Selective Separation and Comprehensive Recovery of Nickel in Alkaline Chemical Nickel Wastewater

A recovery method and chemical nickel technology, applied in chemical instruments and methods, optics, water pollutants, etc., can solve the problem that the effluent is difficult to achieve the standard, and achieve the effect of increasing the adsorption concentration ratio, realizing comprehensive recovery and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further explain the content of the present invention, the present invention is described in detail in conjunction with examples, and these examples are only suitable for illustrating the present invention and do not limit the application scope of the present invention.

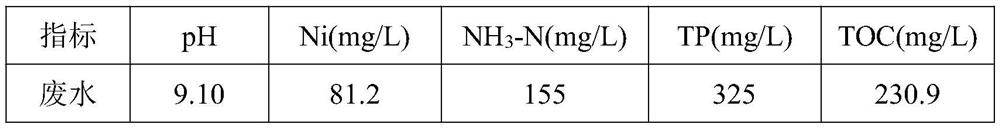

[0042] Application of the present invention to process alkaline chemical nickel waste water and aging liquid of enterprise A, the water quality analysis of alkaline chemical nickel waste water and aging liquid in enterprise A is as shown in Table 1.

[0043] Table 1 Water quality analysis of low temperature alkaline chemical nickel workshop wastewater and aging solution

[0044]

[0045]

[0046] Among them, the phosphorus content in the form of hypophosphite in the wastewater is 125mg / L. Through Visual MINTEQ software analysis, it can be seen that the main complexed form of Ni is NiNH 3 + and Ni(NH 3 ) 2 + .

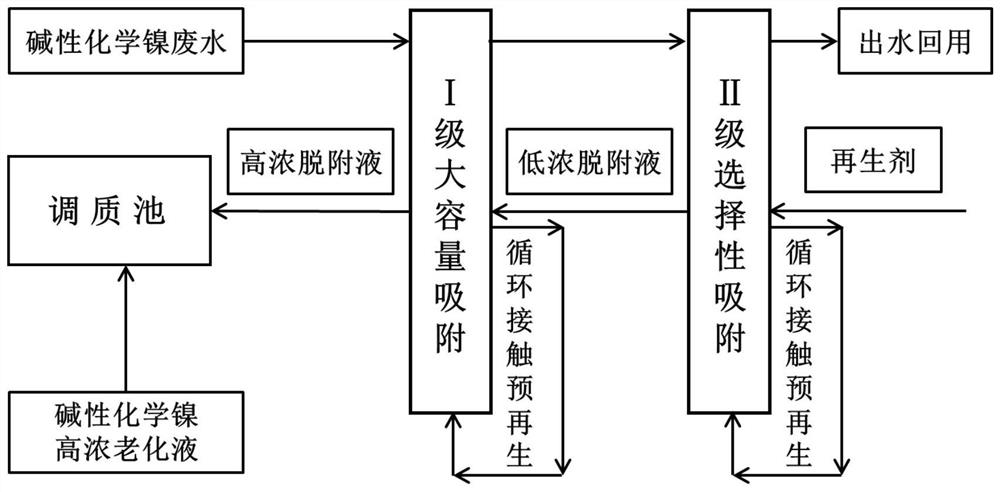

[0047]1. "Class I large-capacity adsorption + Class II selective adso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com