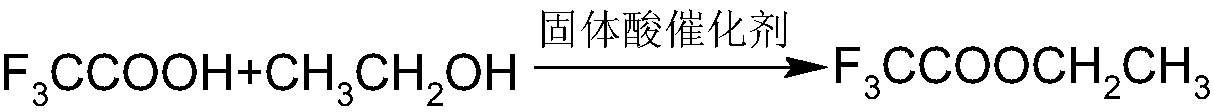

Method for synthesizing ethyl trifluoroacetate

A technology of ethyl trifluoroacetate and a synthesis method, which is applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problem that potassium hydrogen fluoride solid cannot be handled, trifluoroacetyl fluoride raw material is rare and unsuitable Industrial production and other problems, to achieve the effect of low overall cost control, thorough response, and simple equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] A kind of synthetic method of ethyl trifluoroacetate of example 1

[0023] Throw 100 grams (0.877mol) of trifluoroacetic acid, 42.5 grams (0.922mol) of absolute ethanol, in a 500 ml three-necked flask, add 5.5 grams (4.4mmol) of solid acid catalyst, the number of moles per gram of solid acid catalyst is 0.8mmol) , start stirring at 20°C and keep it warm for 8 hours, take a sample test, the trifluoroacetic acid is 0.48%, stop stirring, use a separatory funnel to remove the lower part of the water, transfer the upper material layer into a three-necked flask, put in 2.2 grams of solid acid catalyst, start stirring Continue to react for 1 hour at 20°C, take a sample for detection, 0.08% trifluoroacetic acid, after the reaction is complete, pour the feed liquid into another 500 ml three-necked flask, the flask is equipped with a 40 cm 24# caliber rectification column (glass spring packing), Start stirring, heat up and rectify; receive the distillate at 60-62°C to obtain 122....

example 2

[0024] A kind of synthetic method of ethyl trifluoroacetate of example 2

[0025] Throw 100 grams (0.877 mol) of trifluoroacetic acid and 42.5 grams (0.922 mol) of absolute ethanol into a 500 ml three-necked flask, add 5.5 grams of solid acid catalyst, start stirring at 30 ° C for 4 hours, and take samples for detection. Acetic acid 0.42% (required to be less than 0.5%), stop stirring, pour into a separatory funnel to separate the lower part of the water, transfer the upper material layer into a three-necked flask, put in 2.2 grams of solid acid catalyst, start stirring at 20 °C and continue the reaction for 1 hour, sampling and testing , trifluoroacetic acid 0.05% (required to be less than 0.1%), after completion of the reaction, feed liquid is poured in another 500 milliliters there-necked flask, the rectifying column (glass spring packing) of 40 centimeters of 24# calibers of flask assembly, start stirring, Heating rectification; receive the distillate at 60-62° C. to obtai...

example 3

[0026] A kind of synthetic method of ethyl trifluoroacetate of example 3

[0027] Throw 100 grams (0.877 mol) of trifluoroacetic acid and 42.5 grams (0.922 mol) of absolute ethanol into a 500 ml three-necked flask, add 8.0 grams of solid acid catalyst, start stirring at 30 ° C for 2 hours, and take samples for detection. Acetic acid 0.45% (required to be less than 0.5%), stop stirring, pour into a separatory funnel to separate the lower part of the water, transfer the upper material layer into a three-necked flask, put in 2.2 grams of solid acid catalyst, start stirring at 20 °C and continue the reaction for 1 hour, sampling and testing , trifluoroacetic acid 0.04% (required to be less than 0.1%), after completion of the reaction, feed liquid is poured in another 500 milliliters there-necked flask, and the rectifying column (glass spring packing) of 40 centimeters of 24# calibers of flask assembly, starts stirring, Heating rectification; receiving the distillate at 60-62° C. t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com