Wine bottle cap overturning and righting structure

A wine bottle cap, rotating fulcrum technology, applied in the directions of bottle cap pretreatment, bottle/container cap, bottle filling, etc., can solve the problems of unsuitable batch production and processing, irregular placement, and high production and manufacturing costs. To achieve the effect of convenient automatic processing, consistent placement, and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

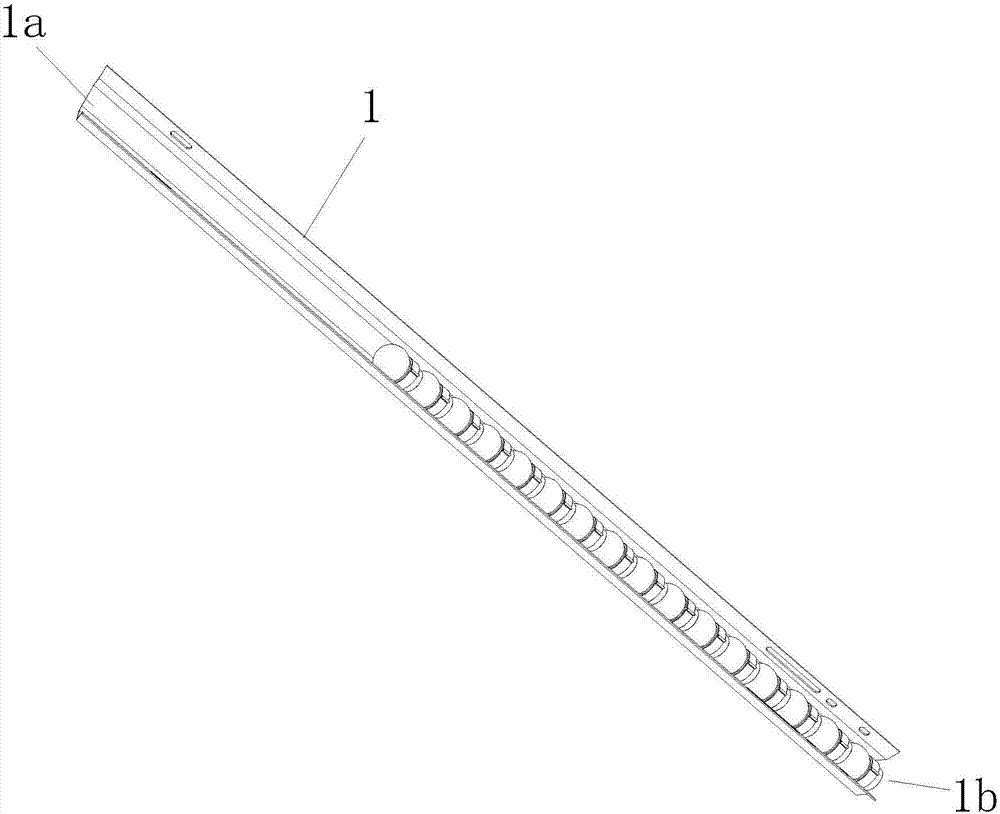

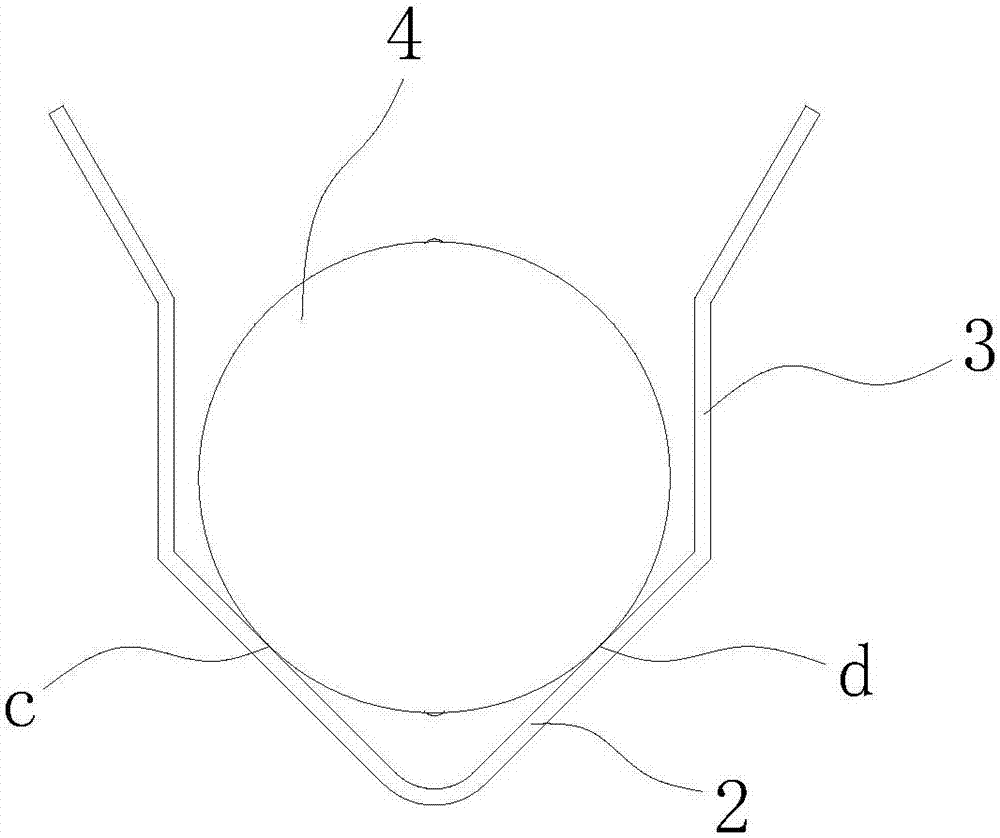

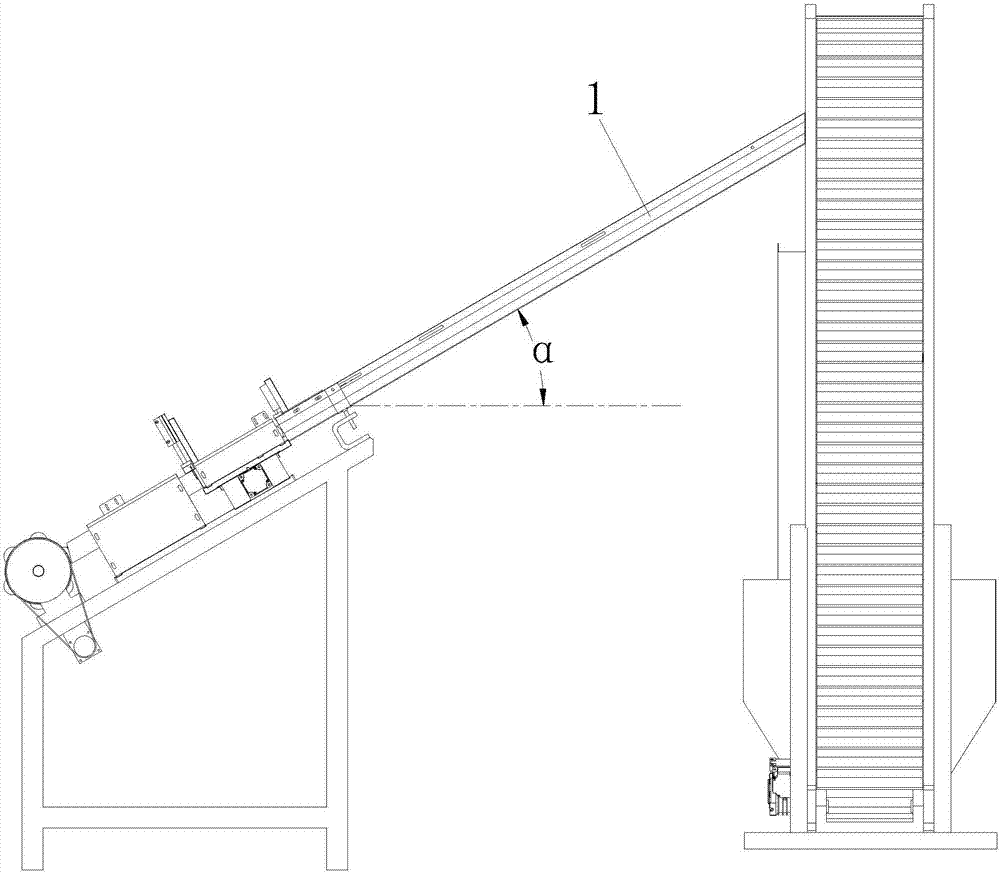

[0015] Such as figure 1 and figure 2 As shown, the wine bottle cap flip righting structure includes a slideway 1 with an input end 1a and an output end 1b; the input end 1a of the slideway 1 is used to input the wine bottle cap 4; the slideway 1 extends along its direction The inclination of the wine bottle cap 4 is configured so that the wine bottle cap 4 can be turned over with the points c and d where the ball head contacts the slideway as the fulcrum of rotation during the sliding process of the wine bottle cap 4, until the ball head faces upwards and continues to slide, and the Exhaust 1b.

[0016] The bottom of the slideway 1 is provided with a V-shaped folded bottom plate 2. The ball head of the wine bottle cap can be lifted up by using the V-shaped folded bottom plate 2. Fli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com