Catalyst for preparing cyclopentanone by aqueous phase hydrogenation of furfural or furfuryl alcohol and its preparation method and application method

A catalyst and hydrogen preparation technology, applied in chemical instruments and methods, preparation of carbon-based compounds, preparation of organic compounds, etc., can solve the problems of limited source of cyclopentene raw materials, low atom economy, and very side effects of catalysts. Good catalytic activity stability, improve catalytic efficiency, and facilitate separation, recovery and reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

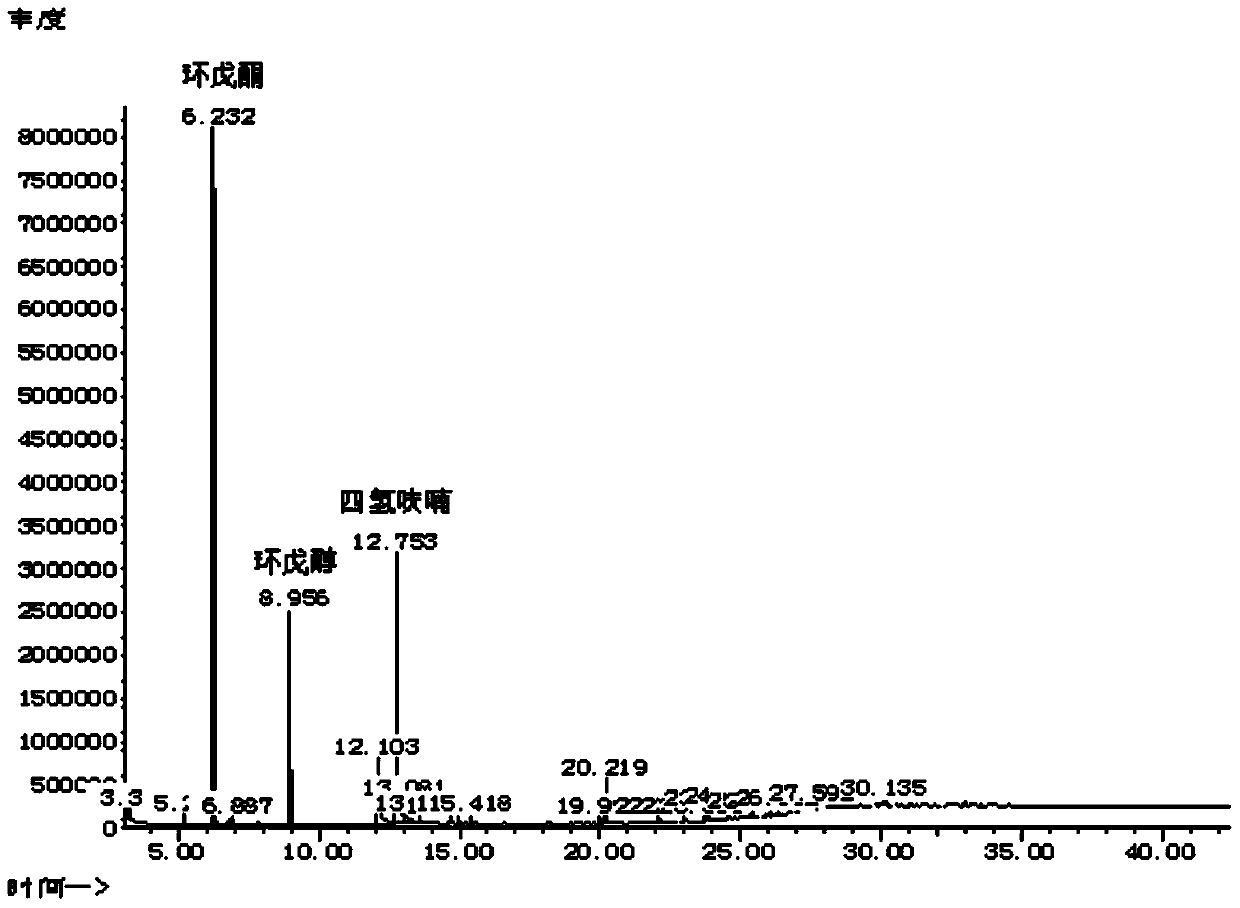

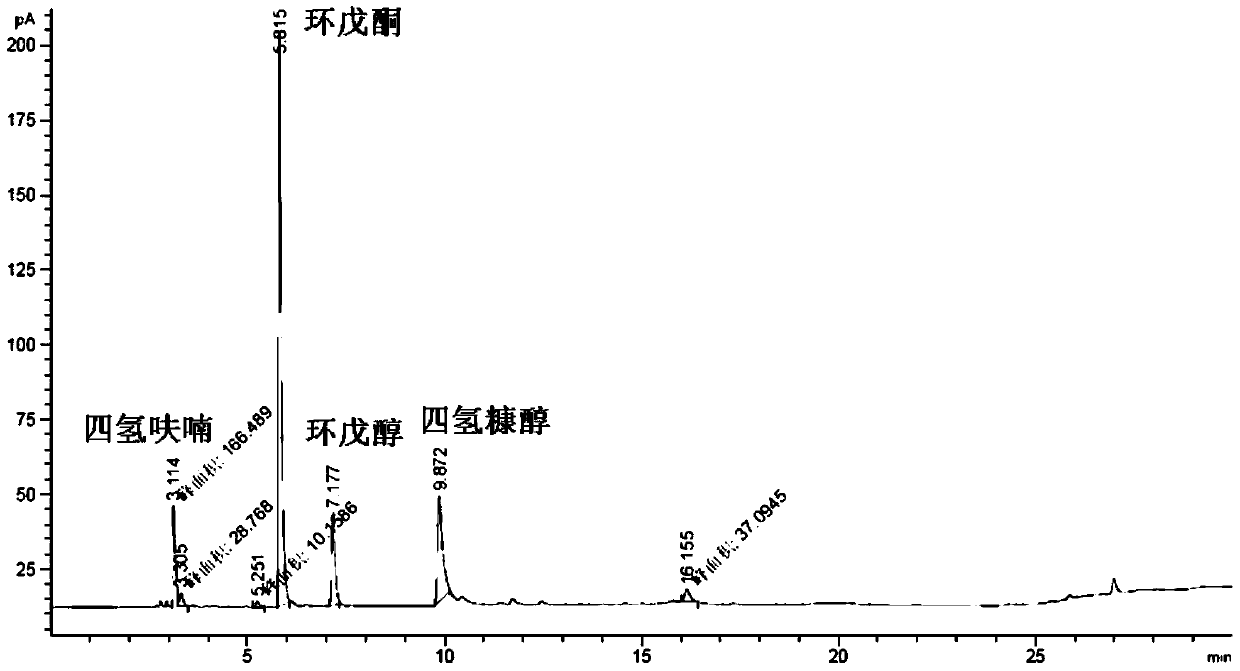

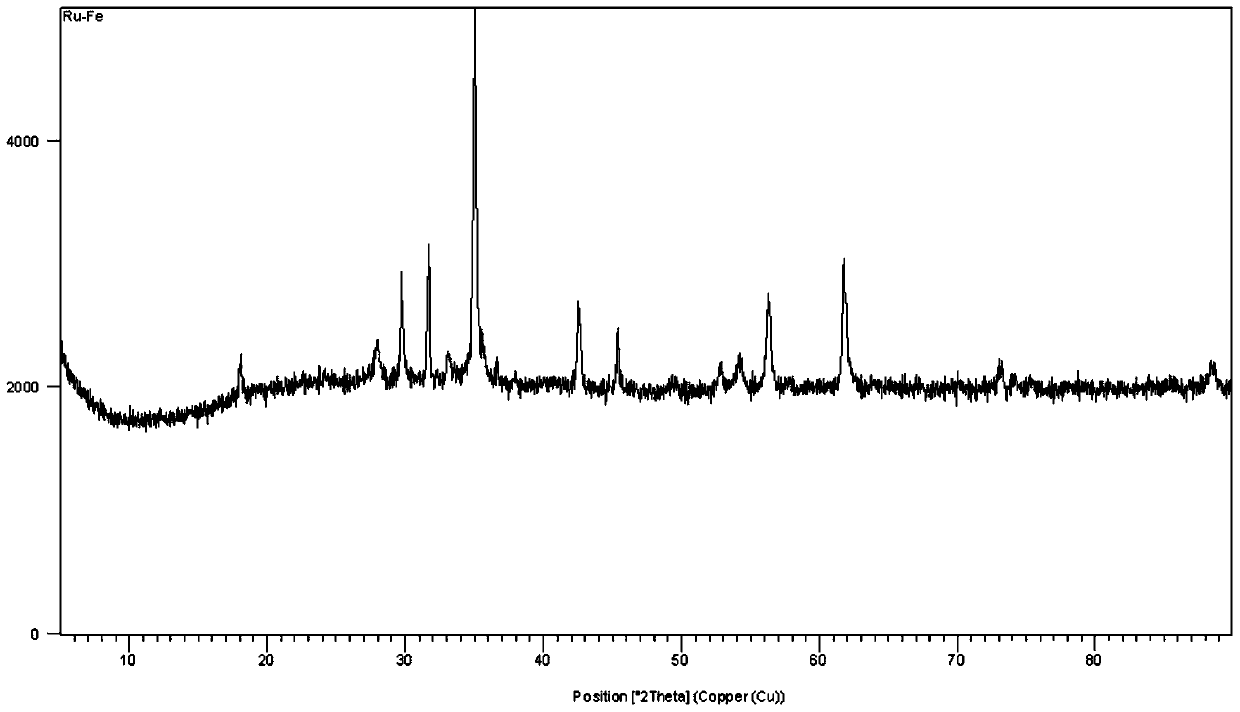

Embodiment 1

[0027] Catalyst preparation: (1) According to the methanol-water mass ratio of 1:1, make a mixed solvent, add ferric nitrate into the mixed solvent to dissolve and form ferric nitrate solution (referred to as solution A), and the molar concentration of ferric nitrate is 0.4mol / L; (2) with sodium carbonate aqueous solution (referred to as solution B), the molar concentration is 0.6mol / L; (3) solution B is gradually and slowly added to solution A, stirring while adding, along with the precipitation in the solution