Self-flow injection method and self-flow injection molding barrel thereof

A filling port and barrel body technology, which is applied in the field of self-flow filling method and self-flow injection barrel, can solve the problems of waste, labor and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

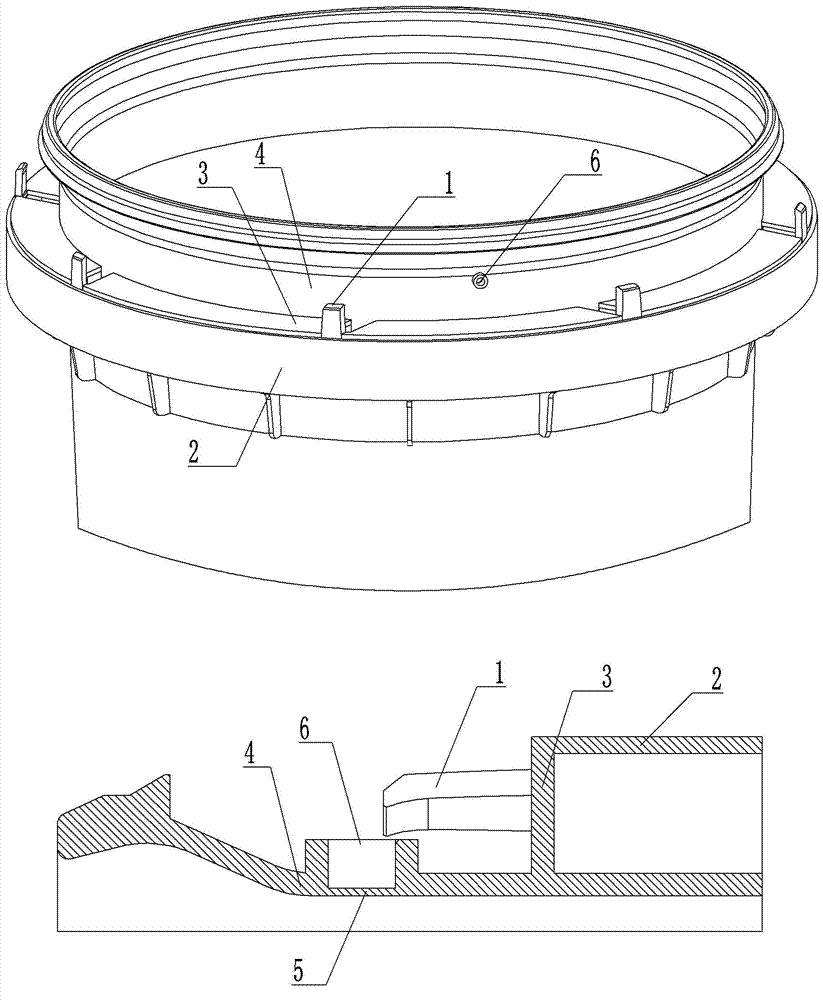

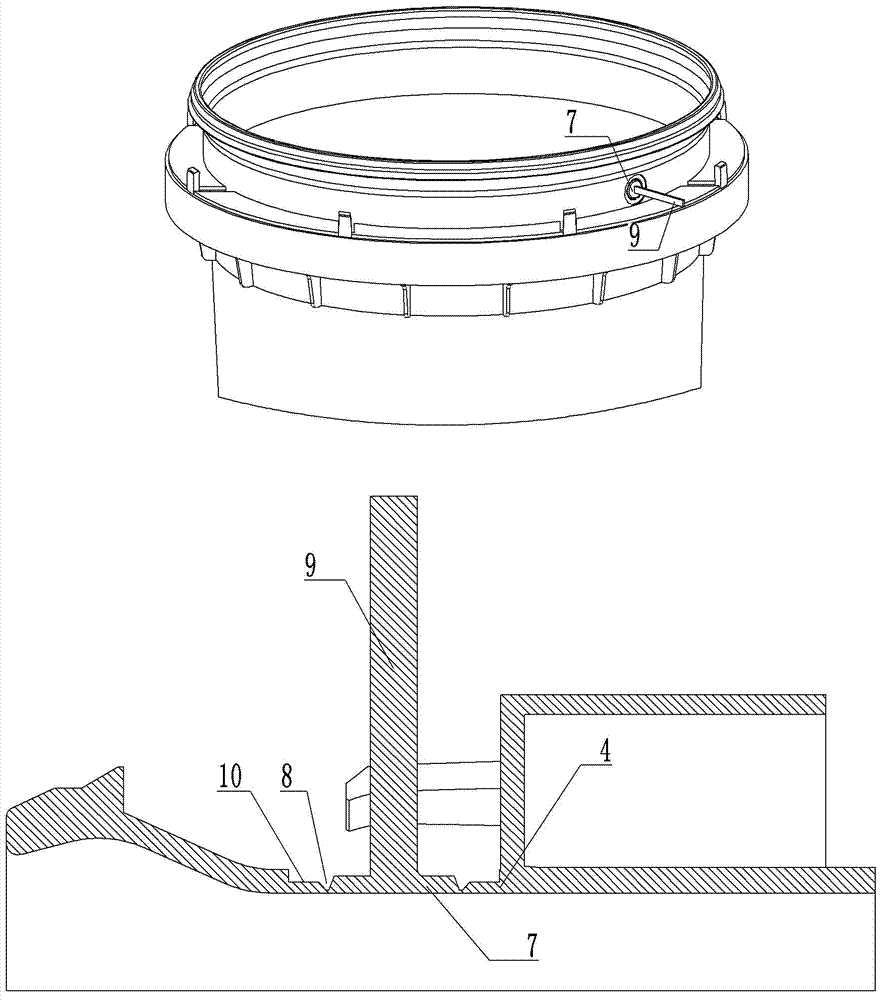

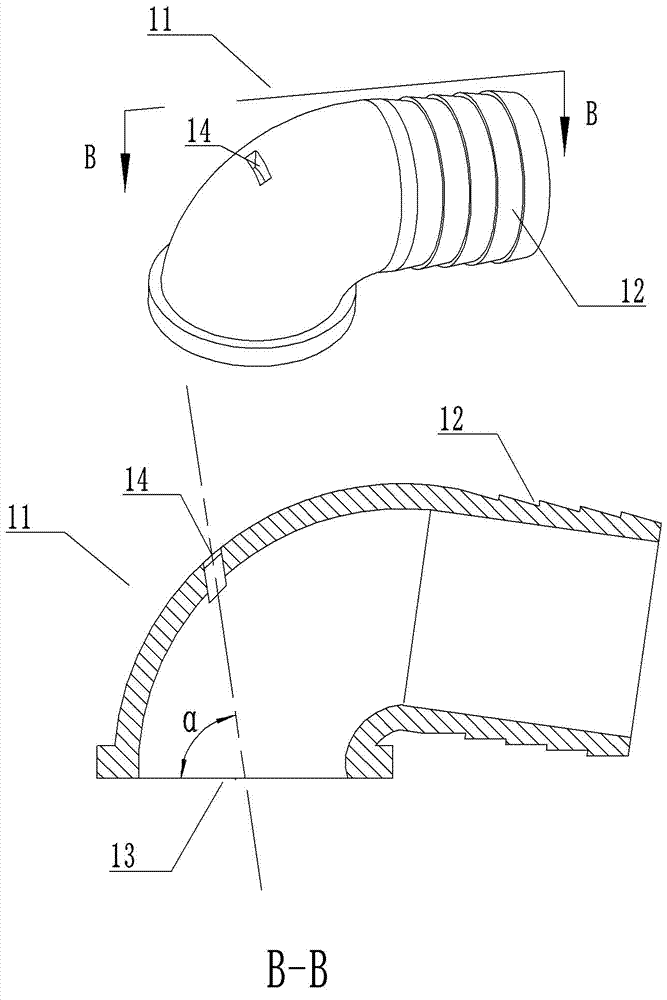

[0103] Embodiment 1, the self-flowing injection molding barrel is composed of a tube side-guided pull-belt diaphragm barrel body assembly with a pull-belt diaphragm as the sealing element, and the barrel cover is fastened, including a card tube side-guided pull-belt diaphragm barrel body, a soft conduit, The puncture needle, the side-guided pulling diaphragm barrel of the card tube is mainly composed of the carding claw, the pulling diaphragm, the venting blind hole, and the guide belt curved catheter. Its form is as follows: figure 1 As shown, the clamping claw 1 is a clamping device evenly arranged at the junction of the barrel body side skirt 2 and the side skirt step 3, and the barrel mouth side wall 4 is provided with a ventilating blind hole 6 with a sealing film 5, and the sealing film The thickness is set to 0.1-0.5mm; if figure 2 As shown, the pull belt diaphragm is arranged on the side wall of the barrel mouth and is connected with a pull belt. The diaphragm 7 is a ...

Embodiment 2

[0105] Embodiment 2, the self-flowing injection molding barrel is composed of a side-guided perforated diaphragm barrel body assembly with a perforated diaphragm as the sealing element and a barrel cover, including a side-guided perforated diaphragm barrel body, a flexible catheter, and a puncture needle. The