Cylinder block bore hole seam allowance end face bouncing degree and flatness gauge

A technology of end face runout and cylinder block, which is used in mechanical roughness/irregularity measurement, mechanical clearance measurement, etc., can solve the problems of large measurement error and troublesome measurement, and achieve the effect of simple structure and improved inspection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

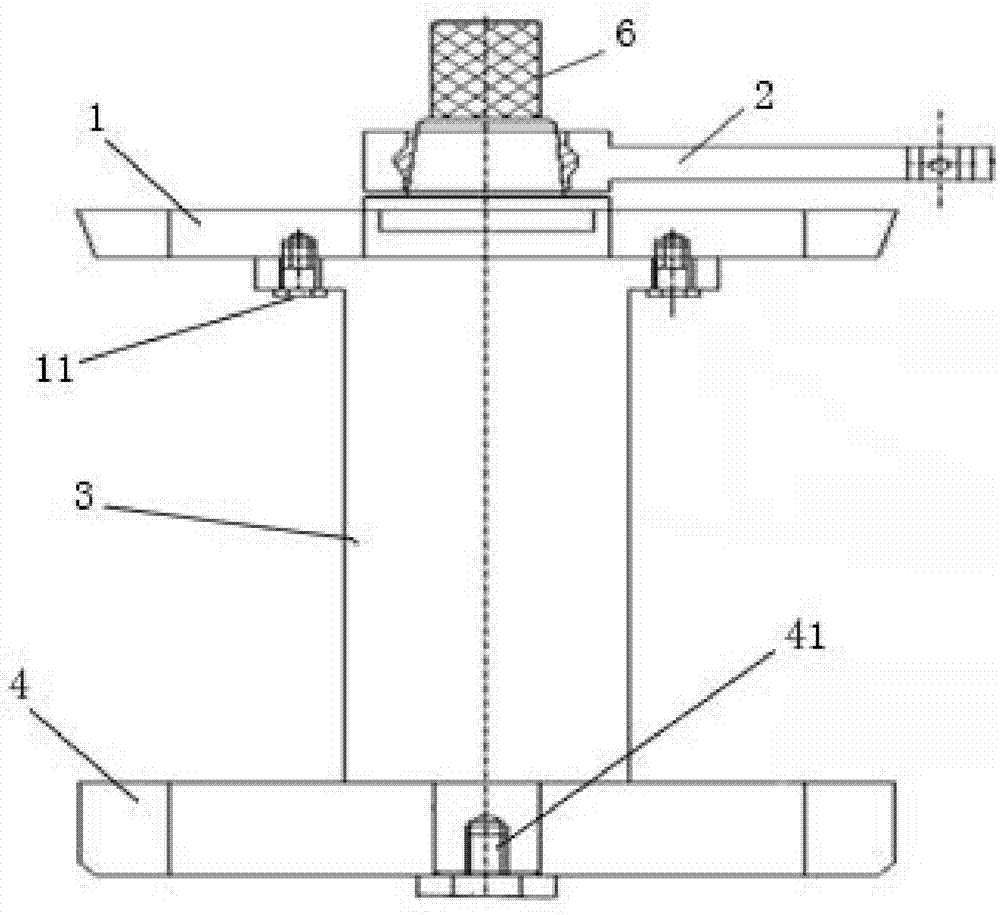

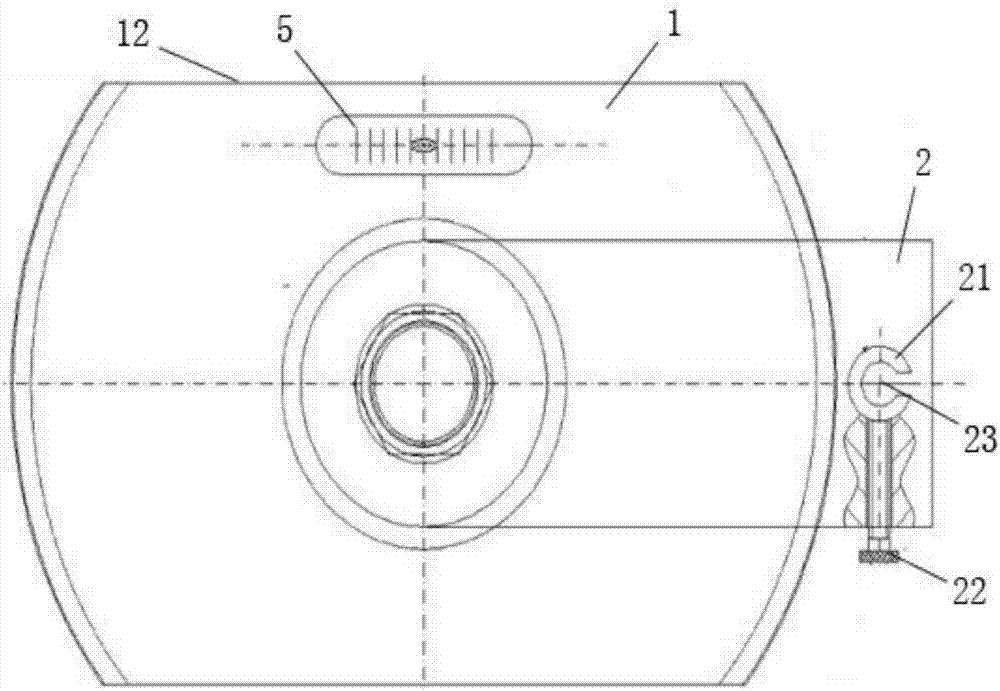

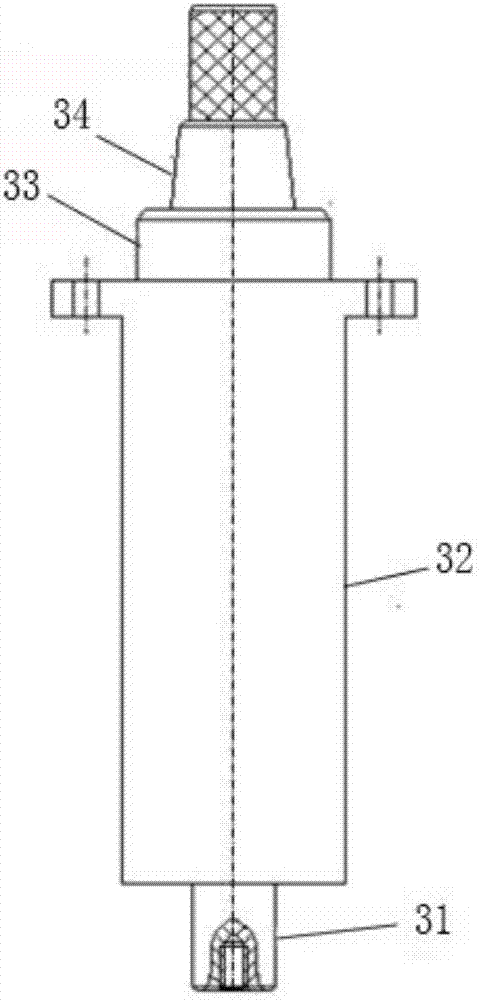

[0023] A test tool for the runout and flatness of the end face of the cylinder bore seam of a cylinder block, including a support shaft 3, a guide stub 4, a measuring tool, and a gauge frame 2, the guide stub 4 is combined with the lower end of the support shaft 3, and a taper reference plate 1. The watch frame 2 is combined on the upper end of the support shaft 3; the taper reference plate 1 is combined on the upper part of the support shaft 3 and between the watch frame 2 and the guide short column 4. The measuring tool is a dial gauge and is assembled on the right end of the meter frame 2, and the dial gauge measuring head points to the cylinder bore spigot plane and ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com