Gradually increase until the pH value in the mixed solution reaches 8-10, then stop. Then, the solution containing the precipitate after co-precipitation was aged for 12 hours, and finally filtered, washed, dried at 90°C for 48 hours, and calcined at 400°C for 48 hours in a muffle furnace to obtain a magnetic iron oxide (Fe y o x , 2 / 3y o x ) as the carrier, the equal volume impregnation method prepares the supported Ru catalyst, the quality of Ru is 4.0% of the car...

Embodiment 2

[0030] Catalyst preparation: (1) be made into mixed solvent at 1:2 by ethanol-water mass ratio, ferric chloride is added in mixed solvent and dissolves and forms ferric chloride solution (referred to as solution A), and the molar concentration of ferric chloride is 0.8mol / L; (2) with sodium carbonate aqueous solution (referred to as solution B), the molar concentration is 1.2mol / L; (3) gradually and slowly add solution B to solution A, stirring while adding, as the solution The precipitation in the solution gradually increases until the pH value in the mixed solution reaches 8-10, then it can be stopped. Then, the solution containing the precipitate after co-precipitation was aged for 24 hours, and finally filtered, washed, dried at 120°C for 24 hours, and calcined at 500°C for 24 hours in a muffle furnace to obtain a magnetic iron oxide (Fe y o x , 2 / 3y o x ) as the carrier, the equal volume impregnation method prepares the supported Ru catalyst, the quality of Ru is 4.0% o...

Embodiment 3

[0033] Catalyst preparation: (1) Make a mixed solvent according to the mass ratio of ethylene glycol-water at 1:2, add ferric nitrate into the mixed solvent to dissolve and form a ferric nitrate solution (referred to as solution A), and the molar concentration of ferric nitrate is 1.0 mol / L; (2) add sodium bicarbonate aqueous solution (referred to as solution B), and the molar concentration is 1.5mol / L; (3) gradually and slowly add solution B to solution A, stir while adding, as the solution The precipitation in the solution gradually increases until the pH value in the mixed solution reaches 8-10, then it can be stopped. Then, the solution containing the precipitate after co-precipitation was aged for 48 hours, and finally filtered, washed, dried at 100°C for 24 hours, and calcined at 600°C for 12 hours in a muffle furnace to obtain a magnetic iron oxide (Fe y o x , 2 / 3y o x ) as the carrier, the equal volume impregnation method prepares the supported Ru catalyst, the quali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com