Automatic clutch driving mechanism, engine and motorcycle

A driving mechanism, automatic clutch technology, applied in the direction of mechanical drive clutches, clutches, mechanical equipment, etc., can solve the problems of large driving stroke of the clutch control rocker arm, low driving efficiency of the clutch cam disc, and complicated force conditions, and improve the driving force. force, avoid large driving resistance, and improve the effect of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

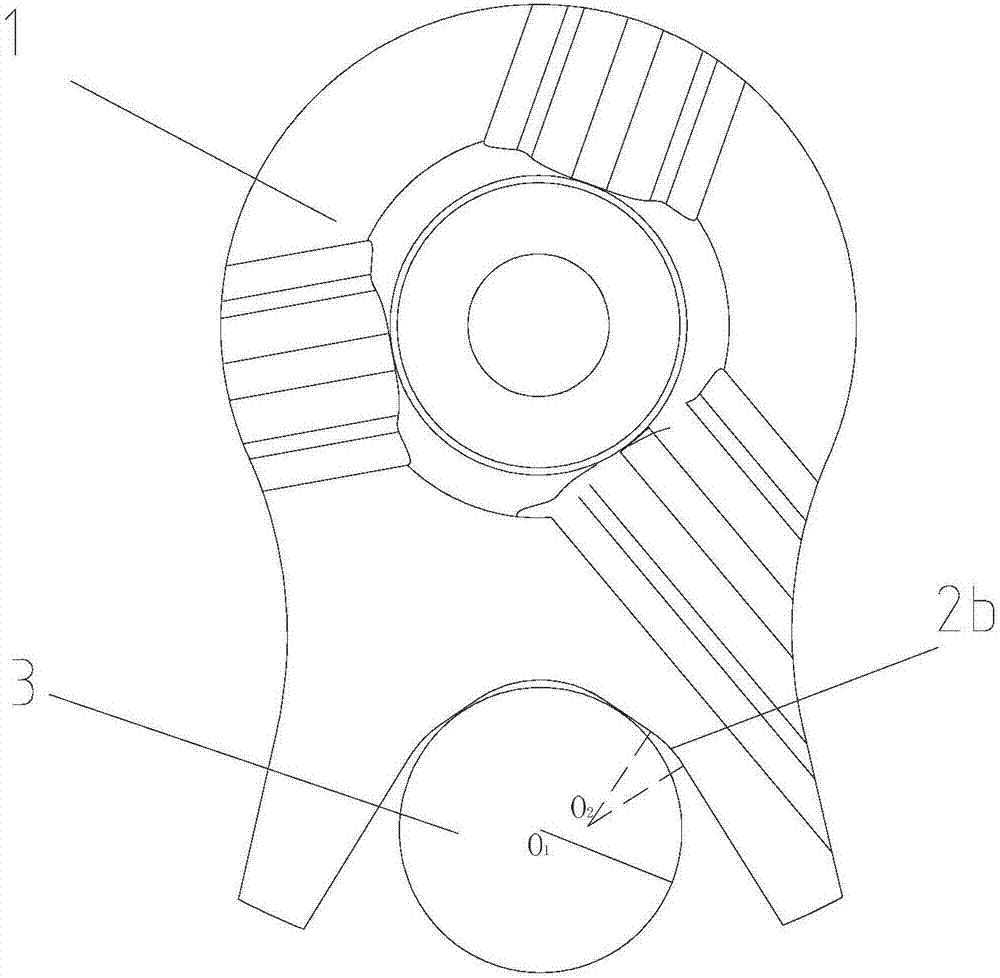

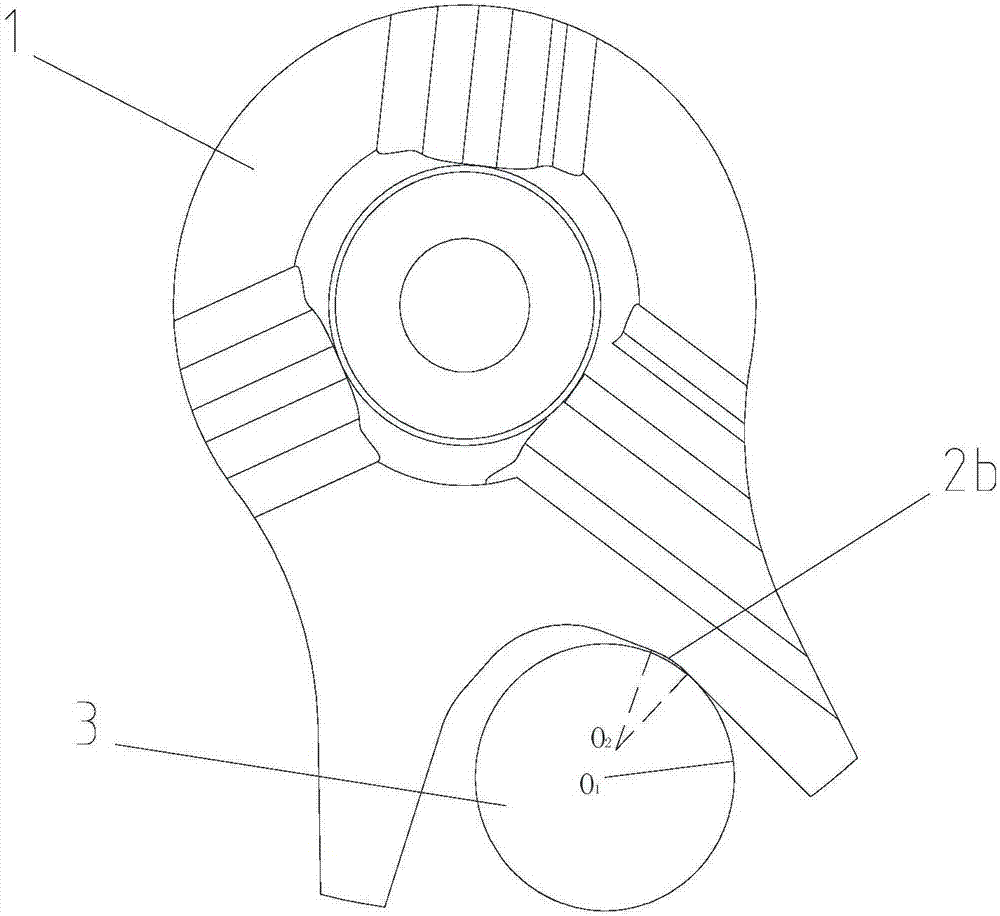

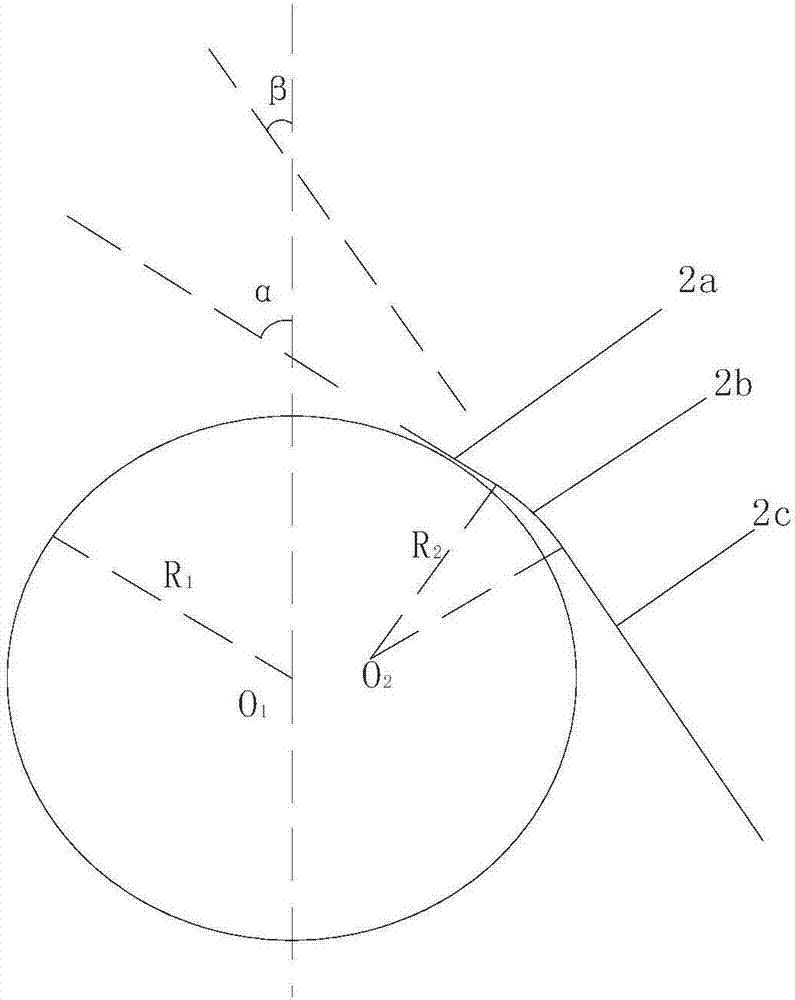

[0021] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a structural schematic diagram after the rotation of the clutch cam disc in the present invention, image 3 It is a structural schematic diagram of the medium-sized wire of the present invention, Figure 4 It is a structural schematic diagram of the engine in the present invention. As shown in the figure, the automatic clutch drive mechanism in this embodiment includes a clutch cam plate and a clutch control rocker arm, the clutch cam plate is provided with an opening groove, and the clutch control rocker arm The clutch cam plate is driven to rotate through the open slot to complete the clutch; the curve formed by the cross section of the open slot on its side wall is the driving profile, which is symmetrical as a whole and gradually becomes larger from the inside to the outside , the single side of the driving line includes the first straight line and the curved line from inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com