body of the card tube side-guided perforated diaphragm barrel is mainly composed of a card tube claw, a ventilating blind hole, a perforated diaphragm, a guide belt type curved catheter, a pull ring type pull belt, and a pull belt buckle. Its form is as follows: figure 1 As shown, the clamping claw 1 is a clamping device evenly arranged at the junction of the barrel body side skirt 2 and the side skirt step 3, and the barrel mouth side wall 4 is provided with a ventilating blind hole 6 with a sealing film 5, and the sealing film The thickness is set to 0.1-0.5mm; the perforated diaphragm is a diaphragm with a tear-off hole set on the side wall of the barrel mouth, such as ...

Embodiment 3

[0107] Embodiment 3, the self-flowing injection molding barrel is composed of a side-guided hinged diaphragm barrel body assembly with a hinged diaphragm as the sealing element and a barrel cover, including a side-guided hinged diaphragm barrel body, a flexible catheter, and a puncture needle. The side-guided hinged diaphragm barrel of the card tube is mainly composed of the card tube claw, the blind hole for ventilation, the hinge diaphragm, the guide rod type curved pipe, and the ejector rod. Its form is as follows: figure 1 As shown, the clamping claw 1 is a clamping device evenly arranged at the junction of the barrel body side skirt 2 and the side skirt step 3, and the barrel mouth side wall 4 is provided with a ventilating blind hole 6 with a sealing film 5, and the sealing film The thickness of the barrel is set to 0.1-0.5mm; the hinge diaphragm is a diaphragm with a hinge body and a baffle set on the side wall of the barrel mouth, such as Figure 15 As shown, the diaph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com