Collimating backlight structure

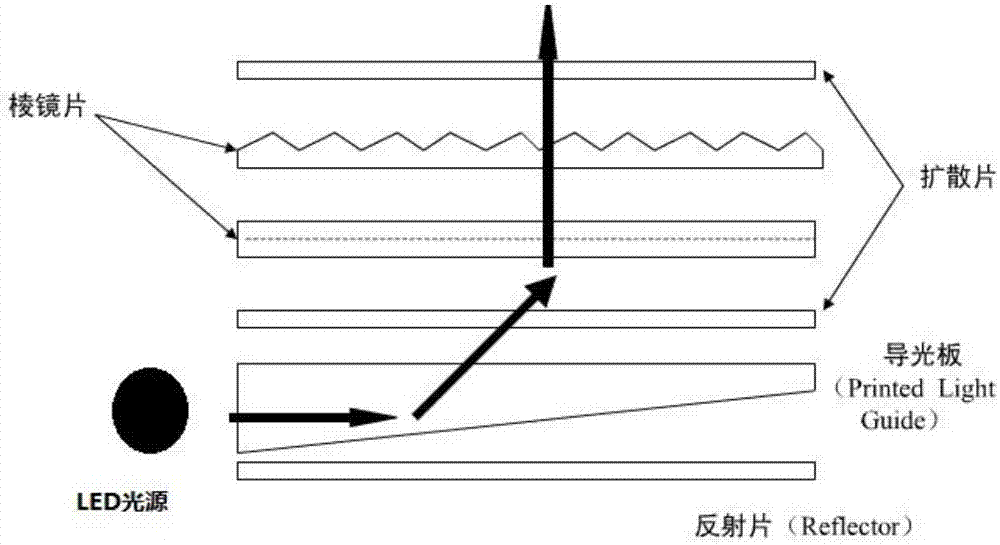

A backlight structure and microstructure technology, applied in the field of collimated backlight, can solve the problems of destroying total reflection conditions, difficult to obtain collimated surface light source, limited convergence effect of prism sheet on the divergence angle of backlight emitted light, etc., to achieve backlight structure. Simple, brightening effect of the backlight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

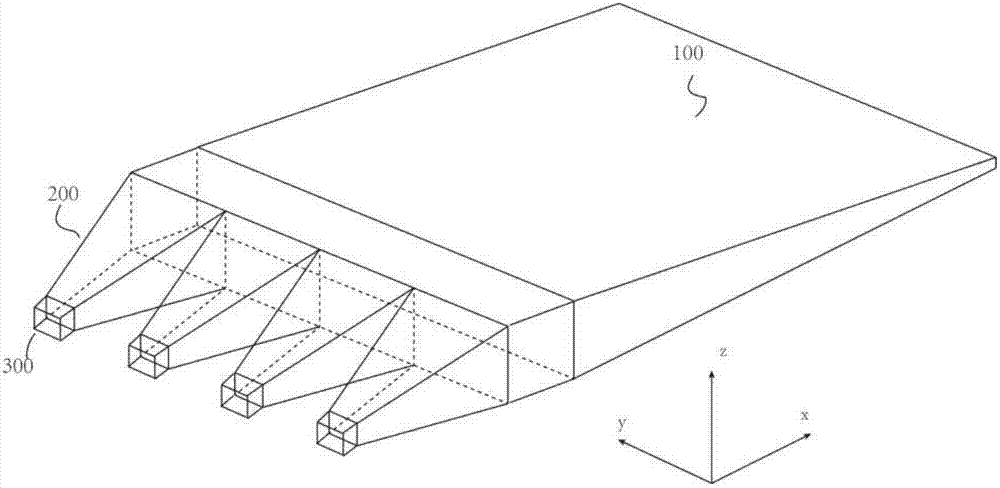

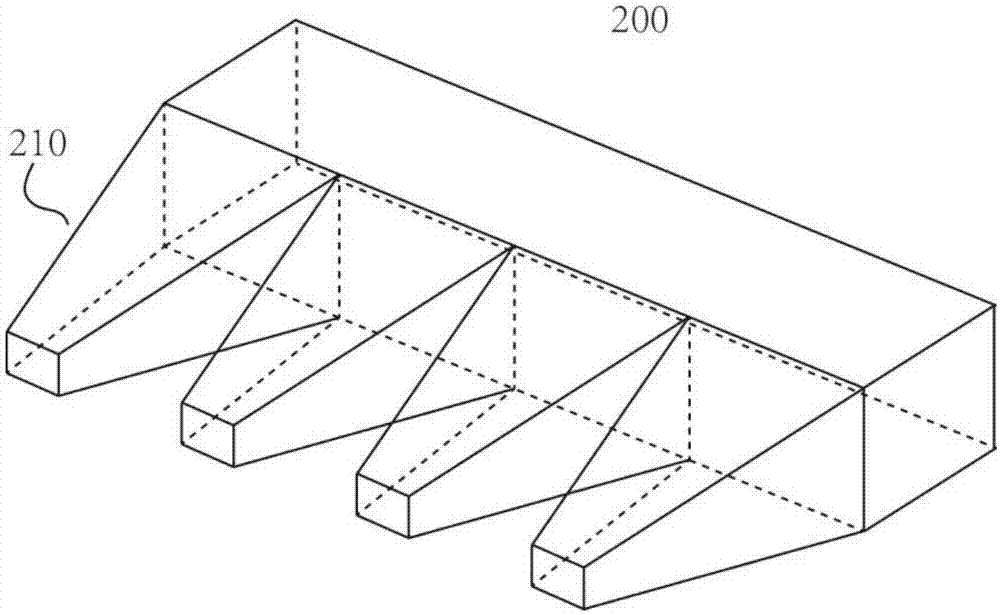

[0028] The collimated backlight structure disclosed by the present invention is as figure 2 As shown, it includes a light guide plate 100 , a light collimating component 200 and an LED light source array 300 . The structure of the light collimation component 200 is as follows: image 3 As shown, an array of light pipes 210 is included. The structure of the light guide is as Figure 4 As shown, it is a square tapered light pipe. The incident surface of the light pipe is 211, the outgoing surface is 212, and the surrounding surface is 213. The light pipe is a solid structure, the material is PMMA, and the surrounding surface of the light pipe is coated with 213 There is a metal reflective layer. As a preferred solution of the present invention, the incident surface and the outgoing surface of the light pipe are square, the side length of the light pipe incident surface is a1, the side length of the outgoing surface is a2, and the length of the light pipe is L, a2 =3*a1, L=1...

Embodiment 2

[0031] The collimated backlight structure disclosed by the present invention is as Figure 10 As shown, it includes a light guide plate 100 , a light collimating component 200 and an LED light source array 300 . The structure of the light collimation component 200 is as follows: Figure 11 As shown, an array of light pipes 210 is included. The structure of the light guide is as Figure 12 As shown, it is a conical light pipe, the incident surface of the light pipe is 211, the exit surface is 212, and the surrounding surface is 213. The light pipe is a hollow core structure, and the material is PMMA. Surface 213 is coated with a metallic reflective layer. As a preferred solution of the present invention, the incident surface and the outgoing surface of the light pipe are circular, the diameter of the light pipe incident surface is a1, the diameter of the outgoing surface is a2, and the length of the light pipe is L, a2= 4*a1, L=20*a1. The LEDs are arranged in one-to-one co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com