Equal-tooth adjustment positioning device for iron plate of metal decorating machine

A technology for adjusting positioning and iron printing machines, applied to printing machines, general parts of printing machinery, printing, etc., can solve the problems of increasing machine debugging time and labor intensity, wasting iron sheets, etc., and achieve shortening overprinting time, improving work efficiency, and displacement Speed and position control for flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings.

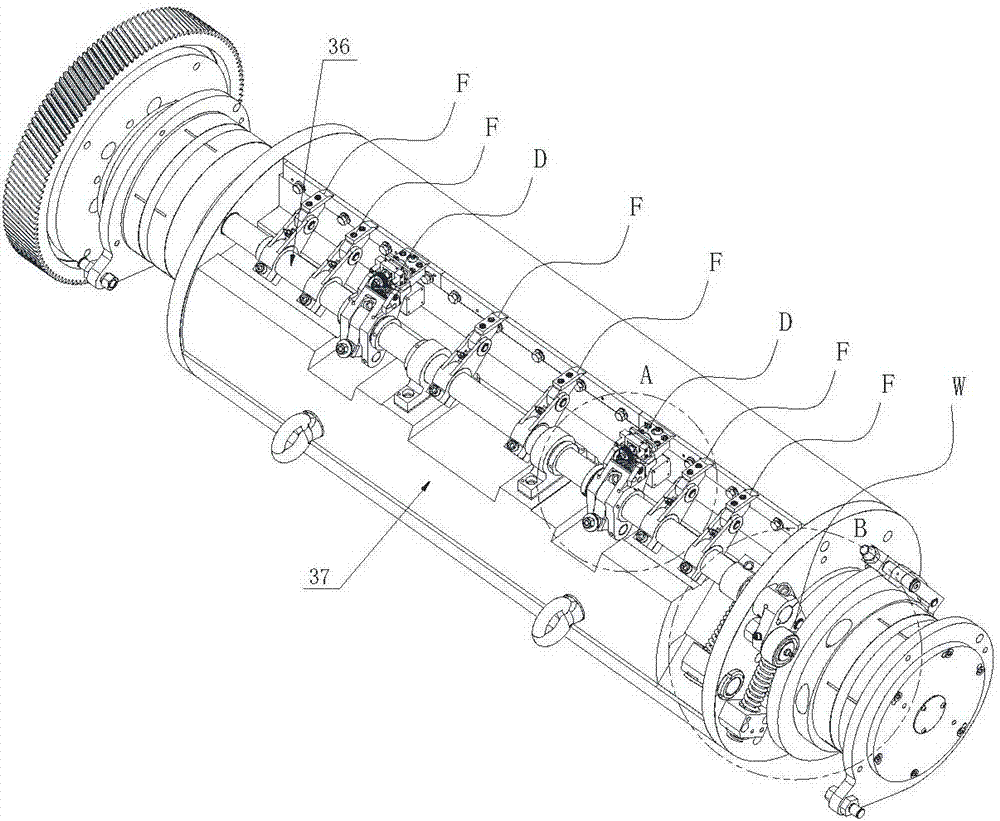

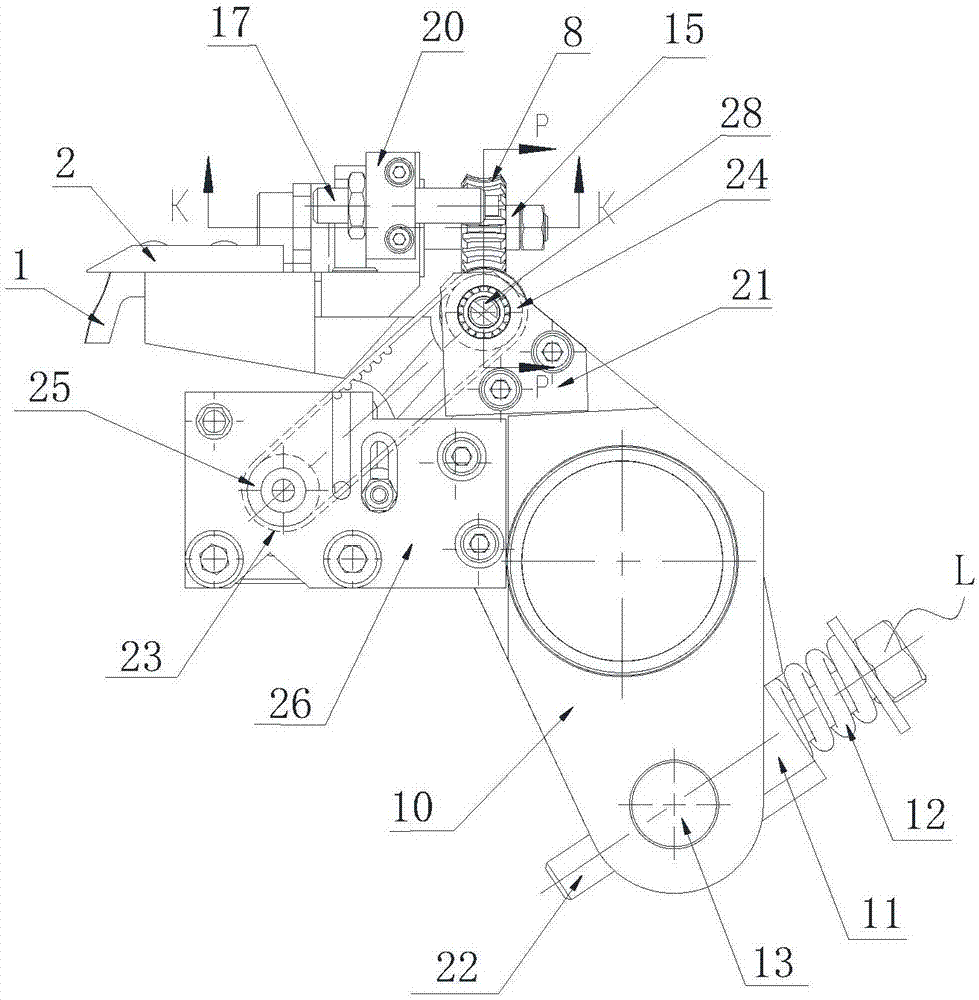

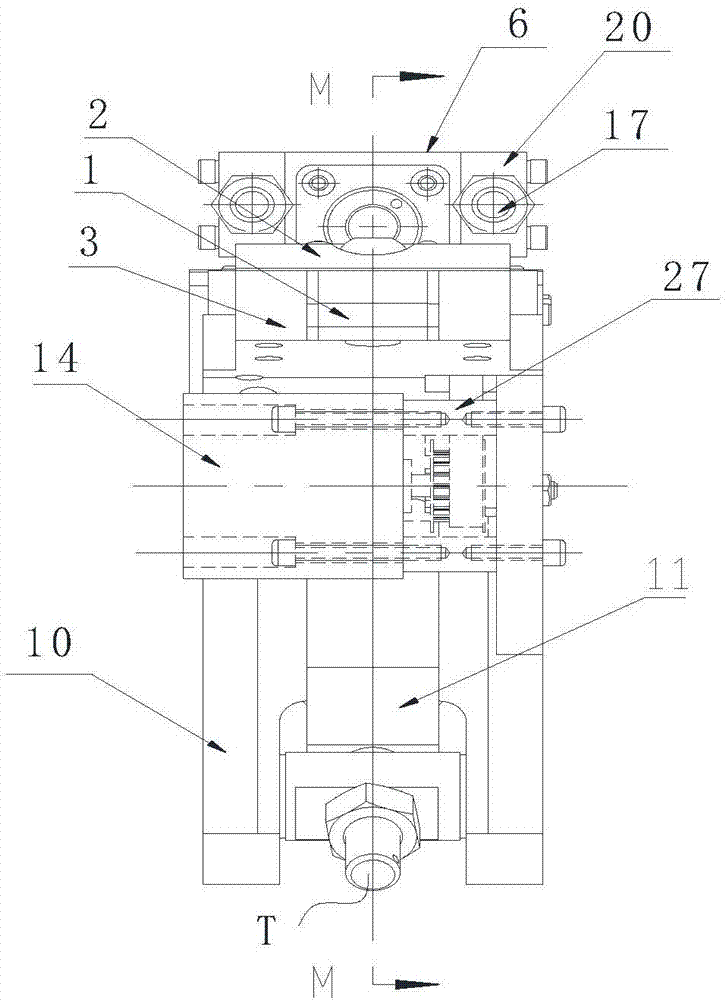

[0042] see figure 1 with figure 2 , with reference to Figure 3-10 , the figure shows a kind of tooth adjustment and positioning device for iron plate of iron printing machine related to the present invention, and the key technical solution adopted by it is:

[0043] The tooth adjusting and positioning device includes a toothing shaft 36 movable on the inside of the outer edge of the two axial ends of the impression cylinder 37. On the toothing shaft 36, there are several pairs of auxiliary toothing positioning mechanisms F arranged at intervals in the axial direction. A first-class tooth electric adjustment and positioning mechanism D is positioned on the teeth-grinding shaft 36 between the auxiliary teeth-grinding mechanisms F.

[0044] Such as Figure 2-7 As shown, the equal-tooth electric adjustment and positioning mechanism D includes a front gauge seat 10 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com