Corner gearbox for single-rack driving steel pipe stretch reducing mill

A tension-reducing machine, single-stand technology, which is applied to the driving device of metal rolling mill, metal processing equipment, metal rolling, etc. The effect of passive water blocking function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

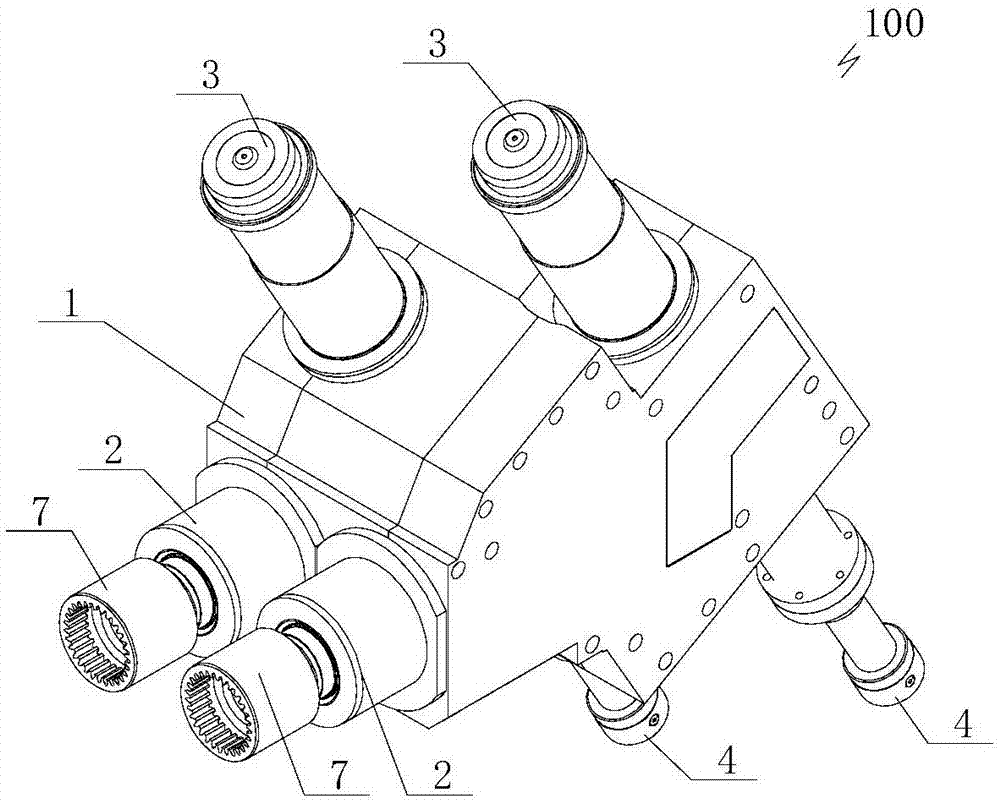

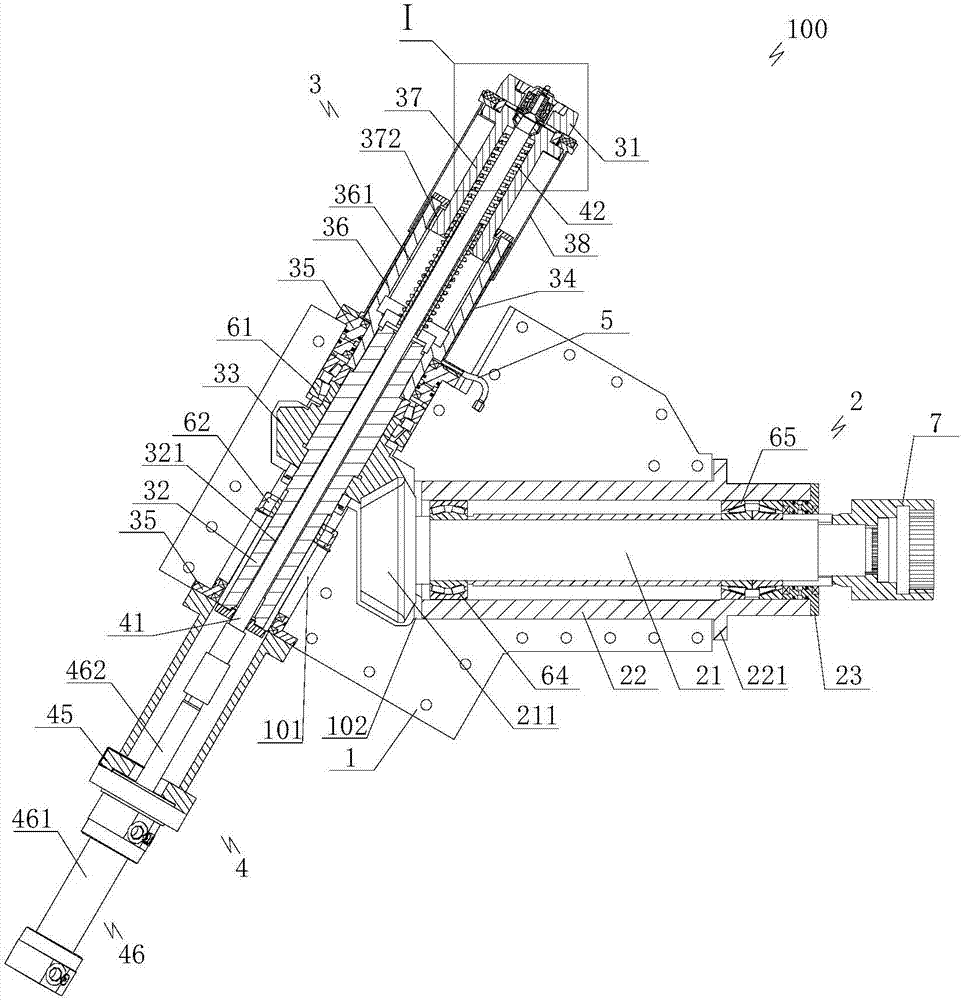

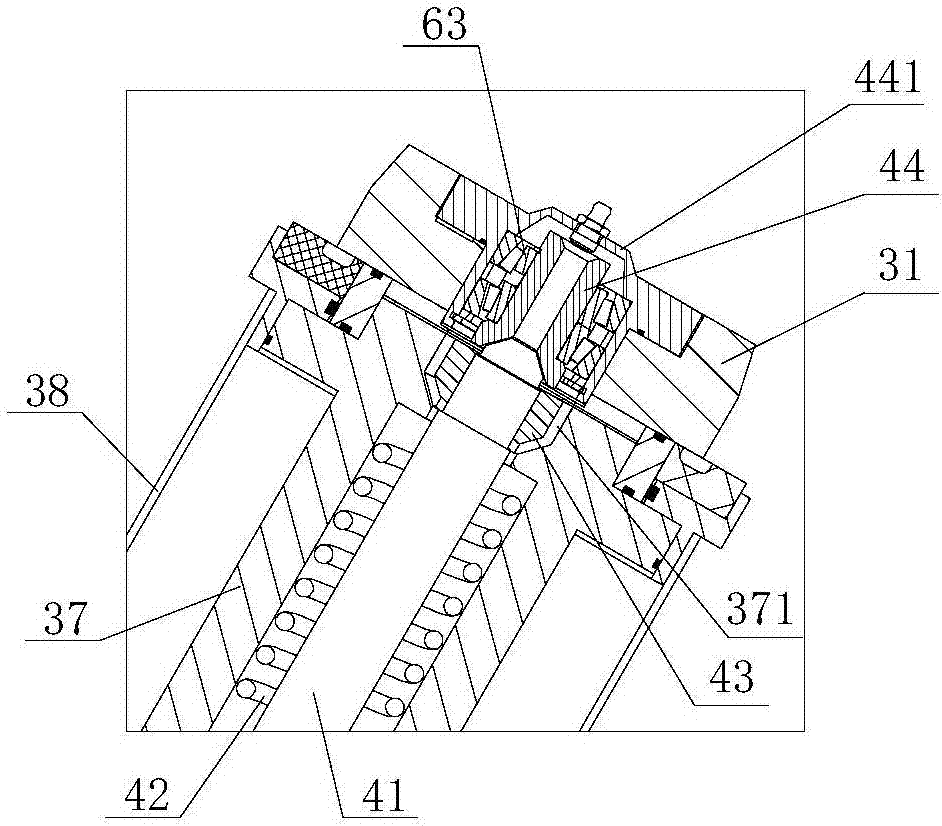

[0061] Such as Figure 1 to Figure 3 As shown, the present invention provides a corner gear box 100 for a single-frame transmission steel pipe tensioning machine, including a box body 1, and two groups of power transmission gear boxes with different rotation directions are arranged at intervals and are sealed and pierced inside the box body 1. Each power transmission system includes respectively a power input shafting 2 and a power output shafting 3 meshed by bevel gears, and the output end of each power output shafting 3 includes an energy and a rolling stand (prior art, Fig. not shown in ), the other end of each power output shaft system 3 is respectively connected with a telescopic control part 4, and each telescopic control p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com