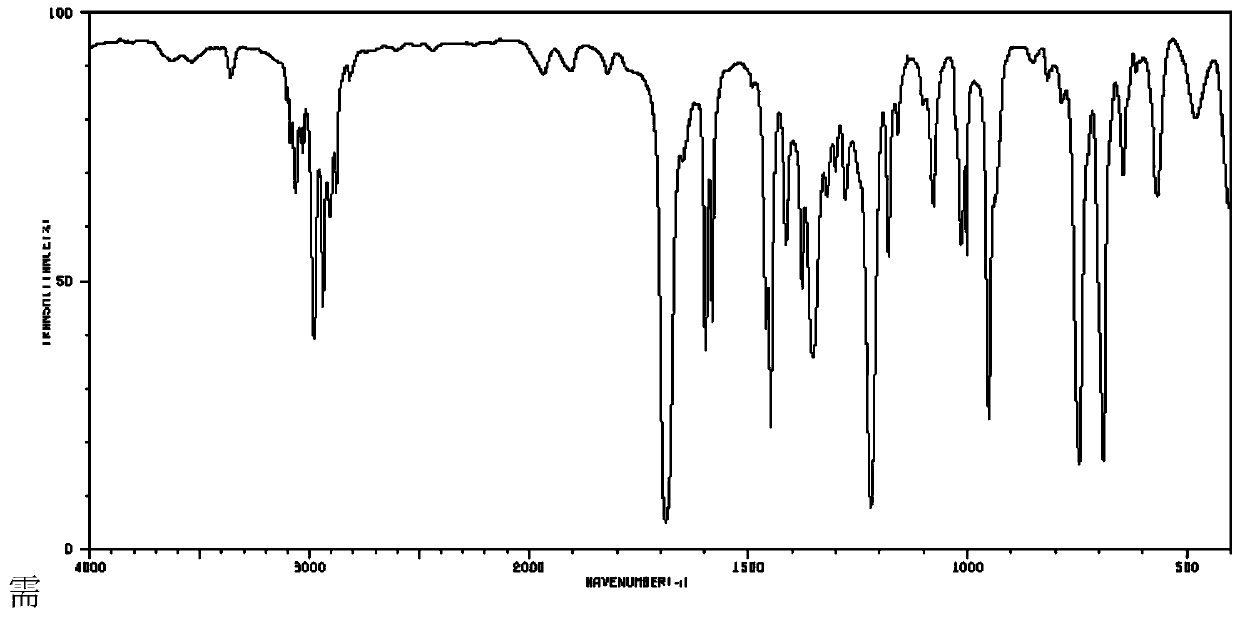

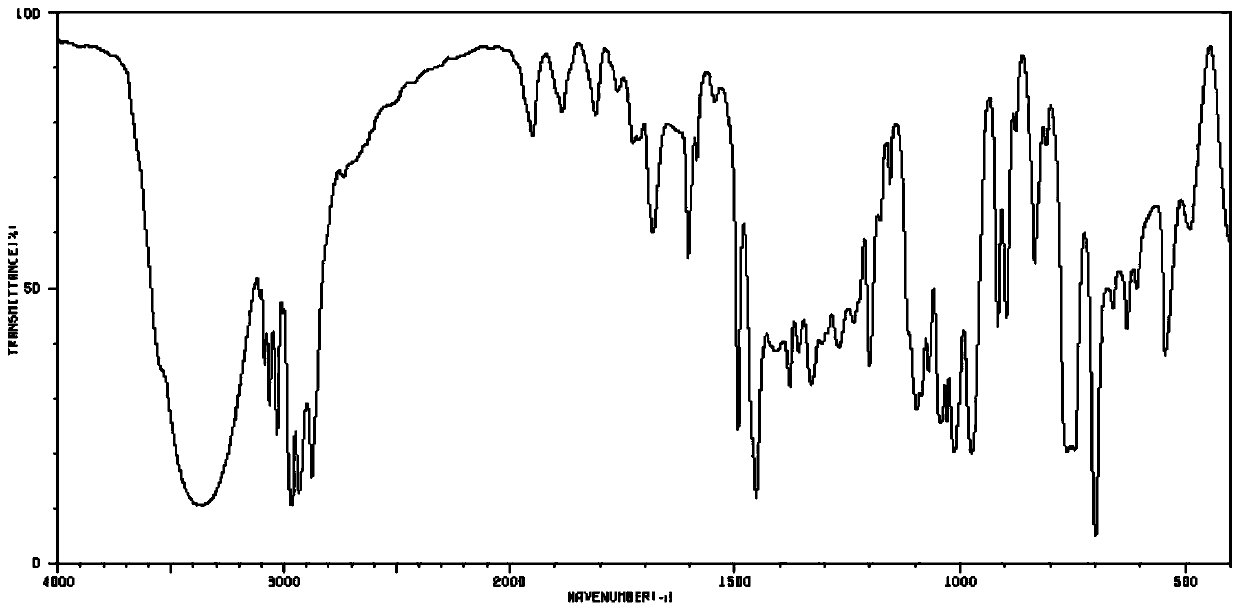

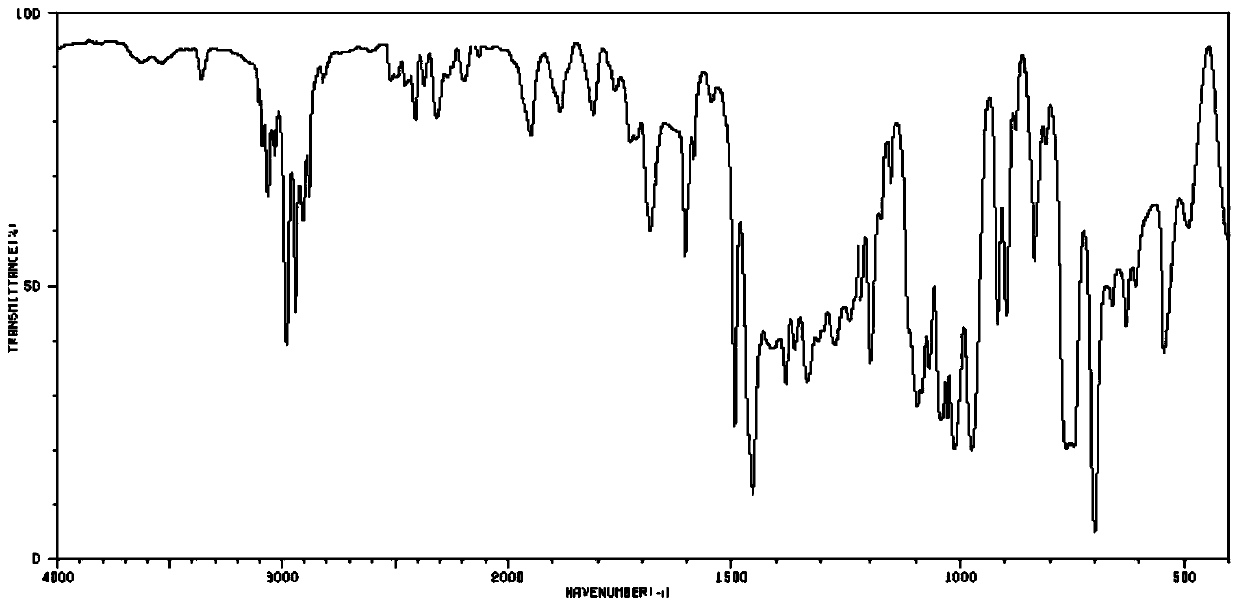

Image

Examples

Embodiment 1

[0042] 1. Free radical suspension polymerization: Weigh 160g of freshly steamed styrene and 70g of methyl vinyl ketone into a beaker, add 1.7g of azobisisobutyronitrile AIBN and stir to completely dissolve it for later use. In a four-neck flask equipped with a stirrer thermometer, dropping funnel and reflux condenser, add 200 mL of 0.1% polyvinyl alcohol-400 solution and 1 L of deionized water, and stir evenly. When the water bath is heated to 70°C, add 100g of the mixed monomer solution dissolved in AIBN, adjust the stirring speed to make the monomers evenly disperse into liquid droplets of appropriate size, slowly raise the temperature of the water bath to 90°C, and start dripping while keeping warm Add remaining mixed monomer solution. After the dropwise addition, the temperature was raised to 95° C., and the temperature was kept constant for 1 hour, and the reaction was completed. The reactant was filtered and fully washed, and air-dried at 50° C. to obtain the copolymer ...

Embodiment 2

[0052] Catalyst application

[0053] The catalyst of Example 1 is recovered, and the recovered catalyst is applied mechanically. Track the citral until the conversion rate > 99%, and the catalyst application results are shown in Table 1.

[0054] Table 1 Catalyst application

[0055] Apply times Reaction time / min selectivity / % Yield / % 1 30 99.1 93.4 2 30 99.5 91.8 3 32 99.4 95.2 4 30 99.5 94.9 5 35 99.0 92.3 6 37 99.9 93.1 7 37 99.9 93.8 8 38 99.7 92.6 9 40 99.1 93.2 10 40 99.8 91.7

[0056] The catalyst was used mechanically for 10 times, the reaction activity decreased slightly, but the selectivity and yield were basically stable.

Embodiment 3

[0058] According to the steps described in Example 1, the ratio of the PSMVK copolymer was adjusted to obtain immobilized catalysts with different monomer ratios, as shown in Table 2.

[0059] Table 2 Catalyst formula adjustment

[0060]

[0061] The obtained 1~7# catalysts were fed according to the 20% weight ratio of citral, and the reaction results are shown in Table 3.

[0062] Table 3 Catalytic activity

[0063]

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com